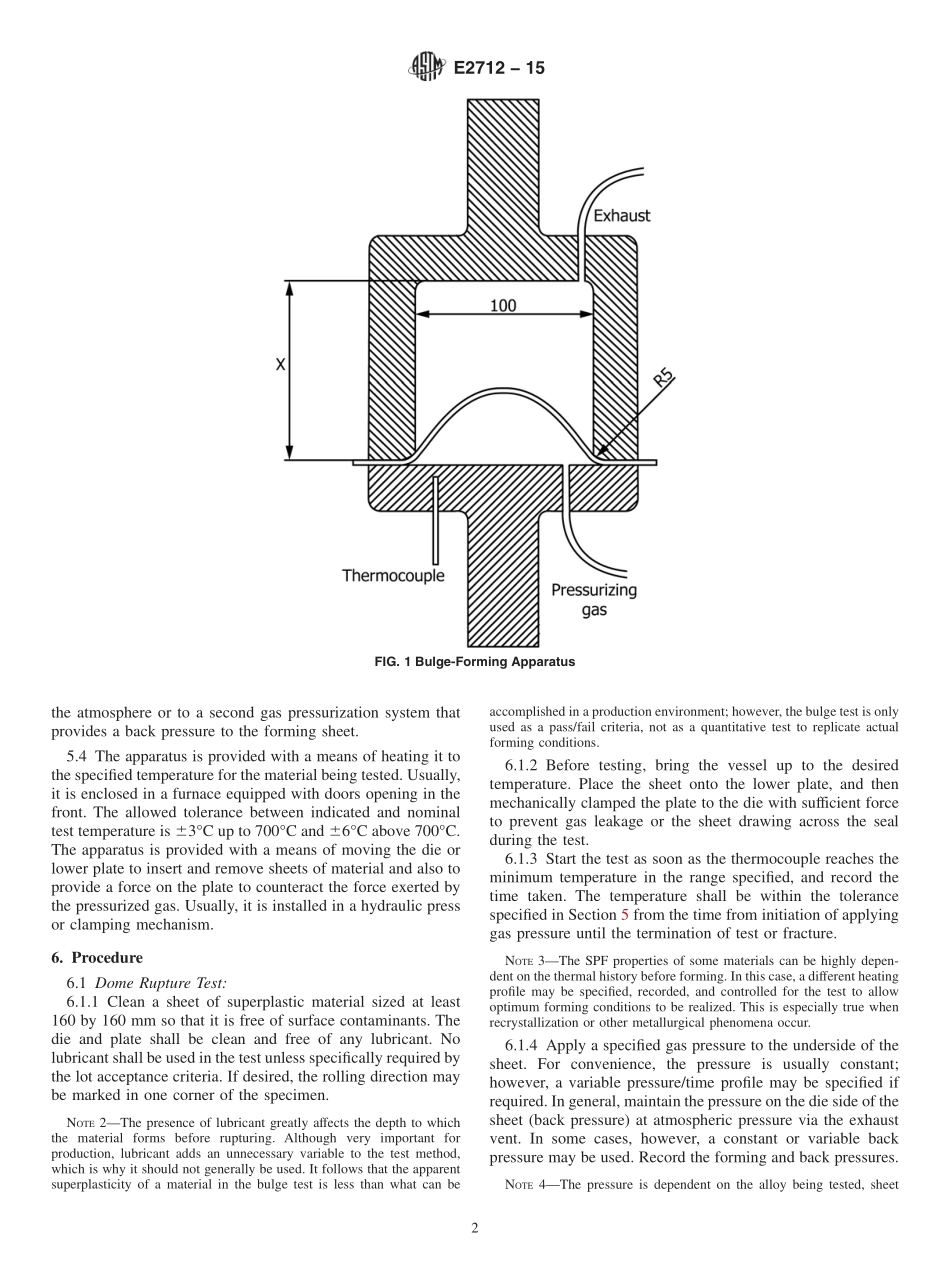

Designation:E2712−15StandardTestMethodsforBulge-FormingSuperplasticMetallicSheet1ThisstandardisissuedunderthefixeddesignationE2712;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thesetestmethodsdescribeproceduresfordeterminingthebiaxialformabilityofasuperplasticmetallicsheetinacirculardie.1.2Theintentofthesetestmethodsareprimarilytobeusedastestsofsuperplasticityasmeasuredbytheabilitytoformtoaprescribeddepthinadiecavitywithoutrupturing.Thesetestmethodscanalsobeusedtogeneratematerialforthemeasure-mentofcavitationintheformedpart.Thesecanbeusedasgo/nogocriteriaforqualificationtoaspecification.1.3Thesetestmethodshavebeenusedsuccessfullywithaluminumalloys.Theuseofthesetestmethodsonothermetalsshouldbeverified.1.4ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.5Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2E2448TestMethodforDeterminingtheSuperplasticProp-ertiesofMetallicSheetMaterials3.SummaryofTestMethod3.1Twomethodsofbulgeformingareincludedinthesetestmethods.3.1.1Inthefirsttestmethod,thesheetisformedintoadieofafixeddepthasprescribedinaspecification.Ifittouchesthebaseofthediewithoutrupturing,thenitisconsideredtohavemetthespecification.3.1.2Inthesecondtestmethod,thedepthofthedieisreducedsothatthematerialfillsthedie.Aportionexcisedfromthecenteroftheformedpartmaybeexaminedforinternalcavitationwithinthesheet.4.SignificanceandUse4.1Whenasuperplasticmaterialisregularlybeingusedinindustrialproduction,itisoftenconvenienttousethebulgetesttoqualifyabatchorheatlottoanacceptancecrite...