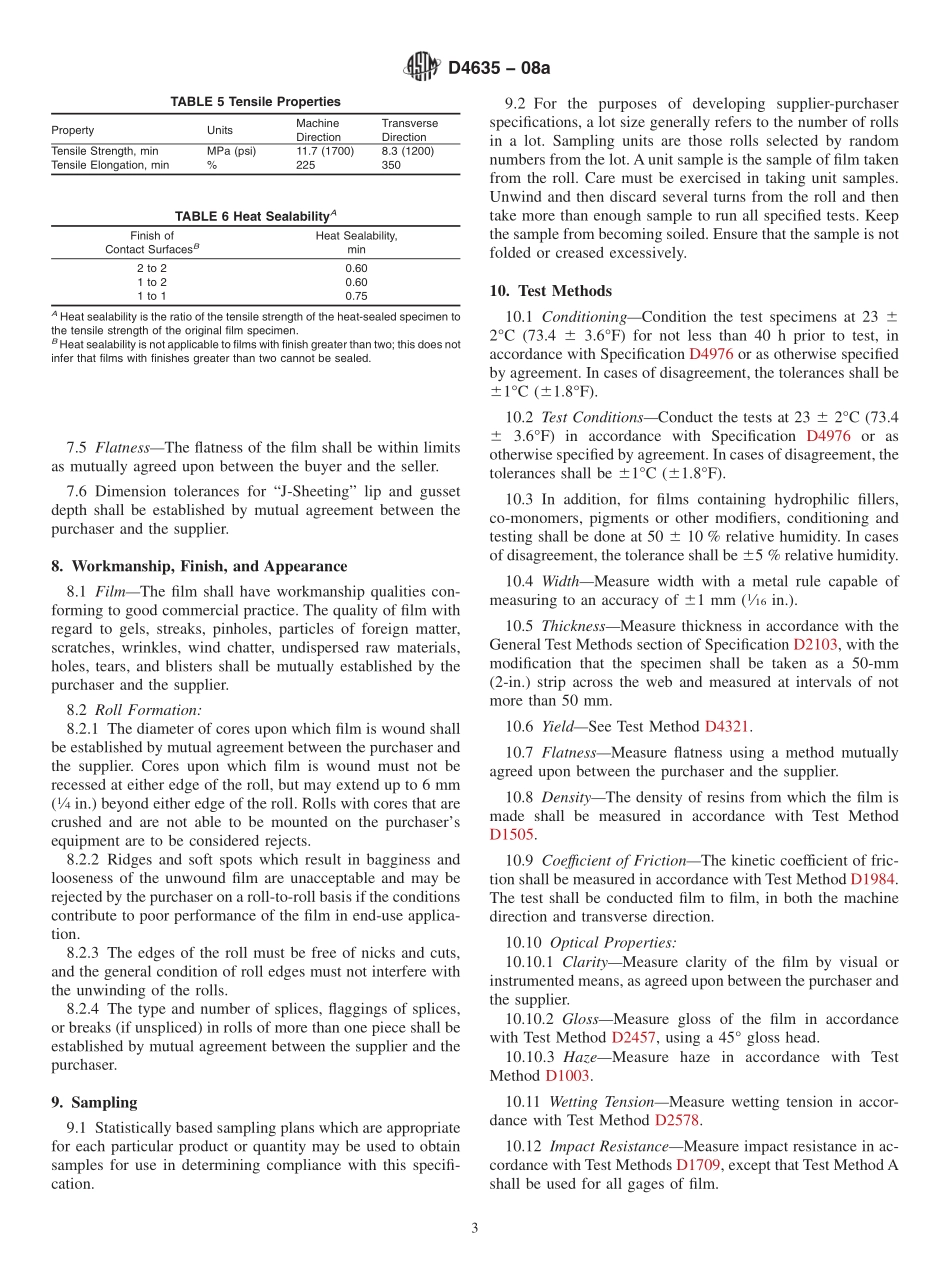

Designation:D4635−08aStandardSpecificationforPolyethyleneFilmsMadefromLow-DensityPolyethyleneforGeneralUseandPackagingApplications1ThisstandardisissuedunderthefixeddesignationD4635;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thisspecificationcoversunpigmented,unsupported,low-densitypolyethylenefilms(hereafterreferredtoasfilmorfilms)fromClass1polyethylenesperSpecificationD4976.NOTE1—Thedensityofafilmwillnotnecessarilybeequaltothedensityofamoldedplaquefromthesameresin.NOTE2—Blendsofethylene/vinylacetate(EVA)withlow-densitypolyethylenemayhavedensitiesupto0.929g/cm3.1.2Thisspecificationisapplicabletohomopolymerpolyethylene,butisnotrestrictedtoit.Itisapplicabletofilmsmadefrompolyethylenecopolymers,andalsoapplicabletofilmsmadefromblendsofhomopolymersandcopolymers,includingethylene/vinylacetatecopolymers.1.3Thethicknessofthefilmscoveredbythisspecificationis100µmorless(0.004in.orless),inclusive.Themaximumwidthofthesheetorlayflatis3.00m(120in.).1.4Thisspecificationdoesnotcoverorientedheat-shrinkablefilms.1.5Thisspecificationallowsfortheuseofrecycledpoly-ethylenefilmorresinasfeedstock,inwholeorinpart,aslongasalloftherequirementsofthisspecificationaremetandaslongasanyspecificrequirementsasgovernedbytheproducerandenduserarealsomet.(SeeNote3.)NOTE3—GuideD7209describesterminologyanddefinitionsrelatedtorecycledplastics.1.6Thisspecificationdefinesthelevelsofthevariousphysicalpropertiesfromwhichspecificationsforspecificfilmsmaybedescribed.ThelevelsofphysicalpropertiesrequiredbyafilmforagivenapplicationareselectedfromSection6.However,Sections2-5relatingtotolerancesshallapplywithoutchangetoallfilmfallingwithinthescopeindicatedbythetitleand1.1-1.4.1.7Thisspecificationcoversdimensionaltolerances,classifications,intrinsicqualityrequirements,andtestmethods.Thed...