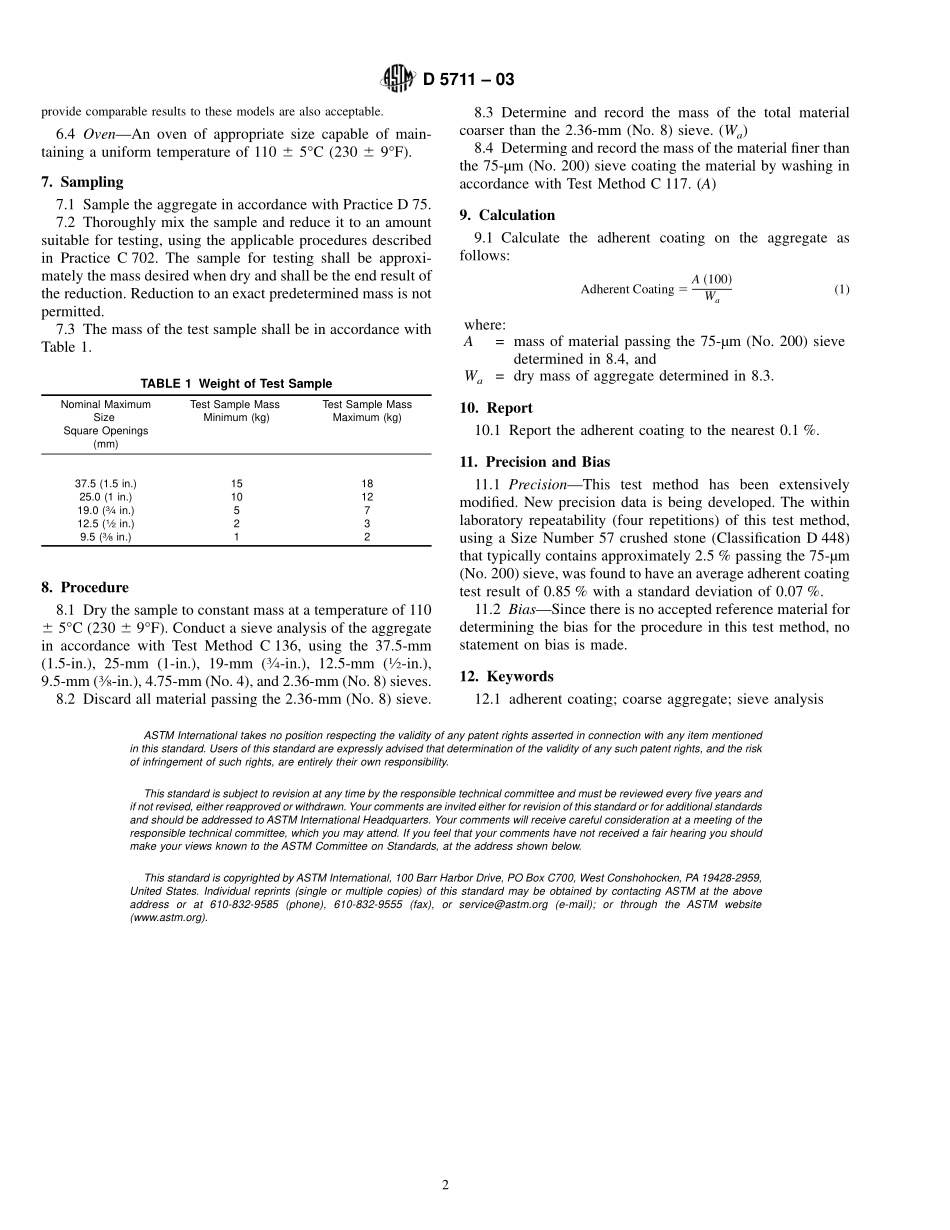

Designation:D5711–03StandardTestMethodforDeterminingtheAdherentCoatingonCoarseAggregates1ThisstandardisissuedunderthefixeddesignationD5711;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodisusedtodeterminetheadherentcoatingoncoarseaggregate(aggregateretainedonthe2.36-mm(No.8)sieve)forthefollowingpurposes:1.1.1Preliminaryinvestigationofmineralaggregatesources.1.1.2Controlofmineralaggregatesusedinhotmixasphalt(HMA)pavements,sealcoats,covercoats,surfacetreatments,coldmixasphalt,andportlandcementconcreteatthesourceofsupply.1.1.3Controlofmineralaggregateprocessingrequirements.1.1.4Acceptanceorrejectionofaggregatesbasedonadher-entcoating.1.2ThevaluesshowninSIunitsaretoberegardedasthestandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.NOTE1—ThistestmethodismodeledafterFederalLandHighwaysT512-94.2.ReferencedDocuments2.1ASTMStandards:C117TestMethodforMaterialFinerthan75-µm(No.200)SieveinMineralAggregatesbyWashing2C136TestMethodforSieveAnalysisofFineandCoarseAggregates2C702PracticeforReducingSamplesofAggregatetoTestingSize2D75PracticeforSamplingAggregates3D448ClassificationforSizesofAggregateforRoadandBridgeConstruction3E11SpecificationforWire-ClothSievesforTestingPur-poses43.Terminology3.1Definitions:3.1.1adherentcoating,n—fineparticlessmallerthan75-µm(No.200)thatstick(adhere)tothecoarseaggregateparticles.3.1.2coarseaggregate,n—aggregatepredominatelyre-tainedonthe2.36-mm(No.8)sieve.4.SummaryofTestMethod4.1Asampleofdryaggregateisseparatedonthe2.36-mm(No.8)sieve.Themassofthematerialcoarserthanthe2.36-mm(No.8)sieveisdeterminedandthematerialiswashe...