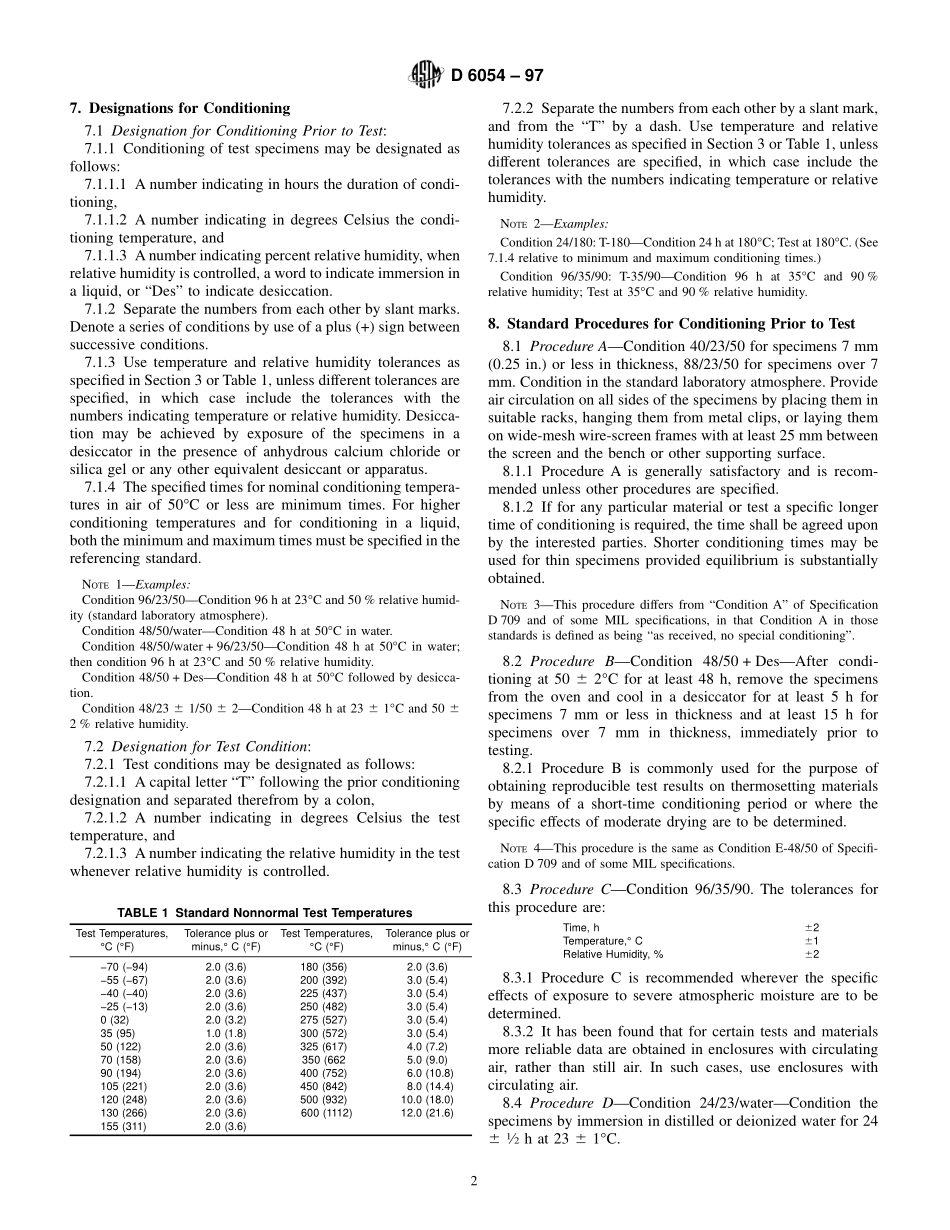

Designation:D6054–97AnAmericanNationalStandardStandardPracticeforConditioningElectricalInsulatingMaterialsforTesting1ThisstandardisissuedunderthefixeddesignationD6054;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thispracticecoversproceduresforconditioningelec-tricalinsulatingmaterials(althoughnotnecessarilytoequilib-rium)priortotestingandtheconditionsunderwhichtheyshallbetested.Ingeneralthephysicalandelectricalpropertiesofelectricalinsulatingmaterialsareinfluencedbytemperatureandrelativehumidityinamannerthatmateriallyaffectstestresults.Inorderthatreliablecomparisonsmaybemadeofdifferentmaterialsandbetweendifferentlaboratories,itisnecessarytostandardizethehumidityandtemperaturecondi-tionstowhichspecimensofthesematerialsaresubjectedpriortoandduringtesting.1.2ThispracticeissimilartoPracticeD618.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:D618PracticeforConditioningPlasticsforTesting2D709SpecificationforLaminatedThermosettingMateri-als3D1711TerminologyRelatingtoElectricalInsulation3D5032PracticeforMaintainingConstantRelativeHumid-itybyMeansofAqueousGlycerinSolutions43.Terminology3.1Definitions:3.1.1roomtemperature,n—atemperatureintherangefrom20to30°C.3.1.2standardlaboratoryatmosphere,n—anatmospherehavingatemperatureof2362°Candarelativehumidityof5065%.3.1.2.1Discussion—Whereclosertolerancesonatmo-sphericconditionsarerequired,61°Contemperatureor62%onrelativehumidity,orboth,maybespecified.3.1.3standardlaboratorytemperature,n—atemperatureof2362°C.3.1.4Fordefinitionsofothertermsrelatingtoelectricalinsulatingmaterial...