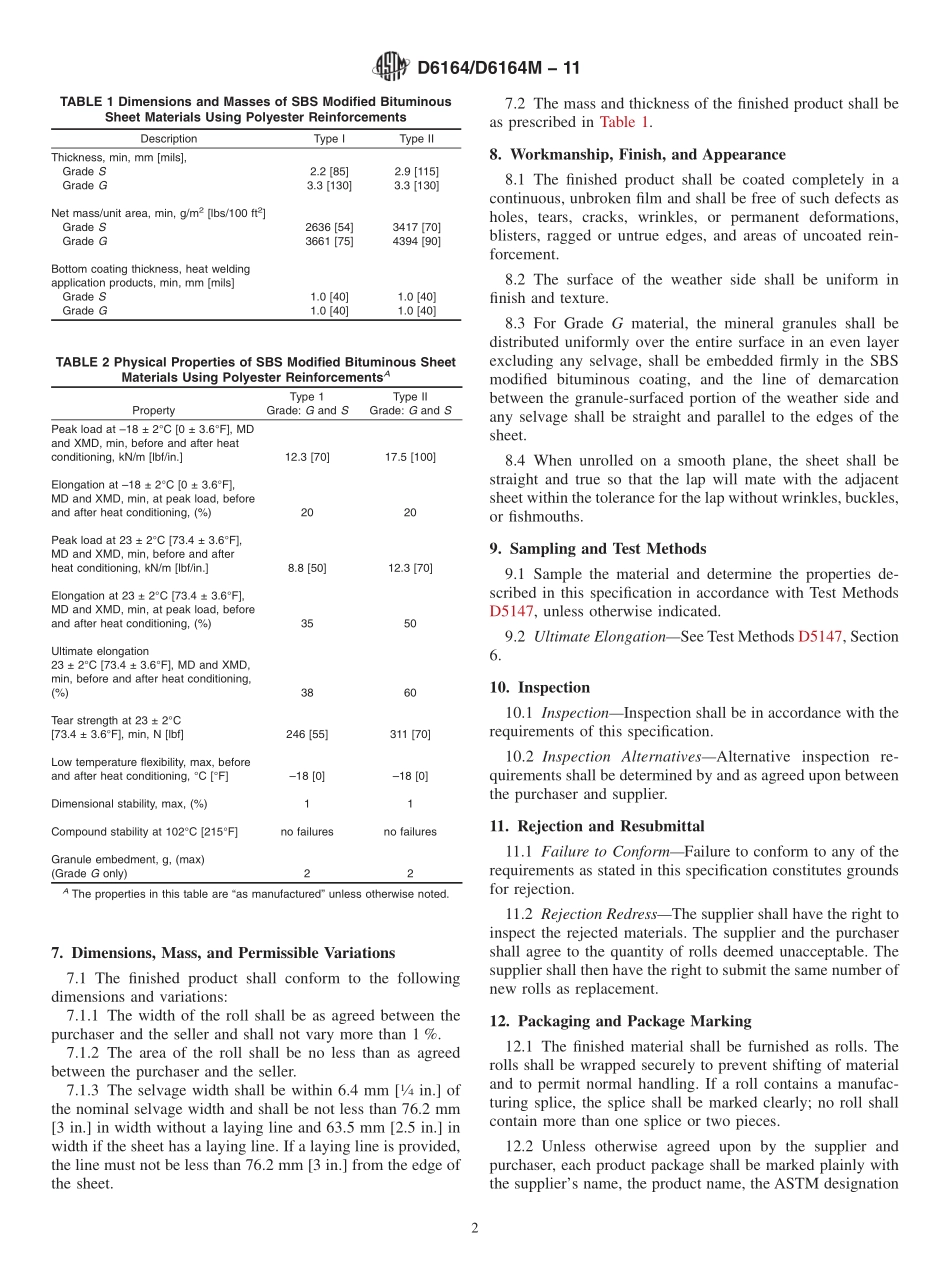

Designation:D6164/D6164M−11StandardSpecificationforStyreneButadieneStyrene(SBS)ModifiedBituminousSheetMaterialsUsingPolyesterReinforcements1ThisstandardisissuedunderthefixeddesignationD6164/D6164M;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoversprefabricatedmodifiedbitumi-noussheetmaterialsreinforcedwithpolyesterfabricastheprimaryreinforcement,(seeNote1)withorwithoutgranules,whichusestyrenebutadienestyrene(SBS)thermoplasticelastomerastheprimarymodifierandareintendedforuseinthefabricationofmultipleplyroofingandwaterproofingmembranes.NOTE1—Manymodifiedbituminoussheetsarecurrentlymarketedwithpolyestermatreinforcedwithglassyarnstoimproveprocessinginthemanufactureofthefinishedmodifiedbitumenproductandtoreducedistortionsthatmaybeintroducedduringproduction.TheseglassyarnsaretypicallyasmallpercentageofthereinforcementanddonotcontributetothephysicalpropertiesofthefinishedproductsomuchastomaketheseproductsbeclassifiedbyD6162.1.2Thisspecificationisintendedasamaterialspecificationonly.Issuesregardingthesuitabilityofthespecificroofconstructionsorapplicationtechniquesarebeyondthisscope.1.3Thespecifiedtestsandpropertylimitsusedtocharac-terizethesheetmaterialsareintendedtoestablishminimumproperties.In-placeroofsystemdesigncriteria,suchasfireresistance,fieldstrength,impact/punctureresistance,materialcompatibility,upliftresistance,andothers,arefactorsbeyondthescopeofthismaterialspecification.1.4ThevaluesstatedineitherSIunitsorinch-poundunitsaretoberegardedseparatelyasstandard.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.Combiningvaluesfromthetwosystemsmayresultinnon-conformancewiththestandard.2.ReferencedDocuments2.1ASTMStandards:2D1079TerminologyRelatingtoRoofingandWaterproofingD...