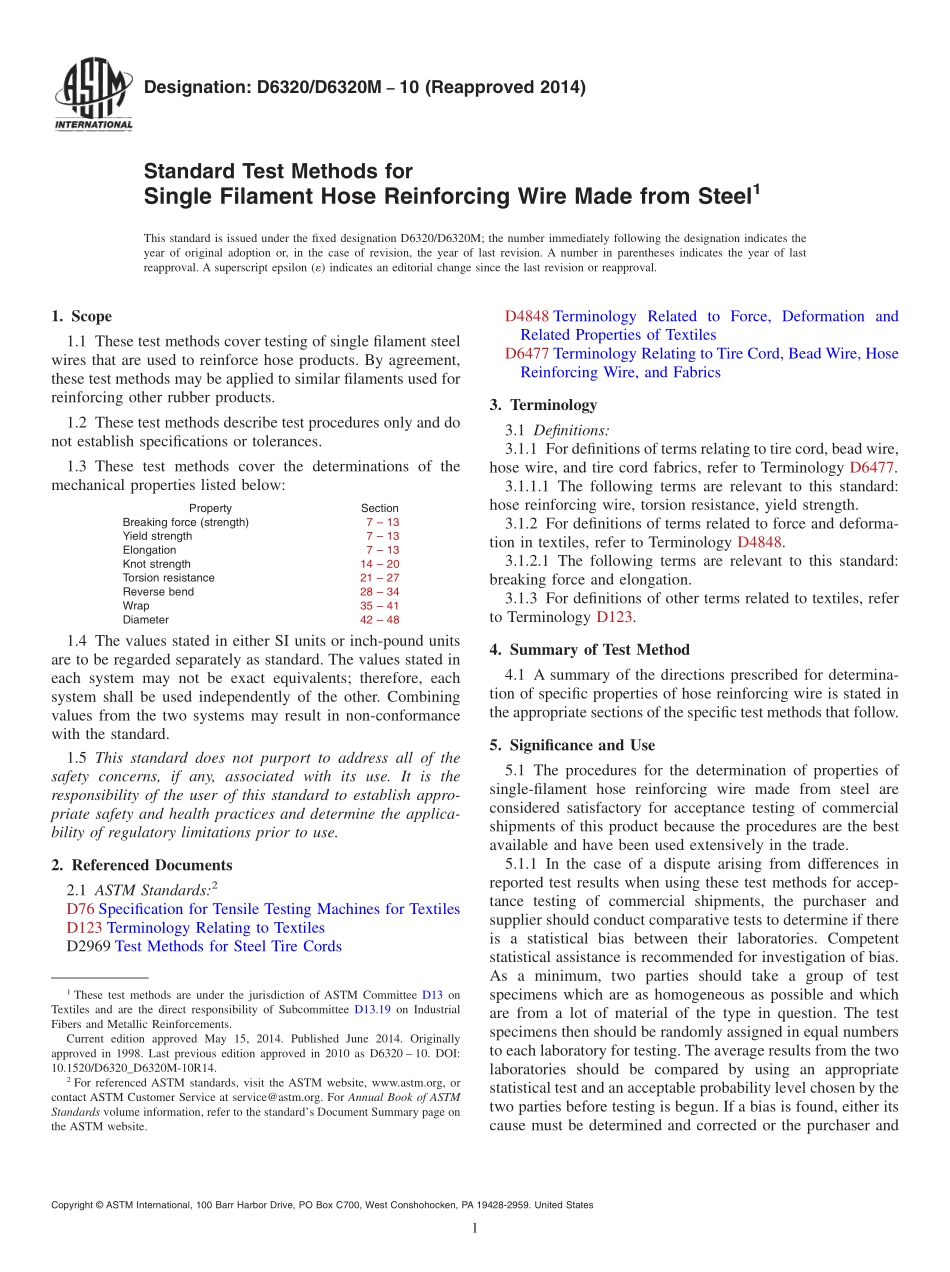

Designation:D6320/D6320M−10(Reapproved2014)StandardTestMethodsforSingleFilamentHoseReinforcingWireMadefromSteel1ThisstandardisissuedunderthefixeddesignationD6320/D6320M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thesetestmethodscovertestingofsinglefilamentsteelwiresthatareusedtoreinforcehoseproducts.Byagreement,thesetestmethodsmaybeappliedtosimilarfilamentsusedforreinforcingotherrubberproducts.1.2Thesetestmethodsdescribetestproceduresonlyanddonotestablishspecificationsortolerances.1.3Thesetestmethodscoverthedeterminationsofthemechanicalpropertieslistedbelow:PropertySectionBreakingforce(strength)7–13Yieldstrength7–13Elongation7–13Knotstrength14–20Torsionresistance21–27Reversebend28–34Wrap35–41Diameter42–481.4ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.1.5Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D76SpecificationforTensileTestingMachinesforTextilesD123TerminologyRelatingtoTextilesD2969TestMethodsforSteelTireCordsD4848TerminologyRelatedtoForce,DeformationandRelatedPropertiesofTextilesD6477TerminologyRelatingtoTireCord,BeadWire,HoseReinforcingWire,andFabrics3.Terminology3.1Definitions:3.1.1Fordefinitionsoftermsrelatingtotirecord,beadwire,hosewire,andtirecordfabrics,refertoTerminologyD6477.3.1.1.1Thefollowingtermsarerelevanttothisstandard:hosereinforcingwire,torsionresistance,yieldstrength.3....