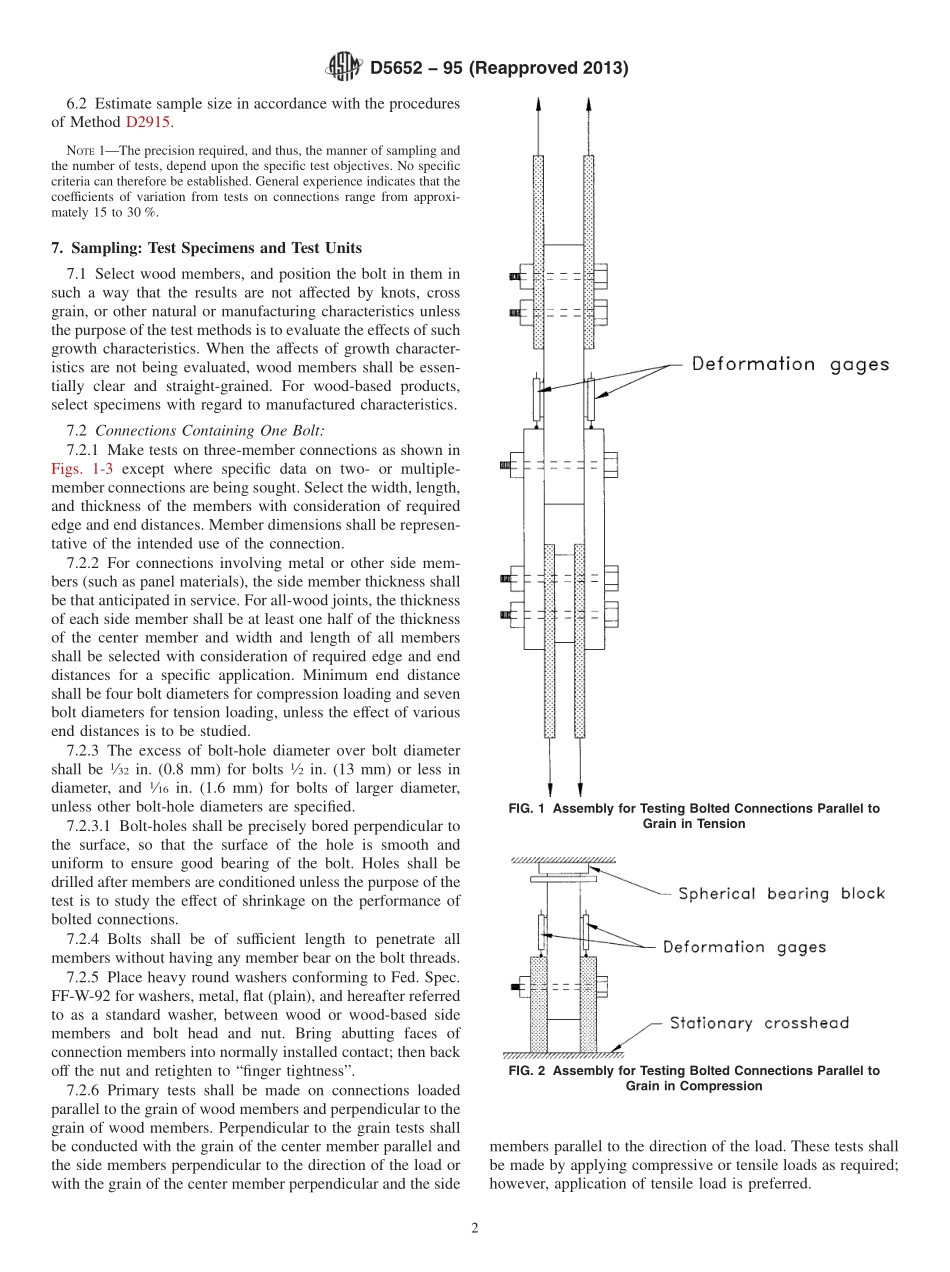

Designation:D5652−95(Reapproved2013)StandardTestMethodsforBoltedConnectionsinWoodandWood-BasedProducts1ThisstandardisissuedunderthefixeddesignationD5652;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thesetestmethodscoverproceduresforevaluatingthestrengthandstiffnessofsingle-boltedconnectionsinwoodorwood-basedproductswhensubjectedtostaticloading.Thesetestmethodsserveasabasisfordeterminingtheeffectsofvariousfactorsonthestrengthandstiffnessoftheconnection.1.2Thevaluesstatedininch-poundunitsaretoberegardedasthestandard.TheSIunitsinparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D2395TestMethodsforSpecificGravityofWoodandWood-BasedMaterialsD2915PracticeforSamplingandData-AnalysisforStruc-turalWoodandWood-BasedProductsD4442TestMethodsforDirectMoistureContentMeasure-mentofWoodandWood-BaseMaterialsE4PracticesforForceVerificationofTestingMachinesF606TestMethodsforDeterminingtheMechanicalProper-tiesofExternallyandInternallyThreadedFasteners,Washers,DirectTensionIndicators,andRivets2.2FederalSpecification:3Fed.Spec.FF-W-92forWashers,Metal,Flat(Plain)3.SummaryofTestMethods3.1Specimensconsistingofatleastonewoodorwood-basedmemberfastenedwithonebolttoatleastoneothermemberofanymaterialareevaluatedforcapacitytoresistcompressiveortensileforcesappliedataconstantrateofdeformationwithasuitabletestingmachine.Thedeformationoftheconnectionatvariousintervalsofloadingismeasured.Supplementaryphysicalpropertiesofthewoodorwood-basedmembersarealsodetermined.4.SignificanceandUse4.1Connectionsareoneoftheweakestlinks...