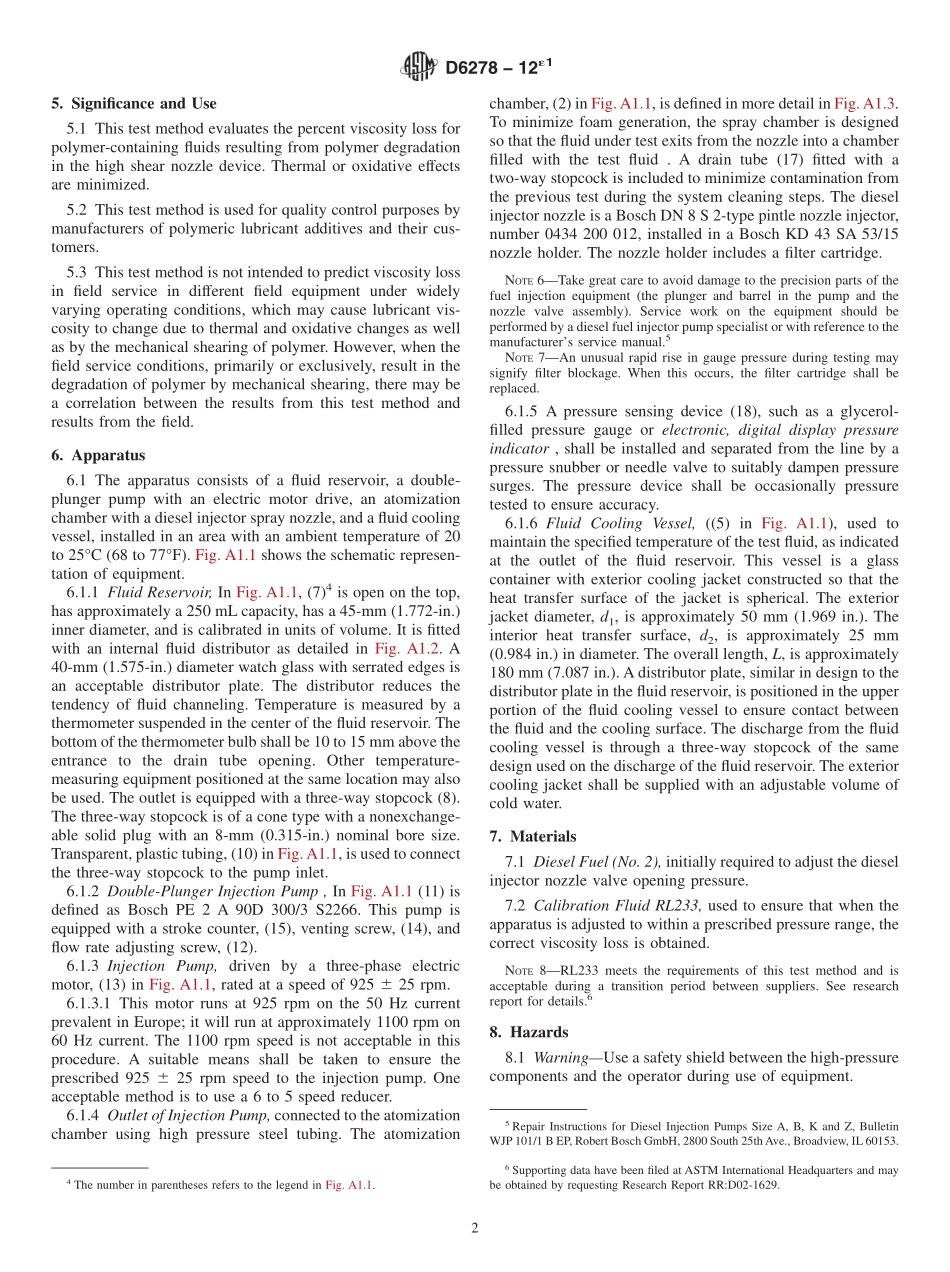

Designation:D6278−12´1StandardTestMethodforShearStabilityofPolymerContainingFluidsUsingaEuropeanDieselInjectorApparatus1ThisstandardisissuedunderthefixeddesignationD6278;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ε1NOTE—Editorialchangesmadeto3.2.1andSection10inApril2013.1.Scope*1.1Thistestmethodcoverstheevaluationoftheshearstabilityofpolymer-containingfluids.Thetestmethodmea-suresthepercentviscositylossat100°Cofpolymer-containingfluidswhenevaluatedbyadieselinjectorapparatusprocedurethatusesEuropeandieselinjectortestequipment.Theviscositylossreflectspolymerdegradationduetoshearatthenozzle.NOTE1—TestMethodD2603hasbeenusedforsimilarevaluationofshearstability;limitationsareasindicatedinthesignificancestatement.Nodetailedattempthasbeenundertakentocorrelatetheresultsofthistestmethodwiththoseofthesonicsheartestmethod.NOTE2—ThistestmethodusestestapparatusasdefinedinCECL-14-A-93.ThistestmethoddiffersfromCEC-L-14-A-93intheperiodoftimerequiredforcalibration.NOTE3—TestMethodD5275alsoshearsoilsinadieselinjectorapparatusbutmaygivedifferentresults.NOTE4—ThistestmethodhasdifferentcalibrationandoperationalrequirementsthanwithdrawnTestMethodD3945.NOTE5—TestMethodD7109isasimilarprocedurethatmeasuresshearstabilityatboth30and90injectioncycles.Thistestmethoduses30injectioncyclesonly.1.2Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.Specificprecau-tionarystatementsaregiveninSection8.2.ReferencedDocuments2.1ASTMStandards:2D445TestMethodforKinematicViscosityofTransparentandOpaqueLiquids(andCalculationofDynamicViscos-ity)D2603TestMethodforSonicShearStabilityofPolymer-ContainingOil...