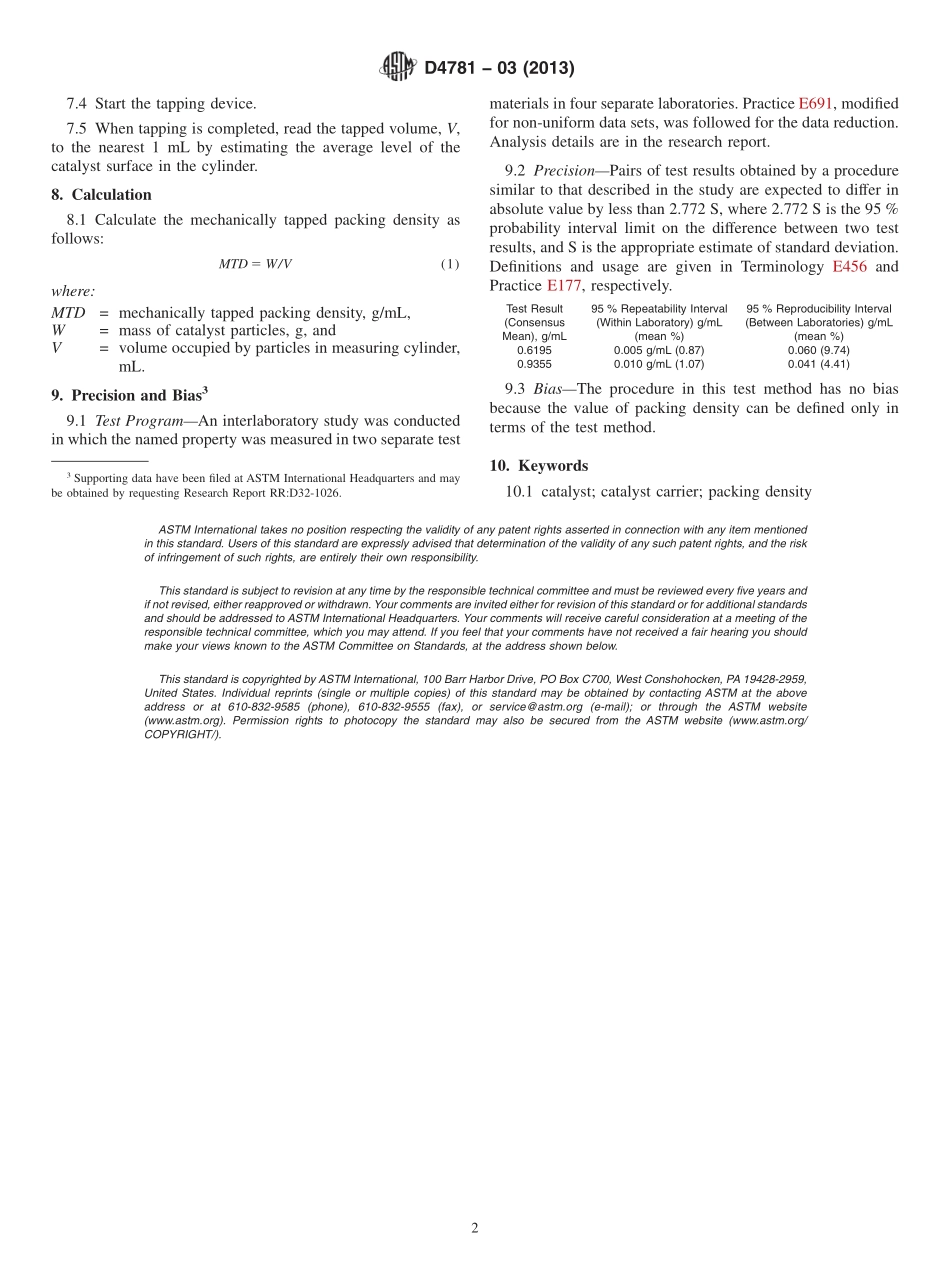

Designation:D4781−03(Reapproved2013)StandardTestMethodforMechanicallyTappedPackingDensityofFineCatalystParticlesandCatalystCarrierParticles1ThisstandardisissuedunderthefixeddesignationD4781;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthedeterminationoftheme-chanicallytappedpackingdensityoffinecatalystandcatalystcarrierparticlessmallerthan0.8mmindiameter.1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifanyassociatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D3766TerminologyRelatingtoCatalystsandCatalysisE177PracticeforUseoftheTermsPrecisionandBiasinASTMTestMethodsE456TerminologyRelatingtoQualityandStatisticsE691PracticeforConductinganInterlaboratoryStudytoDeterminethePrecisionofaTestMethod3.Terminology3.1Definitions—SeeTerminologyD3766.4.SummaryofTestMethod4.1Apreconditionedsampleofdriedfinecatalystorcata-lystcarrierparticlesistappedinagraduatedcylinder.Themechanicallytappedpackingdensityisdeterminedfromtheknownmassandtappedvolume.5.SignificanceandUse5.1Thistestmethodisformeasuringthemechanicallytappedpackingdensityofpowdersthataresmallerthan0.8mmindiameter,suchasFluidizedCatalyticCrackingCatalysts(FCC).6.Apparatus6.1GraduatedCylinder,capacity100mL.6.2Holder,acylinderholderweighing454g.6.3TappingDevice,consistingofabaseplatewithwormdrive,withspecificationsof250r/mincamshaftspeed,tappingstroketravelof3.2mm.6.4Counter,afour-digitadjustablecounter,whichcanbepresettodelivernumberoftapsbetween1and9999.6.5Desiccator,withadesiccantgrademolecularsievesuchas4...