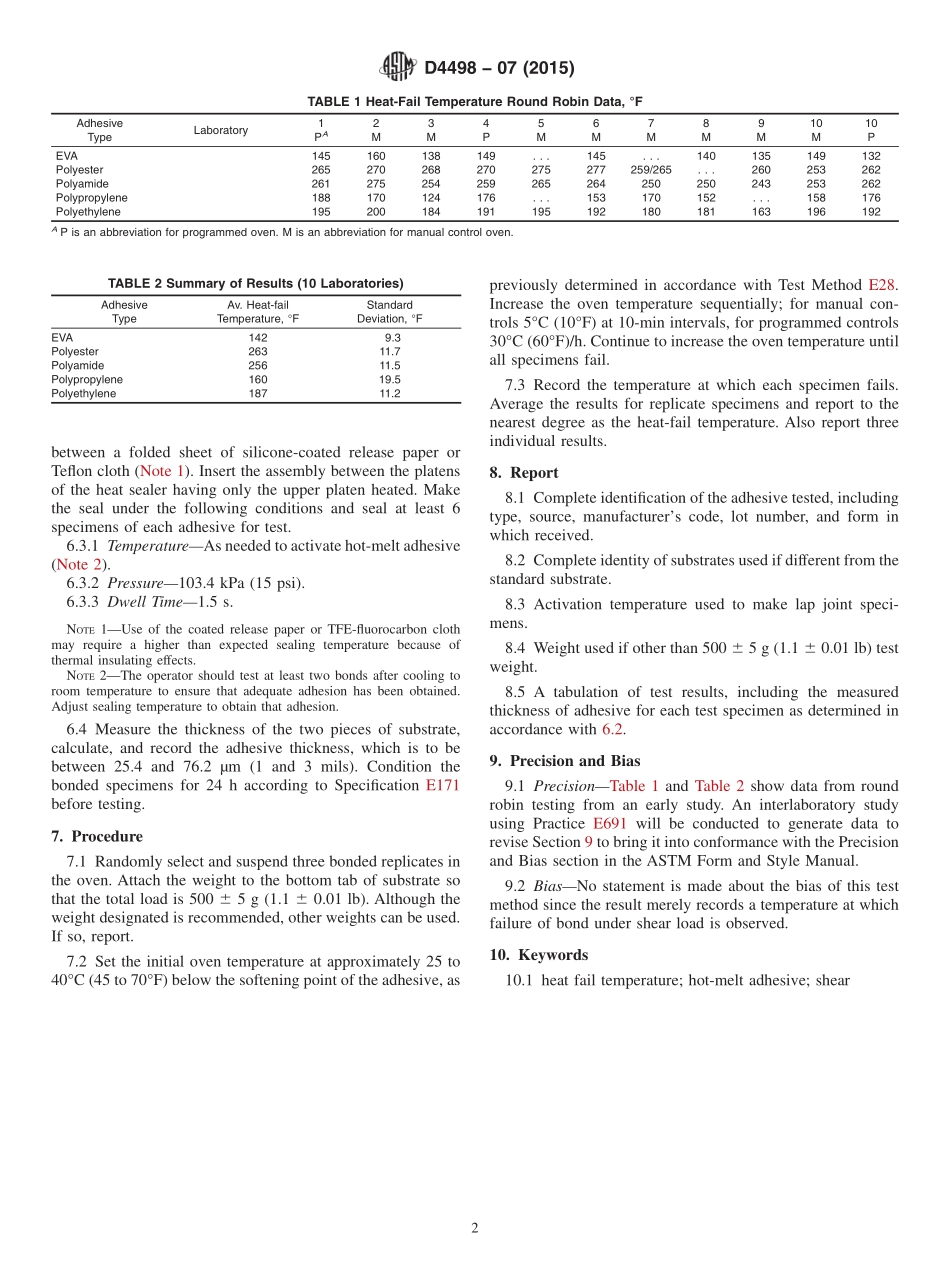

Designation:D4498−07(Reapproved2015)StandardTestMethodforHeat-FailTemperatureinShearofHotMeltAdhesives1ThisstandardisissuedunderthefixeddesignationD4498;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodisintendedtodeterminethetempera-tureatwhichspecimensbondedwithhotmeltadhesivedelaminateunderstaticloadinshear.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D907TerminologyofAdhesivesE28TestMethodsforSofteningPointofResinsDerivedfromPineChemicalsandHydrocarbons,byRing-and-BallApparatusE145SpecificationforGravity-ConvectionandForced-VentilationOvensE171PracticeforConditioningandTestingFlexibleBarrierPackagingE691PracticeforConductinganInterlaboratoryStudytoDeterminethePrecisionofaTestMethod3.Terminology3.1Definitions—ManyofthetermsfoundinthistestmethodaredefinedinTerminologyD907.3.2DefinitionsofTermsSpecifictoThisStandard:3.2.1heat-failtemperature,n—thetemperatureatwhichdelaminationoccursunderstaticloadinginshear.4.SignificanceandUse4.1Heat-failtemperatureestablishesalimitingtemperatureabovewhichtheadhesiveisnottobeexposedinserviceundershearload.5.Apparatus5.1Adevicecapableofproducingadhesivefilmsofuni-formthicknesswith625.4µm(61mil)tolerances.5.2StandardSubstrate—NISTStandardReferenceMaterial1810(Liner-Board)35.3HeatSealingDevice—Sentinelheatsealerorequivalentcapableofmaintainingselectedsealingtemperaturewithin62.5°C(65°F).5.4Forced-VentilationOven,manualorprogrammed.Ovenshallbecapableofmaintainin...