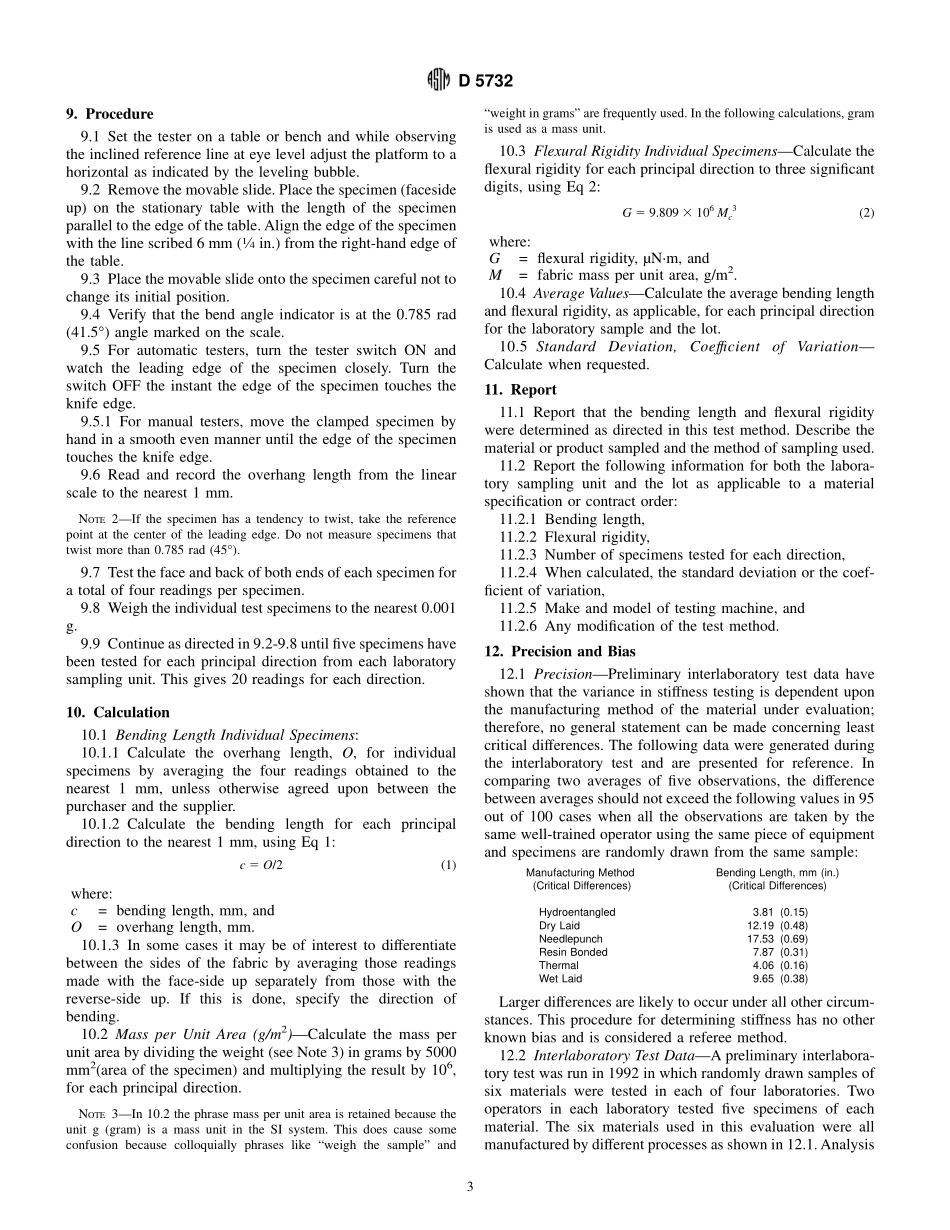

Designation:D5732–95(Reapproved2001)StandardTestMethodforStiffnessofNonwovenFabricsUsingtheCantileverTest1ThisstandardisissuedunderthefixeddesignationD5732;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversstiffnesspropertiesofnon-wovenfabricsbyemployingtheprincipleofcantileverbendingofthefabricunderitsownweight.Bendinglengthismeasuredandflexuralrigiditycalculated.1.2Thistestmethodappliestomostnonwovenfabricsthataretreatedoruntreated,includingthoseheavilysized,coated,orresin-treated.1.3ThevaluesstatedinSIunitsaretoberegardedasthestandard.Theinch-poundunitsgiveninparenthesesmaybeapproximate.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:D123TerminologyRelatingtoTextiles2D1776PracticeforConditioningTextilesforTesting2D2904PracticeforInterlaboratoryTestingofaTextileTestMethodThatProducesNormallyDistributedData23.Terminology3.1Definitions:3.1.1bendinglength,n—intextiles,ameasureoftheinteractionbetweenfabricweightandfabricstiffnessasshownbythewayinwhichafabricbendsunderitsownweight.3.1.1.1Discussion—Bendinglengthreflectsthestiffnessofafabricwhenbentinoneplaneundertheforceofgravityandisonecomponentofdrape.3.1.2cross-machinedirection,CD,n—thedirectionintheplaneofthefabricperpendiculartothedirectionofmanufac-ture.3.1.2.1Discussion—Innonwovenfabrics,thetermcross-machinedirectionisusedtorefertothedirectionanalogoustocrosswiseorfillingdirectioninawovenfabric.3.1.3flexuralrigidity,n—ameasureofstiffness,thecoupleoneitherendofastriporunitwidthbentintounitcurvature,intheabsenceofanytension.3.1.4machinedirection,...