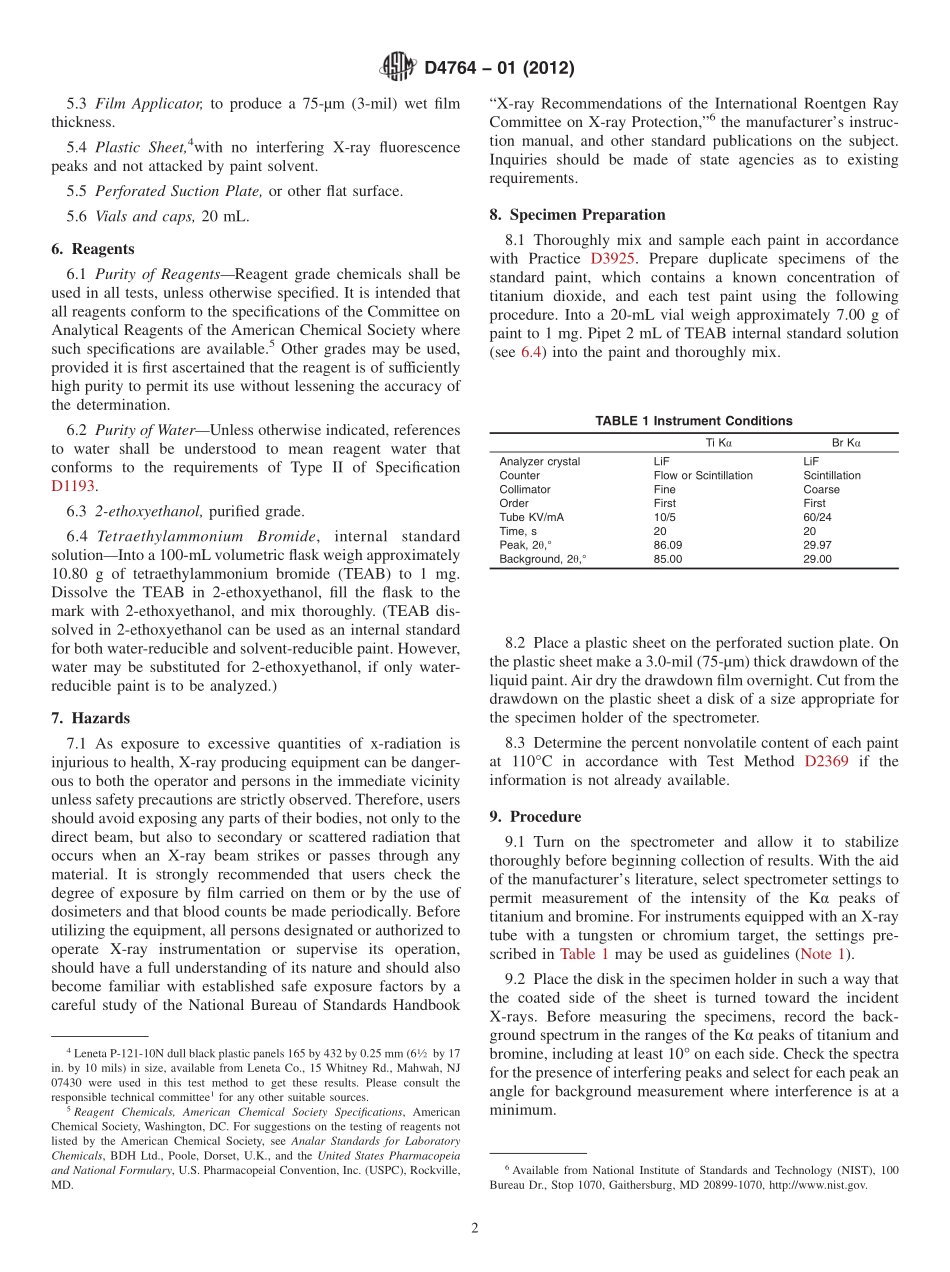

Designation:D4764−01(Reapproved2012)StandardTestMethodforDeterminationbyX-rayFluorescenceSpectroscopyofTitaniumDioxideContentinPaint1ThisstandardisissuedunderthefixeddesignationD4764;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthedeterminationoftitaniumdioxidecontentinliquidpaint.Thistestmethodisapplicabletobothwater-reducibleandsolvent-reduciblepaints.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.SpecifichazardsstatementsaregiveninSection7.2.ReferencedDocuments2.1ASTMStandards:2D1193SpecificationforReagentWaterD1394TestMethodsforChemicalAnalysisofWhiteTita-niumPigmentsD2369TestMethodforVolatileContentofCoatingsD3925PracticeforSamplingLiquidPaintsandRelatedPigmentedCoatingsD3980PracticeforInterlaboratoryTestingofPaintandRelatedMaterials(Withdrawn1998)3E180PracticeforDeterminingthePrecisionofASTMMethodsforAnalysisandTestingofIndustrialandSpe-cialtyChemicals(Withdrawn2009)33.SummaryofTestMethod3.1Paintcontainingaknownamountoftitaniumdioxideisusedasthereferencestandard.Asolutionoftetraethylammo-niumbromidein2-ethoxyethanolisaddedtothestandardpaintandtoeachpaintbeinganalyzed.Drawdownfilmsofthestandardandtestpaintaremadeonthinplasticsheets.TheintensitiesofkeyX-rayfluorescencepeaksoftitaniumandbrominearemeasured.Thetitaniumdioxidecontentisdeter-minedbycomparingtheratiooftheintensitiesoftitaniumandbrominepeaksinthetestpaintandthestandard.Differencesinthenonvolatilecontentofthepaintsaretakenintoaccountinthecalculationofresults.4.Signifi...