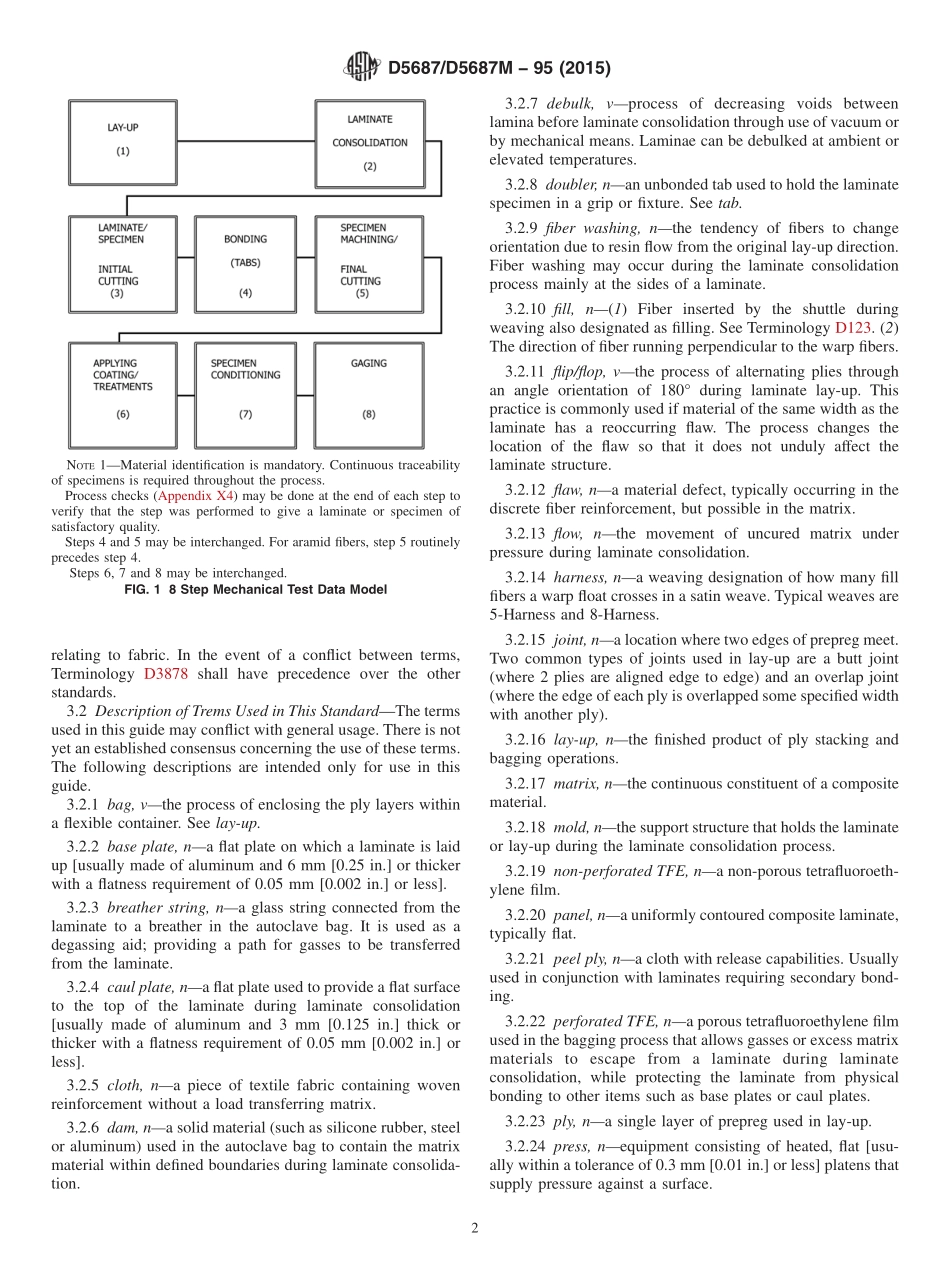

Designation:D5687/D5687M−95(Reapproved2015)StandardGuideforPreparationofFlatCompositePanelswithProcessingGuidelinesforSpecimenPreparation1ThisstandardisissuedunderthefixeddesignationD5687/D5687M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisguideprovidesguidelinestofacilitatetheproperpreparationoflaminatesandtestspecimensfromfiber-reinforcedorganicmatrixcompositeprepregs.Thescopeislimitedtoorganicmatricesandfiberreinforcementinunidi-rectional(tape)ororthagonalweavepatterns.Otherformsmayrequiredeviationsfromthesegeneralguidelines.Otherpro-cessingtechniquesfortestcouponpreparation,forexample,pultrusion,filamentwindingandresin-transfermolding,arenotaddressed.1.2Specimenpreparationismodeledasan8-stepprocessthatispresentedinFig.1andSection8.Laminateconsolida-tiontechniquesareassumedtobebypressorautoclave.Thispracticeassumesthatthematerialsareproperlyhandledbythetestfacilitytomeettherequirementsspecifiedbythematerialsupplier(s)orspecification,orboth.Identificationandinfor-mationgatheringguidelinesaremodeledafterGuideE1309.TestspecimensshallbedirectlytraceabletomaterialusedasdesignatedinGuideE1434.Propertestspecimenidentificationalsoincludesdesignationofprocessequipment,processsteps,andanyirregularitiesidentifiedduringprocessing.1.3ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Withinthetexttheinch-poundunitsareshowninbrackets.Thevaluesstatedineachsystemarenotexactequivalents;therefore,eachsystemmustbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnonconformancewiththestandard.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregula...