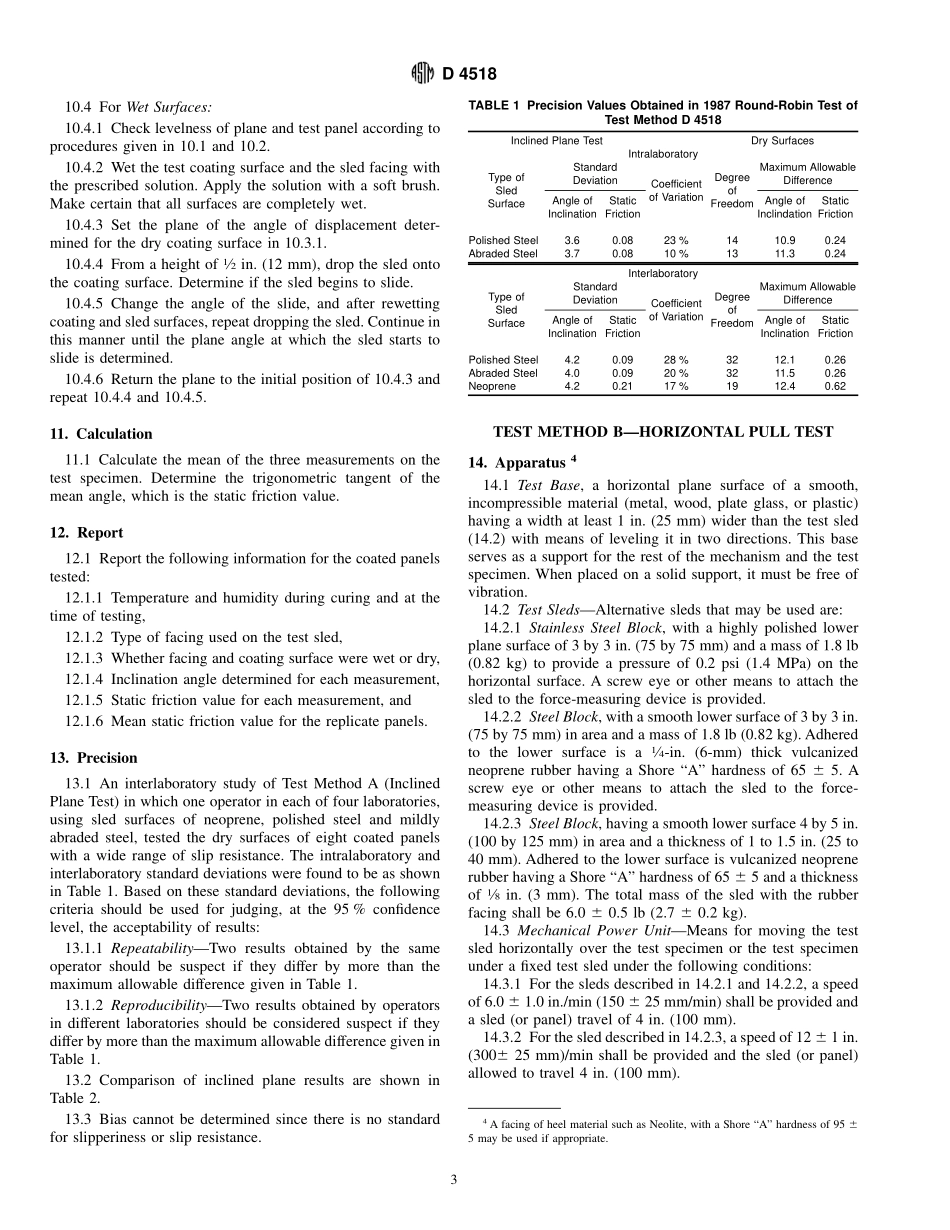

Designation:D4518–91StandardTestMethodsforMeasuringStaticFrictionofCoatingSurfaces1ThisstandardisissuedunderthefixeddesignationD4518;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thesetestmethodscoverthedeterminationoftheresistancetoslidingoncoatingsurfacesbymeasuringthestaticfriction.1.2Twotestmethodsaredescribedasfollows:SectionsMethodA—InclinedPlaneTest8-13MethodB—HorizontalPullTest14-191.3Thisstandarddoesnotpurporttoaddressallofthesafetyproblems,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:D823TestMethodsforProducingFilmsofUniformThick-nessofPaint,Varnish,andRelatedProductsonTestPanels23.Terminology3.1Definition:3.1.1staticfriction—theforcerequiredtostartthetestsledmoving,dividedbythemassofthesled.4.SummaryofTestMethods4.1Withtheinclinedplanetest(TestMethodA),aweightedsledisplacedonatestspecimenandthespecimenisgraduallyinclinedfromthehorizontaluntilthesledbeginstoslide.Thetangentofthisangleofinclinationisreportedasthestaticfriction.4.2Withthehorizontalpulltest(TestMethodB),aweightedsledisplacedonahorizontaltestspecimenandispulledacrossthespecimen.Thestaticfrictionisreportedastheforcerequiredtostartthesledmoving,dividedbythemassofthesled.5.SignificanceandUse5.1Thefrictioncharacteristicsofcoatingsurfacescanbeimportanttotheuseofthecoatings.Forexample,lowfrictionofexteriorcancoatingsisbeneficialtotheflowofthecansonproductionlines.Alsolowfrictionofinteriorpipelinecoatingsisbeneficialtotheflowofmaterialsthroughpipes.Ontheotherhand,lowfrictionoffloorcoatingscanbehazardoustofoottraffic.5.2Undersomeconditions,measurementofthestaticfrictioncanbeusedtoevaluatetheslipresistanceofc...