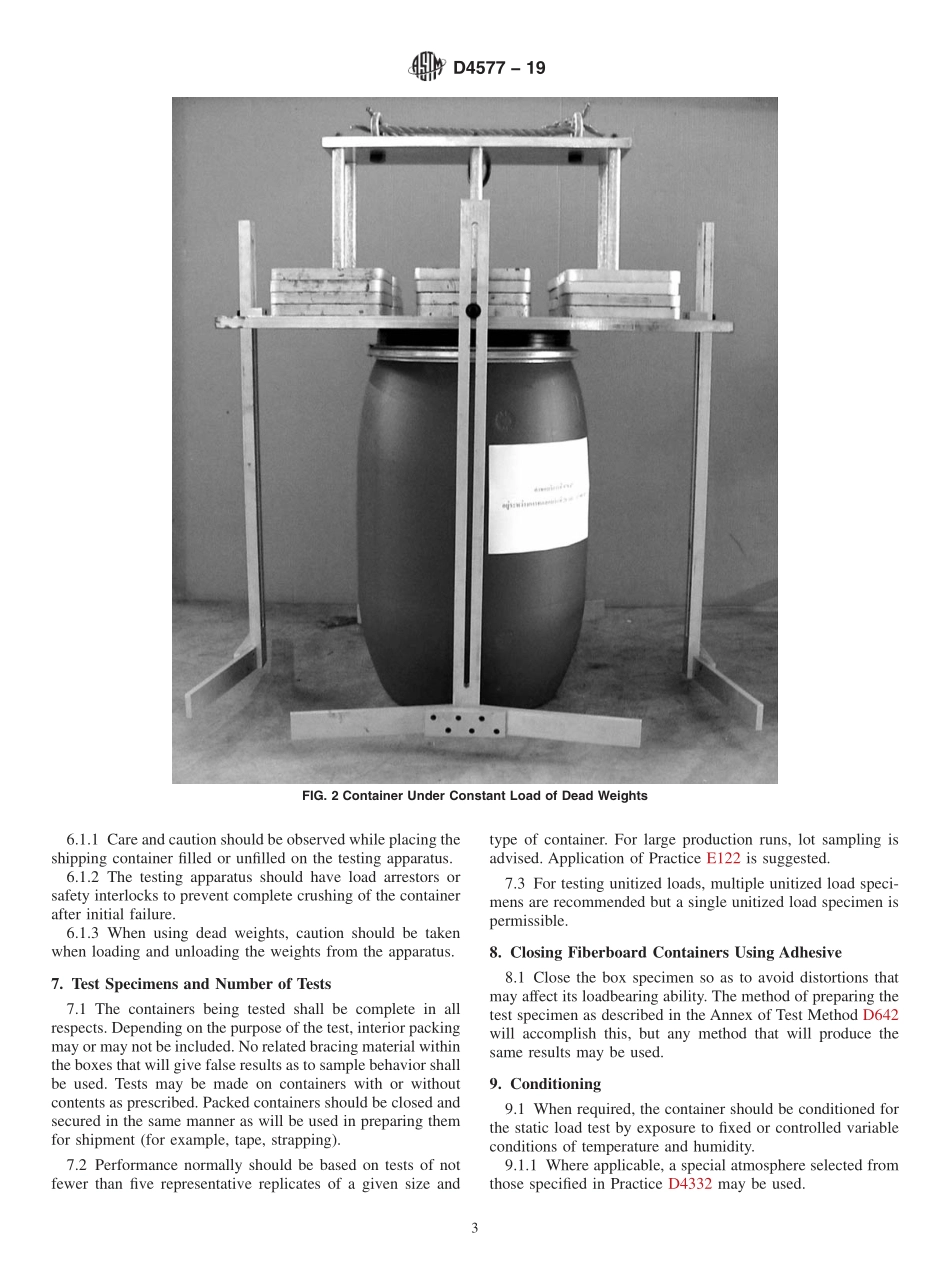

Designation:D4577−19StandardTestMethodforCompressionResistanceofaContainerUnderConstantLoad1ThisstandardisissuedunderthefixeddesignationD4577;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodisdesignedtodeterminetheresistanceofashippingcontainertoaverticallyappliedconstantloadforeitheraspecifiedtimeortofailure.Thetestmethodmayalsobeusedforpalletizedorunitizedloadconfigurations.1.2Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.Forspecificprecautionarystatements,seeSection6.1.3Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D642TestMethodforDeterminingCompressiveResistanceofShippingContainers,Components,andUnitLoadsD685PracticeforConditioningPaperandPaperProductsforTestingD996TerminologyofPackagingandDistributionEnviron-mentsD4332PracticeforConditioningContainers,Packages,orPackagingComponentsforTestingD4442TestMethodsforDirectMoistureContentMeasure-mentofWoodandWood-BasedMaterialsE122PracticeforCalculatingSampleSizetoEstimate,WithSpecifiedPrecision,theAverageforaCharacteristicofaLotorProcess2.2TAPPIStandard3T412Moistureinpulp,paperandpaperboard3.Terminology3.1Definitions—GeneraldefinitionsforthepackaginganddistributionenvironmentsarefoundinTerminologyD996.3.2DefinitionsofTermsSpecifictoThisStandard:3.2.1load—theforceappliedtoabody,lbforN.3.2.2constantload—aloadt...