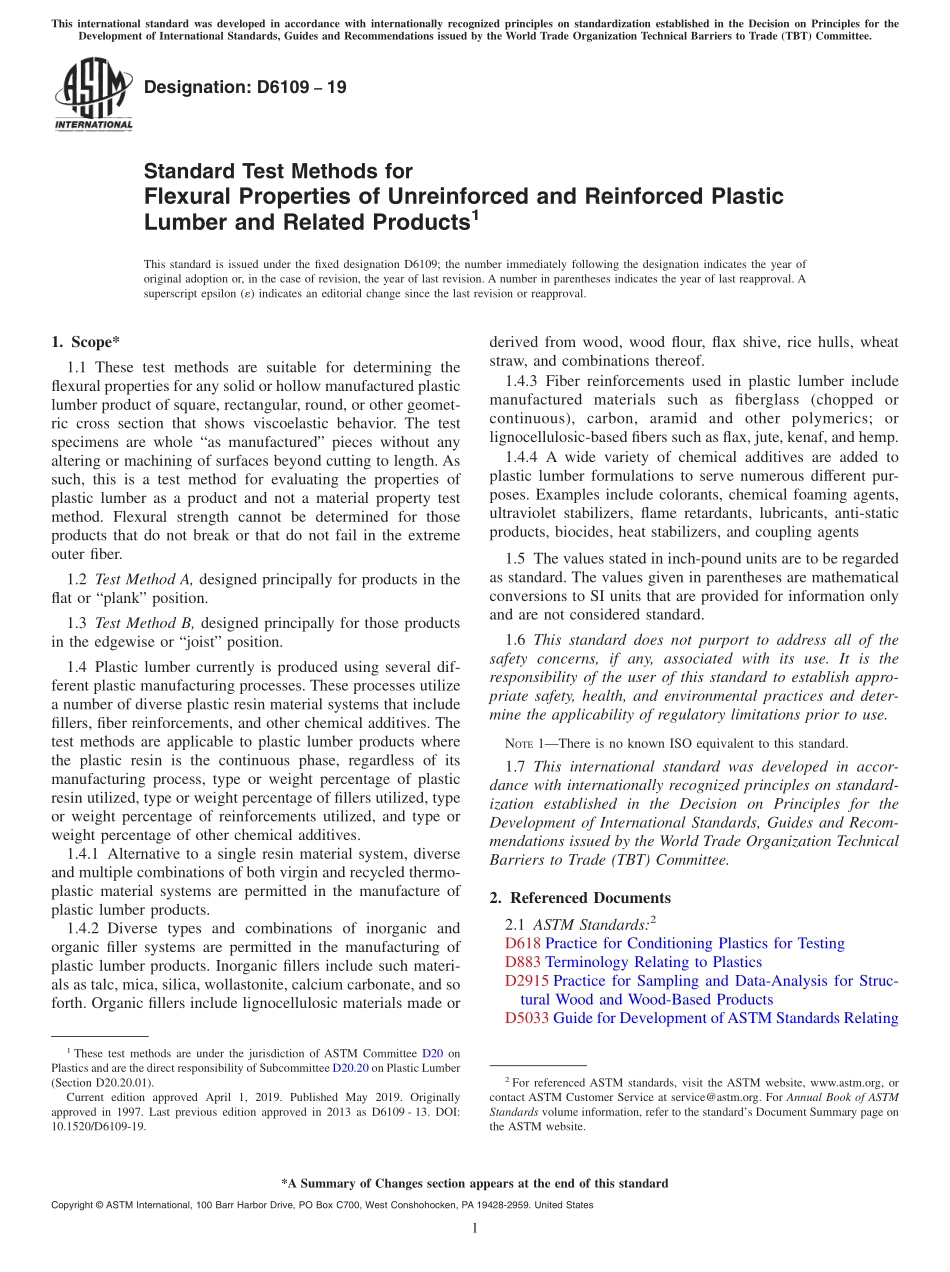

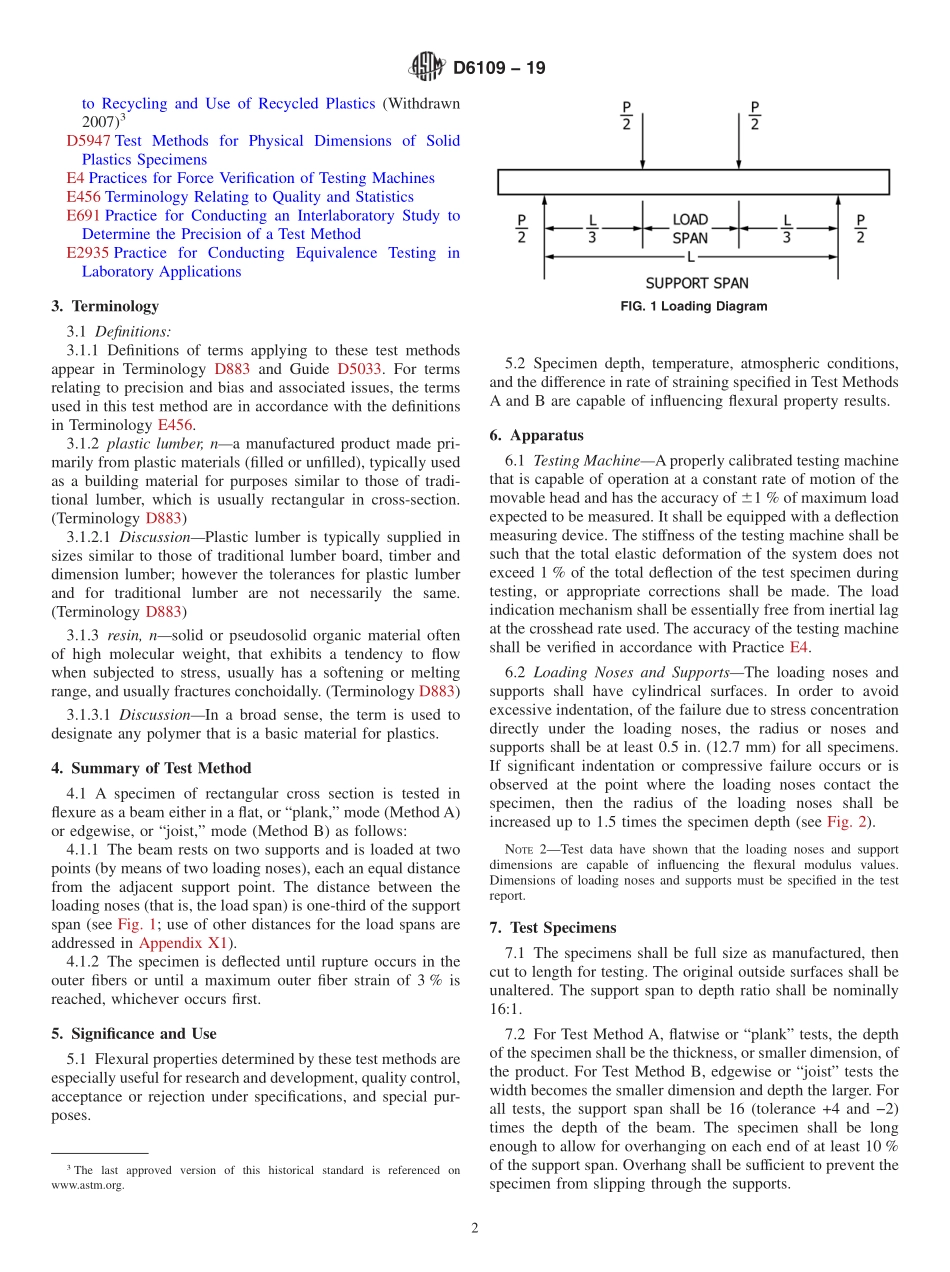

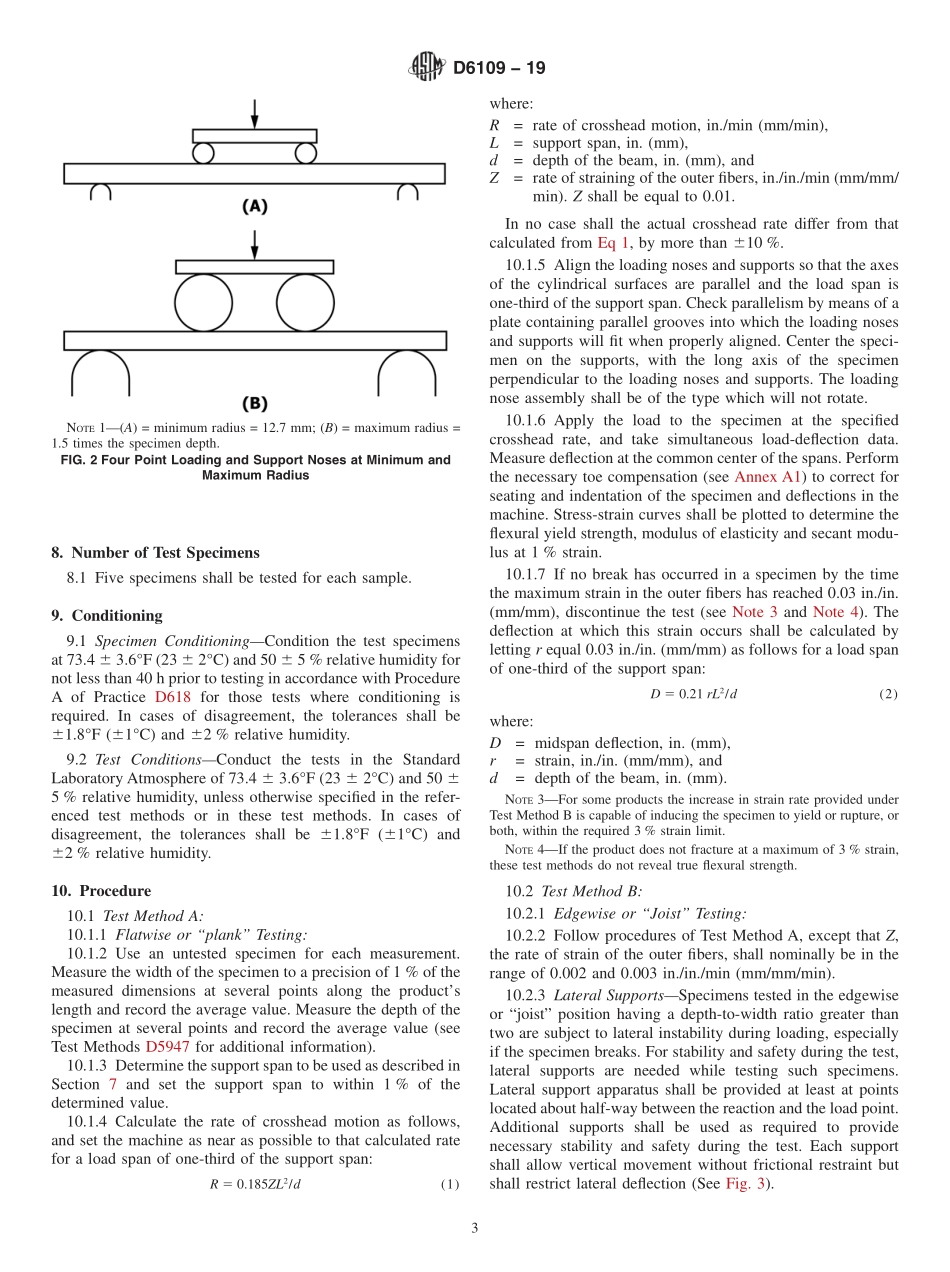

Designation:D6109−19StandardTestMethodsforFlexuralPropertiesofUnreinforcedandReinforcedPlasticLumberandRelatedProducts1ThisstandardisissuedunderthefixeddesignationD6109;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thesetestmethodsaresuitablefordeterminingtheflexuralpropertiesforanysolidorhollowmanufacturedplasticlumberproductofsquare,rectangular,round,orothergeomet-riccrosssectionthatshowsviscoelasticbehavior.Thetestspecimensarewhole“asmanufactured”pieceswithoutanyalteringormachiningofsurfacesbeyondcuttingtolength.Assuch,thisisatestmethodforevaluatingthepropertiesofplasticlumberasaproductandnotamaterialpropertytestmethod.Flexuralstrengthcannotbedeterminedforthoseproductsthatdonotbreakorthatdonotfailintheextremeouterfiber.1.2TestMethodA,designedprincipallyforproductsintheflator“plank”position.1.3TestMethodB,designedprincipallyforthoseproductsintheedgewiseor“joist”position.1.4Plasticlumbercurrentlyisproducedusingseveraldif-ferentplasticmanufacturingprocesses.Theseprocessesutilizeanumberofdiverseplasticresinmaterialsystemsthatincludefillers,fiberreinforcements,andotherchemicaladditives.Thetestmethodsareapplicabletoplasticlumberproductswheretheplasticresinisthecontinuousphase,regardlessofitsmanufacturingprocess,typeorweightpercentageofplasticresinutilized,typeorweightpercentageoffillersutilized,typeorweightpercentageofreinforcementsutilized,andtypeorweightpercentageofotherchemicaladditives.1.4.1Alternativetoasingleresinmaterialsystem,diverseandmultiplecombinationsofbothvirginandrecycledthermo-plasticmaterialsystemsarepermittedinthemanufactureofplasticlumberproducts.1.4.2Diversetypesandcombinationsofinorganicandorganicfillersystemsarepermittedinthemanufacturingofplasticlumberproducts.Inorganicfillersincludesuchmateri-alsastalc,mica,silica,wol...