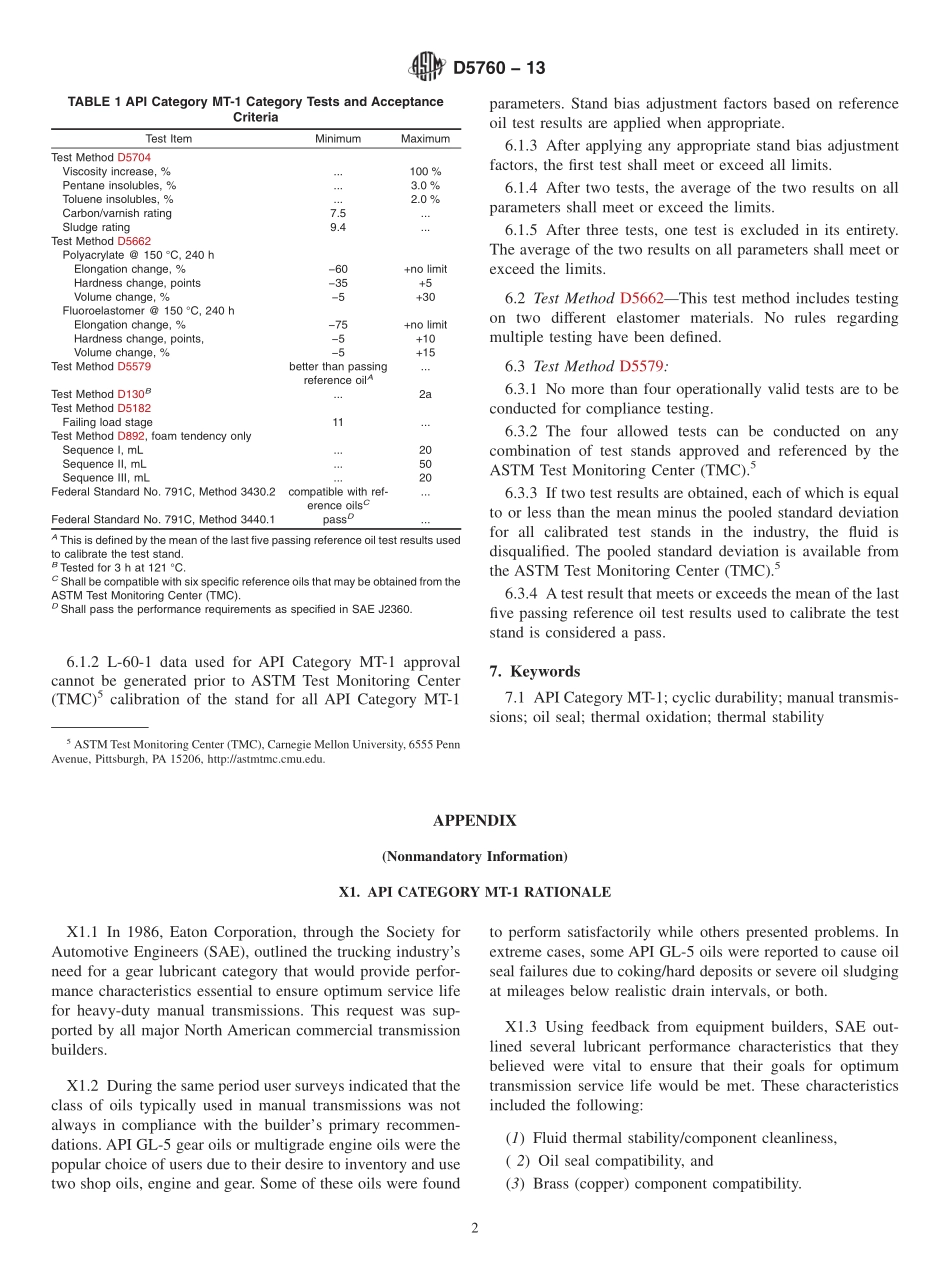

Designation:D5760−13StandardSpecificationforPerformanceofManualTransmissionGearLubricants1ThisstandardisissuedunderthefixeddesignationD5760;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thisspecificationliststhetestmethodsandacceptancecriteriafordeterminingtheacceptabilityoflubricantsusedinnonsynchronizedheavydutymanualtransmissions.1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.2.ReferencedDocuments2.1ASTMStandards:2D130TestMethodforCorrosivenesstoCopperfromPetro-leumProductsbyCopperStripTestD892TestMethodforFoamingCharacteristicsofLubricat-ingOilsD5182TestMethodforEvaluatingtheScuffingLoadCa-pacityofOils(FZGVisualMethod)D5579TestMethodforEvaluatingtheThermalStabilityofManualTransmissionLubricantsinaCyclicDurabilityTestD5662TestMethodforDeterminingAutomotiveGearOilCompatibilitywithTypicalOilSealElastomersD5704TestMethodforEvaluationoftheThermalandOxidativeStabilityofLubricatingOilsUsedforManualTransmissionsandFinalDriveAxles2.2FederalStandards:3FederalStandardNo.791C,Method3430.2CompatibilityCharacteristicsofUniversalGearLubricantsFederalStandardNo.791C,Method3440.1StorageSolu-bilityCharacteristicsofUniversalGearLubricants2.3SAEPublications:4SAEJ2360LubricatingOil,GearMultipurpose(Metric)MilitaryUse3.Terminology3.1DefinitionsofTermsSpecifictoThisStandard:3.1.1nonsynchronizedtransmission,n—atransmissionhav-ingnomeansforsynchronizingthespeedsofengagingelements.Typicalheavy-dutymanualtransmissionshavenosuchmeansforgearengagementbytheshiftlever,butmayhavesuchmeansforpneumaticengagementofauxiliaryrangegears.3.1.2oilsealcompatibility,n—inlubricantsforlubricatingmanualtransmissionsandfinaldriveaxles,preventionofchemicalorthermaldegradationofsealelastomerstypicallyobservedashardening,cracking,...