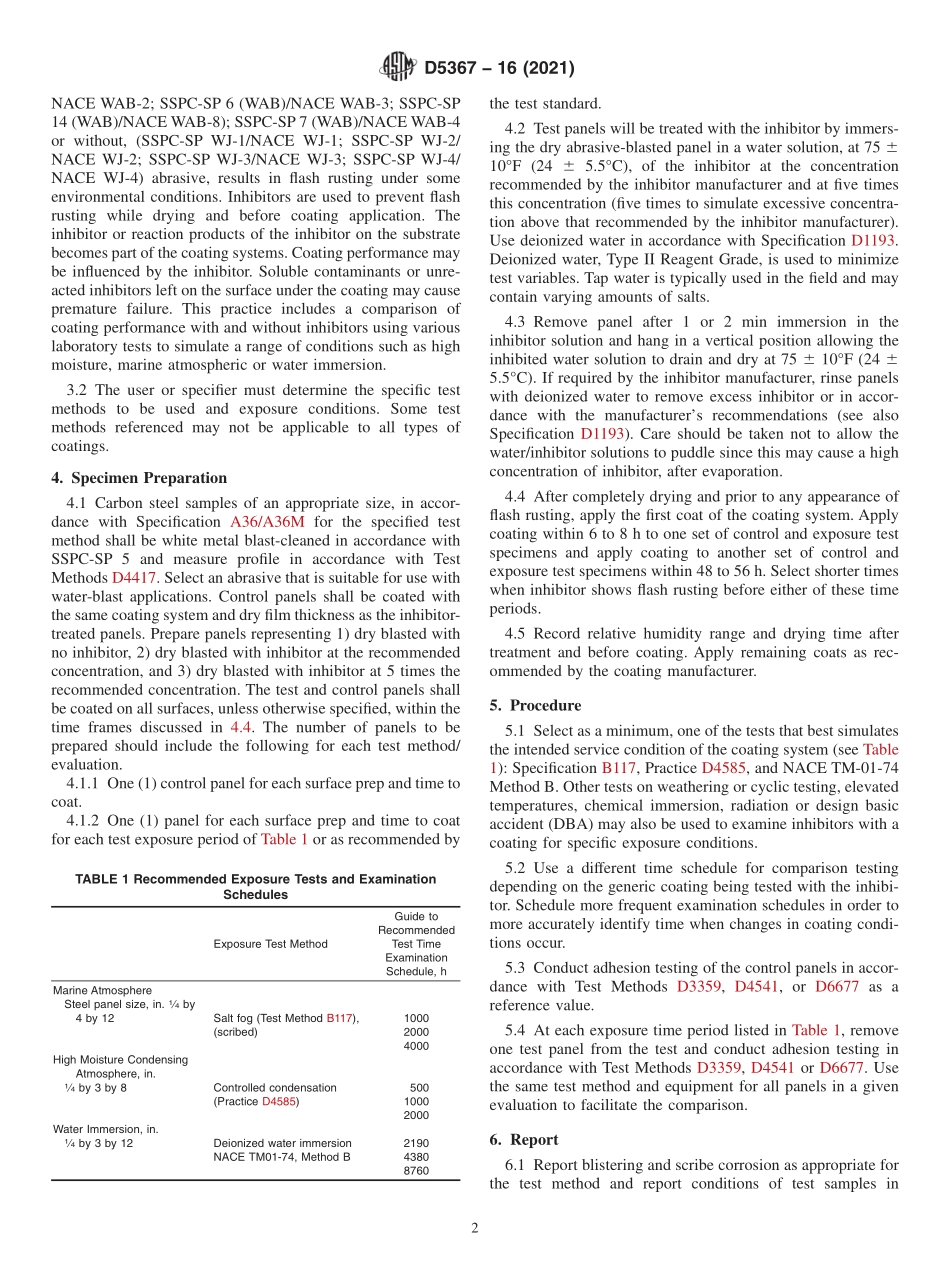

Designation:D5367−16(Reapproved2021)StandardPracticeforEvaluatingCoatingsAppliedOverSurfacesTreatedWithInhibitorsUsedtoPreventFlashRustingofSteelWhenWaterorWater/AbrasiveBlasted1ThisstandardisissuedunderthefixeddesignationD5367;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thispracticecoversprocedurestoevaluatethecompat-ibilityofcoatingswithinhibitorsusedtopreventflashrustingofsteelbeforeapplicationofcoatings.1.2Theinhibitorsareusedwithwater-blastcleaningsurfacepreparationandmaybeusedwithorwithoutabrasives.1.3Themanufacturerofthecoatingsshallbeconsultedtoensurecompatibilityofinhibitorswiththecoatings.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.1.5Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2A36/A36MSpecificationforCarbonStructuralSteelB117PracticeforOperatingSaltSpray(Fog)ApparatusD714TestMethodforEvaluatingDegreeofBlisteringofPaintsD1193SpecificationforReagentWaterD1654TestMethodforEvaluationofPaintedorCoatedSpecimensSubjectedtoCorrosiveEnvironmentsD3359TestMethodsforRatingAdhesionbyTapeTestD4417TestMethodsforFieldMeasurementofSurfaceProfileofBlastCleanedSteelD4541TestMethodforPull-OffStrengthofCoatingsUsingPortableAdhesionTestersD4585PracticeforTestingWaterResistanceofCoatingsUsingControlledCondensationD6677TestMethodforEvaluatingAdhesionbyKnife2.2SSPCDocuments:3S...