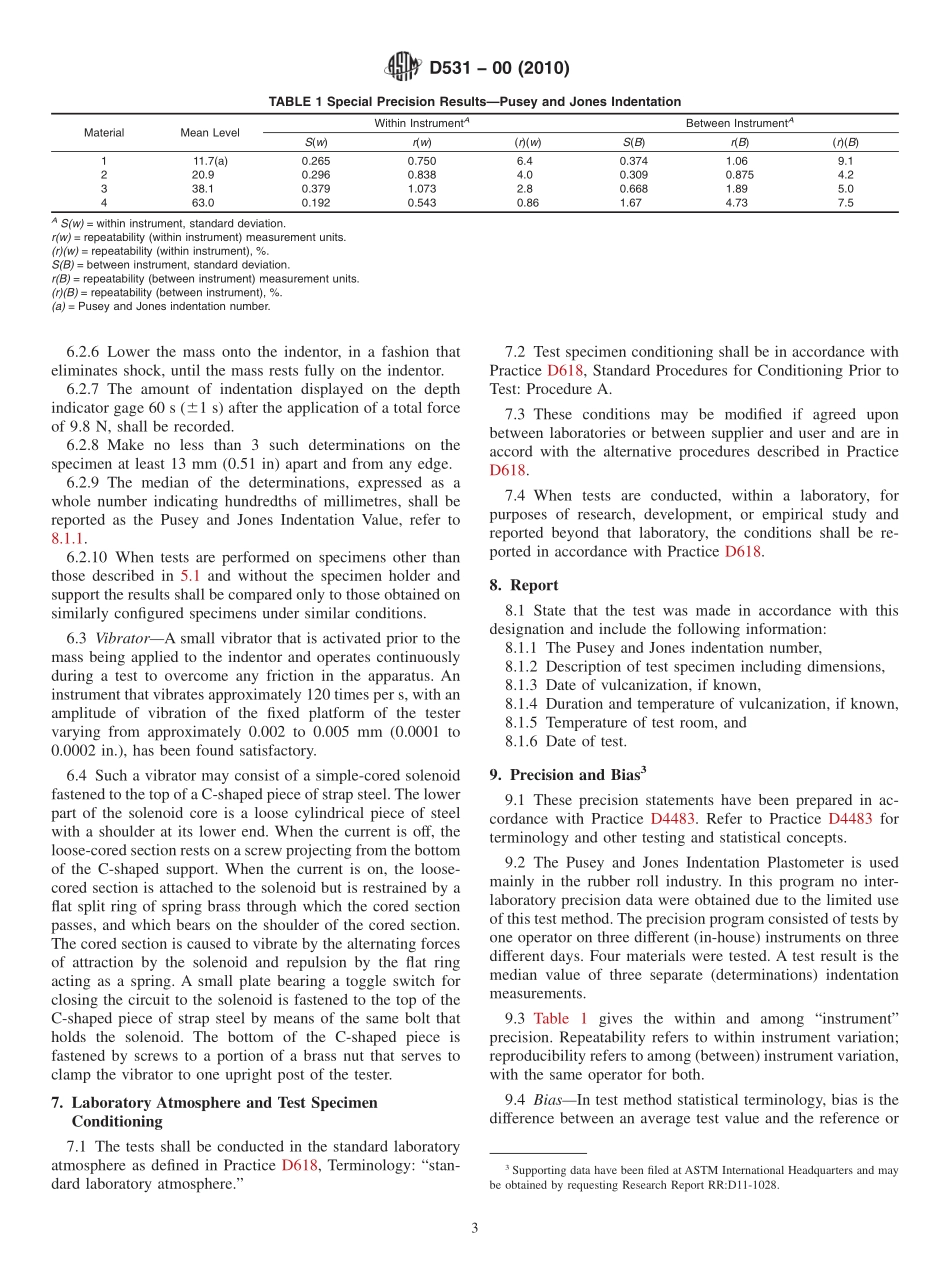

Designation:D531−00(Reapproved2010)StandardTestMethodforRubberProperty—PuseyandJonesIndentation1ThisstandardisissuedunderthefixeddesignationD531;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheDepartmentofDefense.1.Scope1.1Thistestmethodcoversthedeterminationoftheinden-tationofrubberorrubber-likematerialsbymeansofthePuseyandJonestypeofplastometer.Thisapparatusisusedtomeasurethedepthofindentationofanindentor,underfixedforceintothesurfaceofaspecimen.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D618PracticeforConditioningPlasticsforTestingD1415TestMethodforRubberProperty—InternationalHardnessD4483PracticeforEvaluatingPrecisionforTestMethodStandardsintheRubberandCarbonBlackManufacturingIndustriesNOTE1—ThespecificdatededitionofthepracticethatprevailsinthisdocumentisreferencedintheSection9.3.SignificanceandUse3.1ThePuseyandJonesindentationvalueisthedepthofindentation,expressedinhundredthsofamillimetre,ofaball3.175mm(0.1250in.)indiameterunderanexpressedforceof9.8N(2.2lbf).Thisvaluemaybeusedtocomparetheindentationresistanceofrubberandrubber-likematerials.3.2TheindentationvalueobtainedshouldnotbeconfusedwithhardnessasmeasuredbyTestMethodD1415,sinceinthelattertesttherubberimmediatelyadjacenttotheindentorisprecompressed.4.Apparatus4.1Plastometer,aninstrumentconsistingofanindentor,amassforapplyingthestatedforceontheindentor,amicrom-eterforindicatingthedepthoftheindentation,aspecimenholderandsupport.4.1.1Indentor,forindentingthespeci...