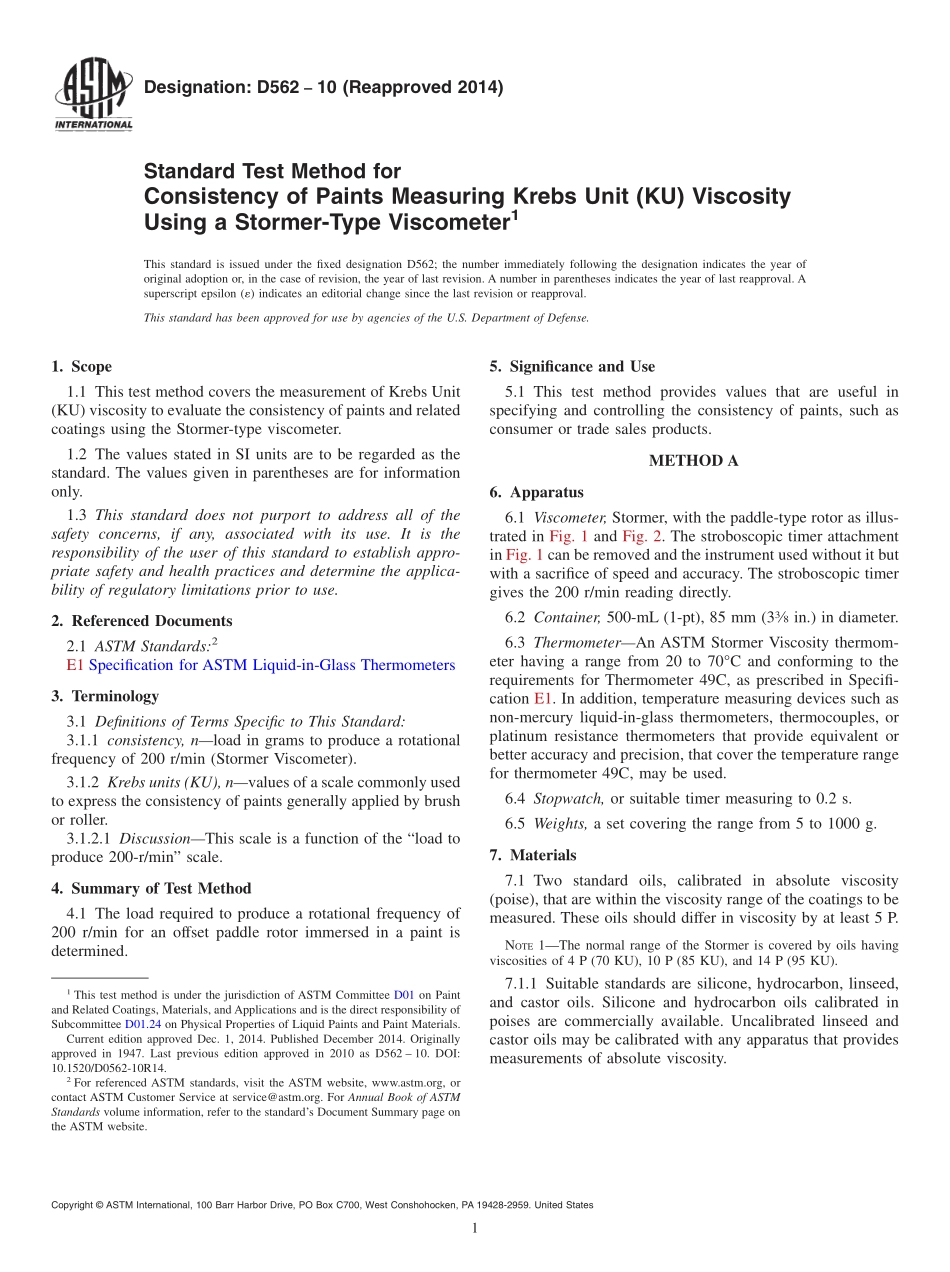

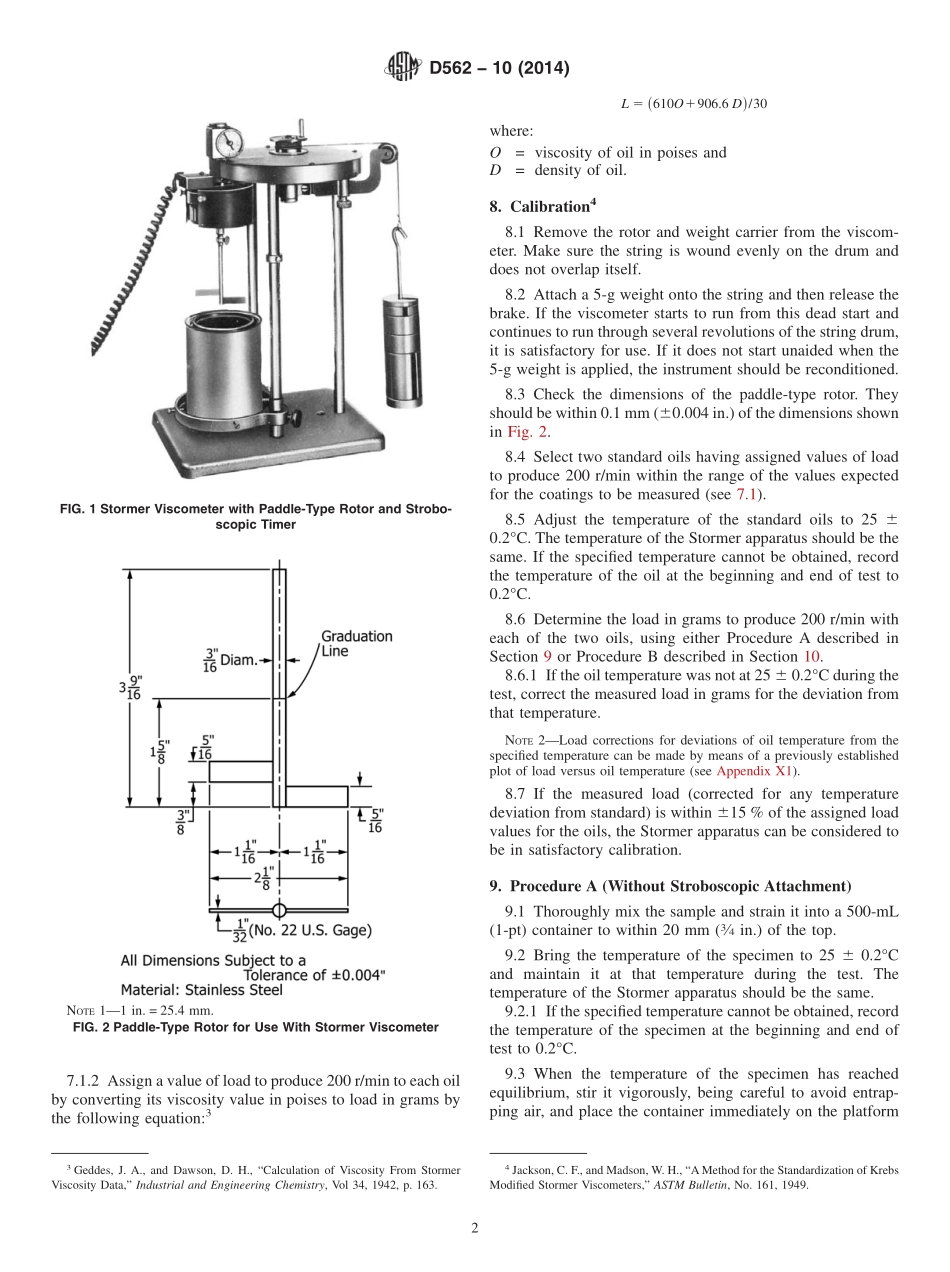

Designation:D562−10(Reapproved2014)StandardTestMethodforConsistencyofPaintsMeasuringKrebsUnit(KU)ViscosityUsingaStormer-TypeViscometer1ThisstandardisissuedunderthefixeddesignationD562;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope1.1ThistestmethodcoversthemeasurementofKrebsUnit(KU)viscositytoevaluatetheconsistencyofpaintsandrelatedcoatingsusingtheStormer-typeviscometer.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2E1SpecificationforASTMLiquid-in-GlassThermometers3.Terminology3.1DefinitionsofTermsSpecifictoThisStandard:3.1.1consistency,n—loadingramstoproducearotationalfrequencyof200r/min(StormerViscometer).3.1.2Krebsunits(KU),n—valuesofascalecommonlyusedtoexpresstheconsistencyofpaintsgenerallyappliedbybrushorroller.3.1.2.1Discussion—Thisscaleisafunctionofthe“loadtoproduce200-r/min”scale.4.SummaryofTestMethod4.1Theloadrequiredtoproducearotationalfrequencyof200r/minforanoffsetpaddlerotorimmersedinapaintisdetermined.5.SignificanceandUse5.1Thistestmethodprovidesvaluesthatareusefulinspecifyingandcontrollingtheconsistencyofpaints,suchasconsumerortradesalesproducts.METHODA6.Apparatus6.1Viscometer,Stormer,withthepaddle-typerotorasillus-tratedinFig.1andFig.2.ThestroboscopictimerattachmentinFig.1canberemovedandtheinstrumentusedwithoutitbutwithasacrificeofspeedandaccuracy.Thestroboscopictimergivesthe200r/minreadingdirectly.6.2Container,500-mL(1-pt),85...