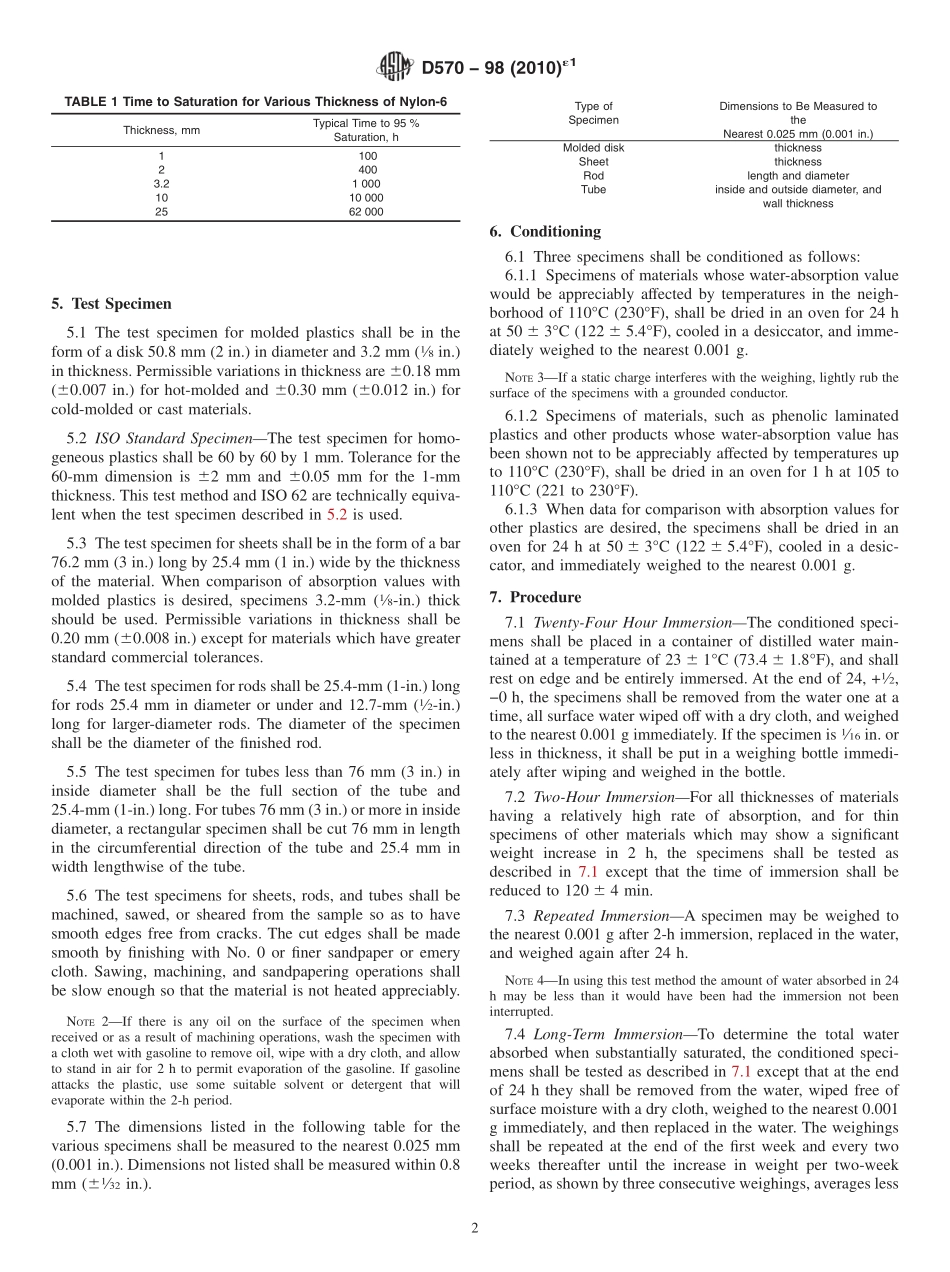

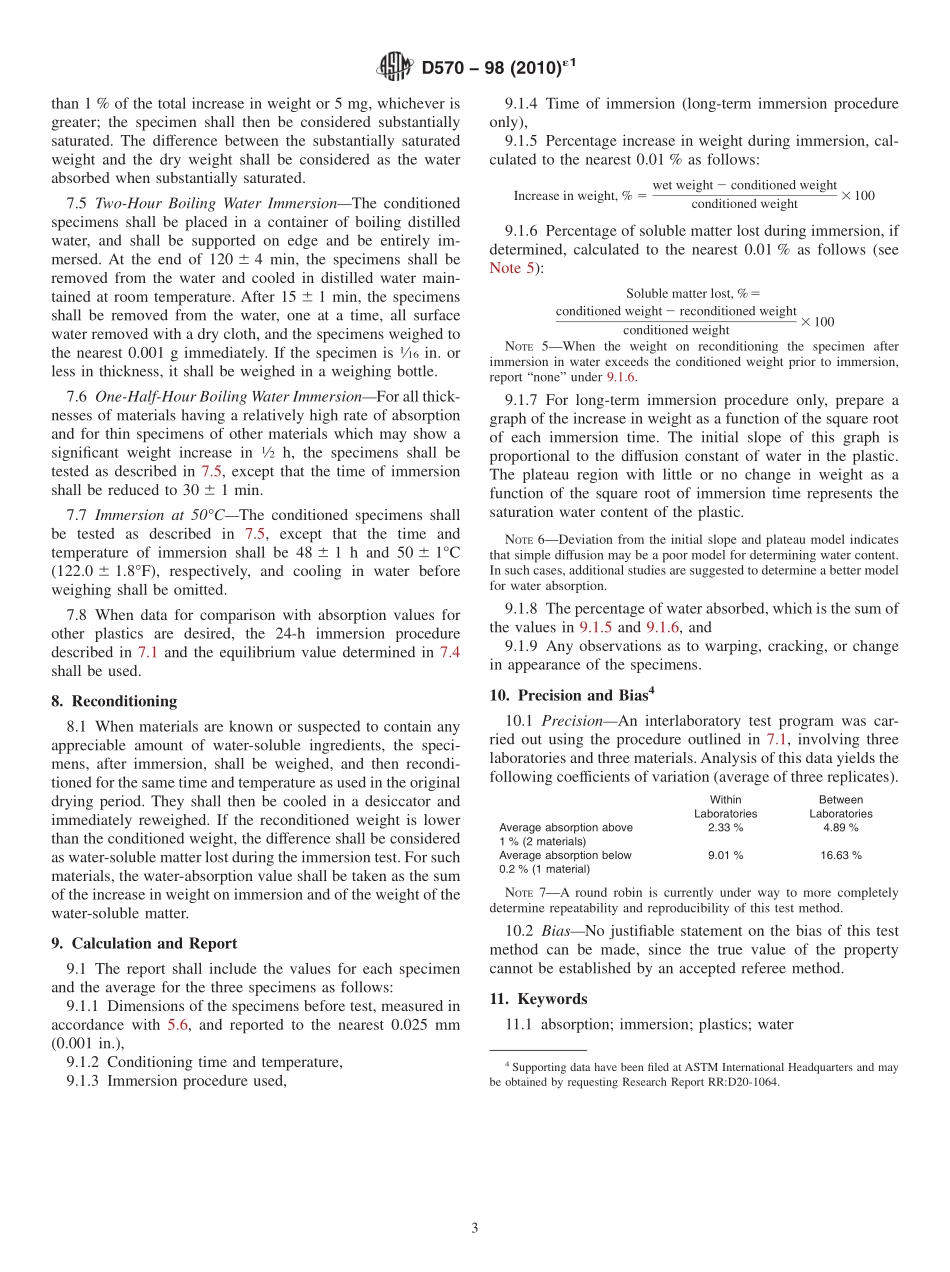

Designation:D570−98(Reapproved2010)´1StandardTestMethodforWaterAbsorptionofPlastics1ThisstandardisissuedunderthefixeddesignationD570;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheDepartmentofDefense.´1NOTE—RemovedASTMD647asareferenceddocumenteditoriallyinJune2010.1.Scope1.1Thistestmethodcoversthedeterminationoftherelativerateofabsorptionofwaterbyplasticswhenimmersed.Thistestmethodisintendedtoapplytothetestingofalltypesofplastics,includingcast,hot-molded,andcold-moldedresinousproducts,andbothhomogeneousandlaminatedplasticsinrodandtubeformandinsheets0.13mm(0.005in.)orgreaterinthickness.1.2ThevaluesgiveninSIunitsaretoberegardedasstandard.Thevaluesstatedinparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.NOTE1—ThisstandardisequivalenttoISO62.2.ReferencedDocuments2.1ISOStandard:ISO62Plastics—DeterminationofWaterAbsorption23.SignificanceandUse3.1Thistestmethodforrateofwaterabsorptionhastwochieffunctions:first,asaguidetotheproportionofwaterabsorbedbyamaterialandconsequently,inthosecaseswheretherelationshipsbetweenmoistureandelectricalormechanicalproperties,dimensions,orappearancehavebeendetermined,asaguidetotheeffectsofexposuretowaterorhumidconditionsonsuchproperties;andsecond,asacontroltestontheuniformityofaproduct.Thissecondfunctionisparticu-larlyapplicabletosheet,rod,andtubearmswhenthetestismadeonthefinishedproduct.3.2Comparisonofwaterabsorptionvaluesofvariousplas-ticscanbemadeonthebasisofvaluesobtainedinaccordancewith7.1and7.4.3.3Idealdiffusionofliquids3intopolymersisafunctionofthesqua...