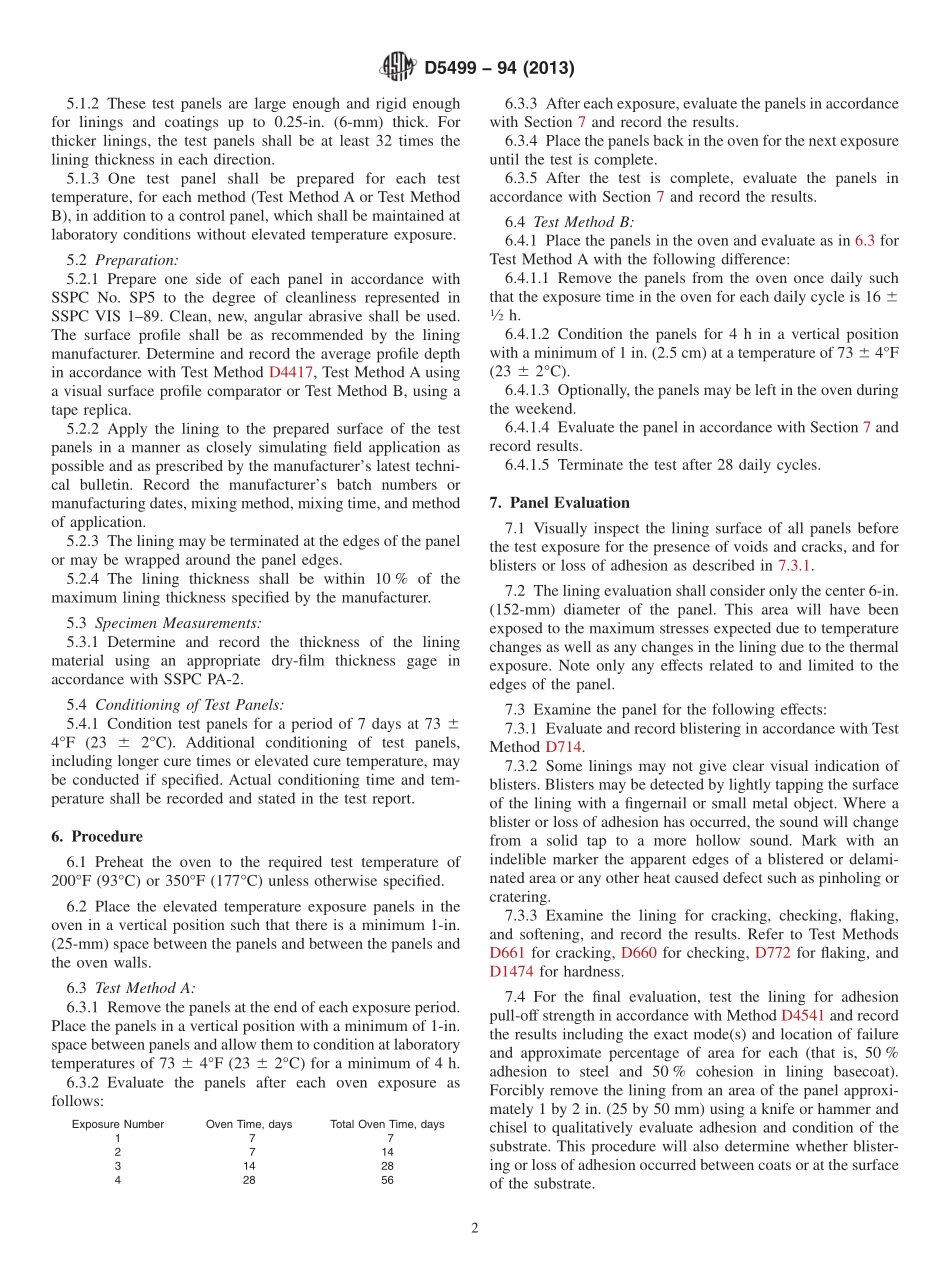

Designation:D5499−94(Reapproved2013)StandardTestMethodsforHeatResistanceofPolymerLiningsforFlueGasDesulfurizationSystems1ThisstandardisissuedunderthefixeddesignationD5499;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodisintendedtoevaluatetheresistanceofpolymerliningsappliedtocarbonsteelsubstratestoelevatedtemperatures.Twoseparatemethodsareincludedasfollows:1.1.1TestMethodAContinuouselevatedtemperatureexposure,and1.1.2TestMethodBCyclingelevatedtemperatureexpo-sure.1.2Thevaluesstatedininch-poundunitsaretoberegardedasstandard.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2A36/A36MSpecificationforCarbonStructuralSteelD660TestMethodforEvaluatingDegreeofCheckingofExteriorPaintsD661TestMethodforEvaluatingDegreeofCrackingofExteriorPaintsD714TestMethodforEvaluatingDegreeofBlisteringofPaintsD772TestMethodforEvaluatingDegreeofFlaking(Scal-ing)ofExteriorPaintsD1474TestMethodsforIndentationHardnessofOrganicCoatingsD4417TestMethodsforFieldMeasurementofSurfaceProfileofBlastCleanedSteelD4541TestMethodforPull-OffStrengthofCoatingsUsingPortableAdhesionTesters2.2SteelStructuresPaintingCouncilStandards(SSPC):3SSPCVIS1–89VisualStandardSSPCNo.SP5BlastCleaningtoWhiteMetalSSPCPA-2MeasurementofDryPaintThicknesswithMagneticGauges3.SignificanceandUse3.1Theresultsobtainedbythesetestmethodscanbeusedincombinationwithothertestmethodsfortheselectionofalininginfluegasdesulfurization(FGD)systems.3.2Thesemethodsarei...