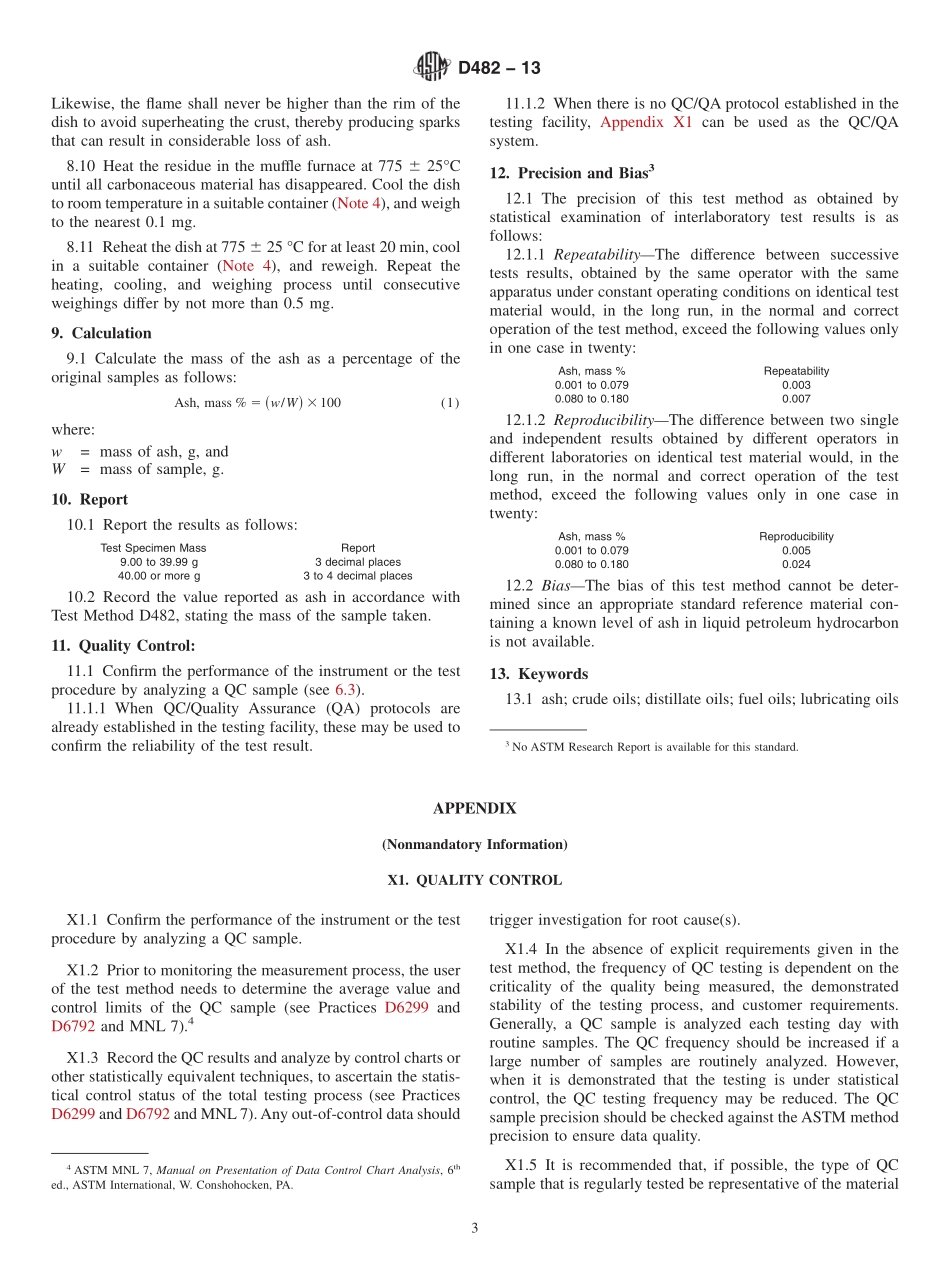

Designation:D482−13Designation:4/96StandardTestMethodforAshfromPetroleumProducts1ThisstandardisissuedunderthefixeddesignationD482;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope*1.1Thistestmethodcoversthedeterminationofashintherange0.001–0.180mass%,fromdistillateandresidualfuels,gasturbinefuels,crudeoils,lubricatingoils,waxes,andotherpetroleumproducts,inwhichanyash-formingmaterialspres-entarenormallyconsideredtobeundesirableimpuritiesorcontaminants(Note1).Thetestmethodislimitedtopetroleumproductswhicharefreefromaddedash-formingadditives,includingcertainphosphoruscompounds(Note2).NOTE1—Incertaintypesofsamples,alloftheash-formingmetalsarenotretainedquantitativelyintheash.Thisisparticularlytrueofdistillateoils,whichrequireaspecialashprocedureinordertoretainmetalsquantitatively.NOTE2—Thistestmethodisnotintendedfortheanalysisofunusedlubricatingoilscontainingadditives;forsuchsamplesuseTestMethodD874.Neitherisitintendedfortheanalysisoflubricatingoilscontainingleadnorforusedenginecrankcaseoils.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.Thepreferredexpressionofthepropertyismass%.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D874TestMethodforSulfatedAshfromLubricatingOilsandAdditivesD4057PracticeforManualSamplingofPetroleumandPetroleumProductsD4177PracticeforAutomaticSamplingofPetroleumandPetroleumProductsD4928TestMethodforWaterinCrudeOilsbyCoulometricKarlFischerTitrationD6299PracticeforApplyin...