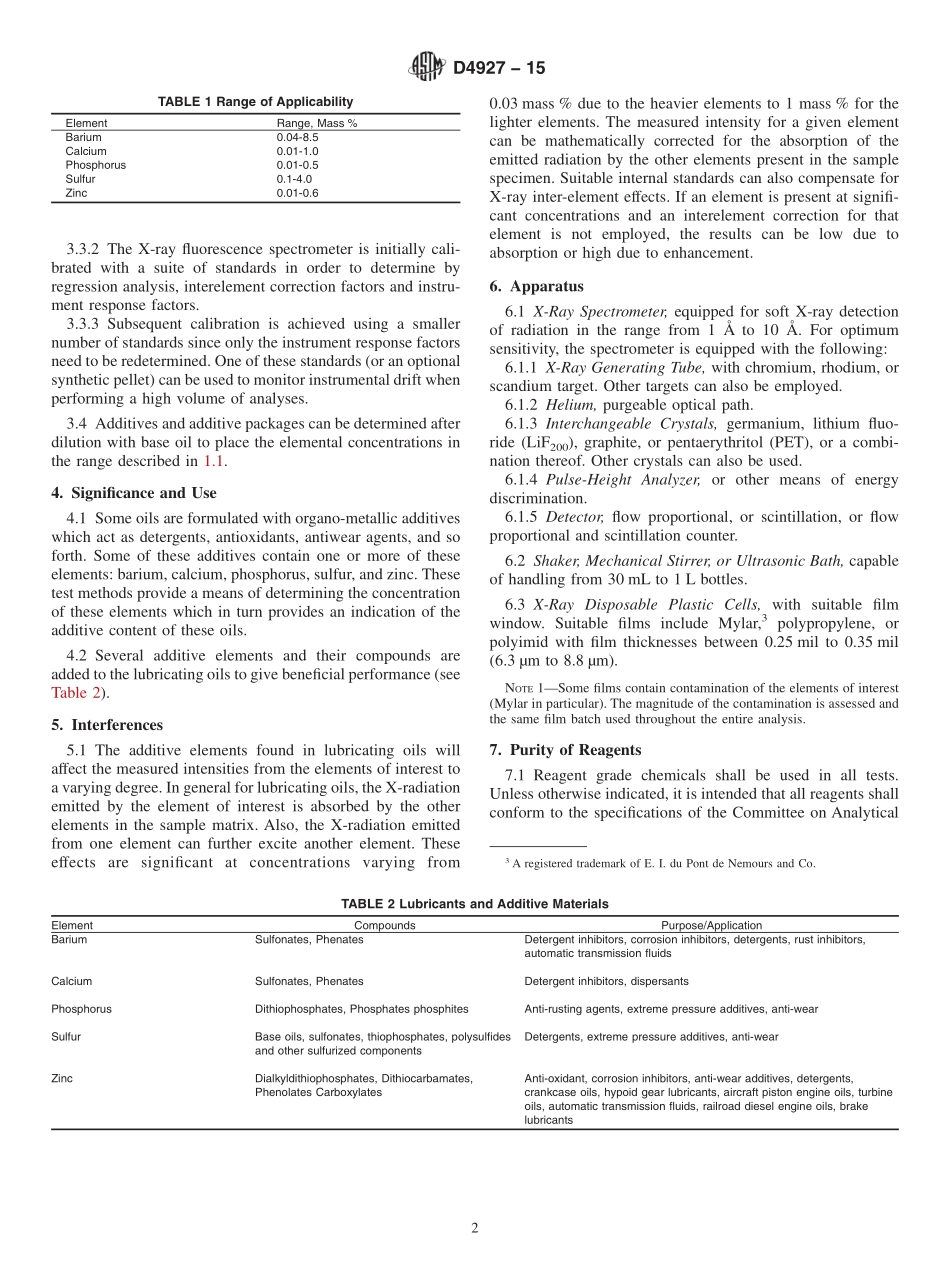

Designation:D4927−15StandardTestMethodsforElementalAnalysisofLubricantandAdditiveComponents—Barium,Calcium,Phosphorus,Sulfur,andZincbyWavelength-DispersiveX-RayFluorescenceSpectroscopy1ThisstandardisissuedunderthefixeddesignationD4927;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope*1.1Thesetestmethodscoverthedeterminationofbarium,calcium,phosphorus,sulfur,andzincinunusedlubricatingoilsatelementconcentrationrangesshowninTable1.Therangecanbeextendedtohigherconcentrationsbydilutionofsamplespecimens.Additivescanalsobedeterminedafterdilution.Twodifferentmethodsarepresentedinthesetestmethods.1.2TestMethodA(InternalStandardProcedure)—InternalstandardsareusedtocompensateforinterelementeffectsofX-rayexcitationandfluorescence(seeSections8through13).1.3TestMethodB(MathematicalCorrectionProcedure)—ThemeasuredX-rayfluorescenceintensityforagivenelementismathematicallycorrectedforpotentialinterferencefromotherelementspresentinthesample(seeSections14through19).1.4Thepreferredconcentrationunitsaremass%barium,calcium,phosphorus,sulfur,orzinc.1.5Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D6299PracticeforApplyingStatisticalQualityAssuranceandControlChartingTechniquestoEvaluateAnalyticalMeasurementSystemPerformance3.SummaryoftheTestMethods3.1AsamplespecimenisplacedintheX-raybeamandtheintensityoftheappropriatefluorescencelinesofbarium,calcium,phosphorus,sulfur,andzincaremeasured.Instrumentresponsefactorsrelatedtotheconcentrationofstandardsenablethedeterminationofthec...