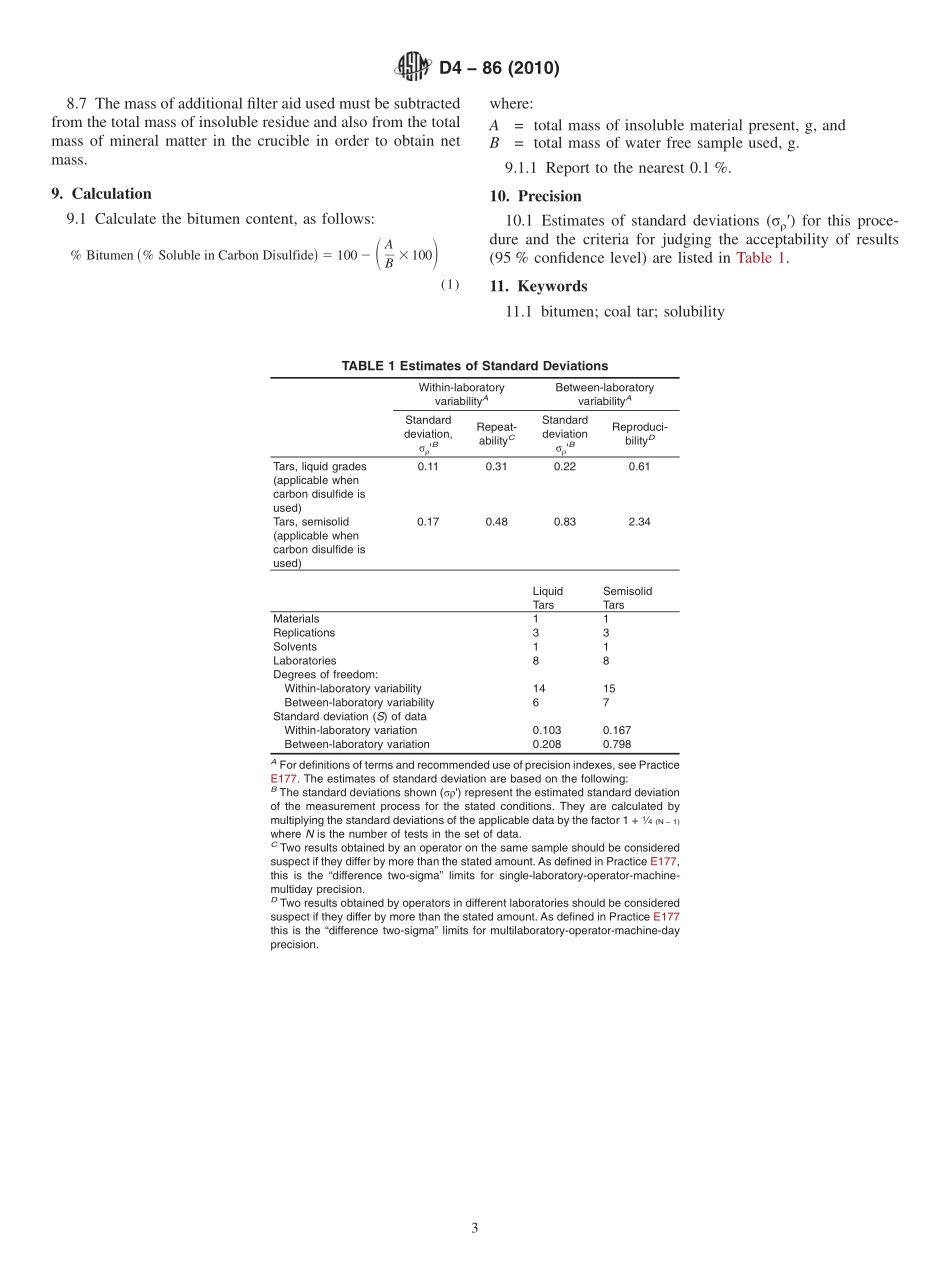

Designation:D4−86(Reapproved2010)StandardTestMethodforBitumenContent1ThisstandardisissuedunderthefixeddesignationD4;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.AlthoughthistestmethodwaswithdrawnbytheSocietyinJune1966attherequestofCommitteeD04,theCommitteeonStandardshasapproveditsreinstatementunderthejurisdictionofCommitteeD08onthebasisthatProcedureNo.2stillappliestotheirinterest.ProcedureNo.1hasbeenreplacedbyMethodD2042,TestforSolubilityofAsphaltMaterialsinTrichloroethylene.1.Scope1.1Thistestmethodcoversthedeterminationofbitumencontentinmaterialscontainingatleast25%bitumen.Bitumencontentmayusuallybeexpeditiouslyandaccuratelydeter-minedbyProcedureNo.1,Section7.However,somebitumi-nousmaterialscontainingfinelydividedmineralmattermayclogthefilterorthemineralresiduemaynotbeeasilyretained,inwhichcasesProcedureNo.2,Section8,shallbefollowed.1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityandregulatorylimitationspriortouse.Forspecificprecautionaryinformation,seeSection4.2.ReferencedDocuments2.1ASTMStandards:2D370PracticeforDehydrationofOil-TypePreservativesE177PracticeforUseoftheTermsPrecisionandBiasinASTMTestMethods3.Apparatus,Reagents,andMaterials3.1FilteringCrucible,porcelain,high-form,25-to40-mLcapacity,withfine-porositybottom,7-µmmaximumporosity.NOTE1—Selasgrade01,sizeFC30orFC40,orequivalent.Availablefromvariouslaboratorysupplyhouses.3.2CeliteAnalyticalFilterAid(CAFA),driedtoconstantmassat105°Candstoredinatightlystopperedcon...