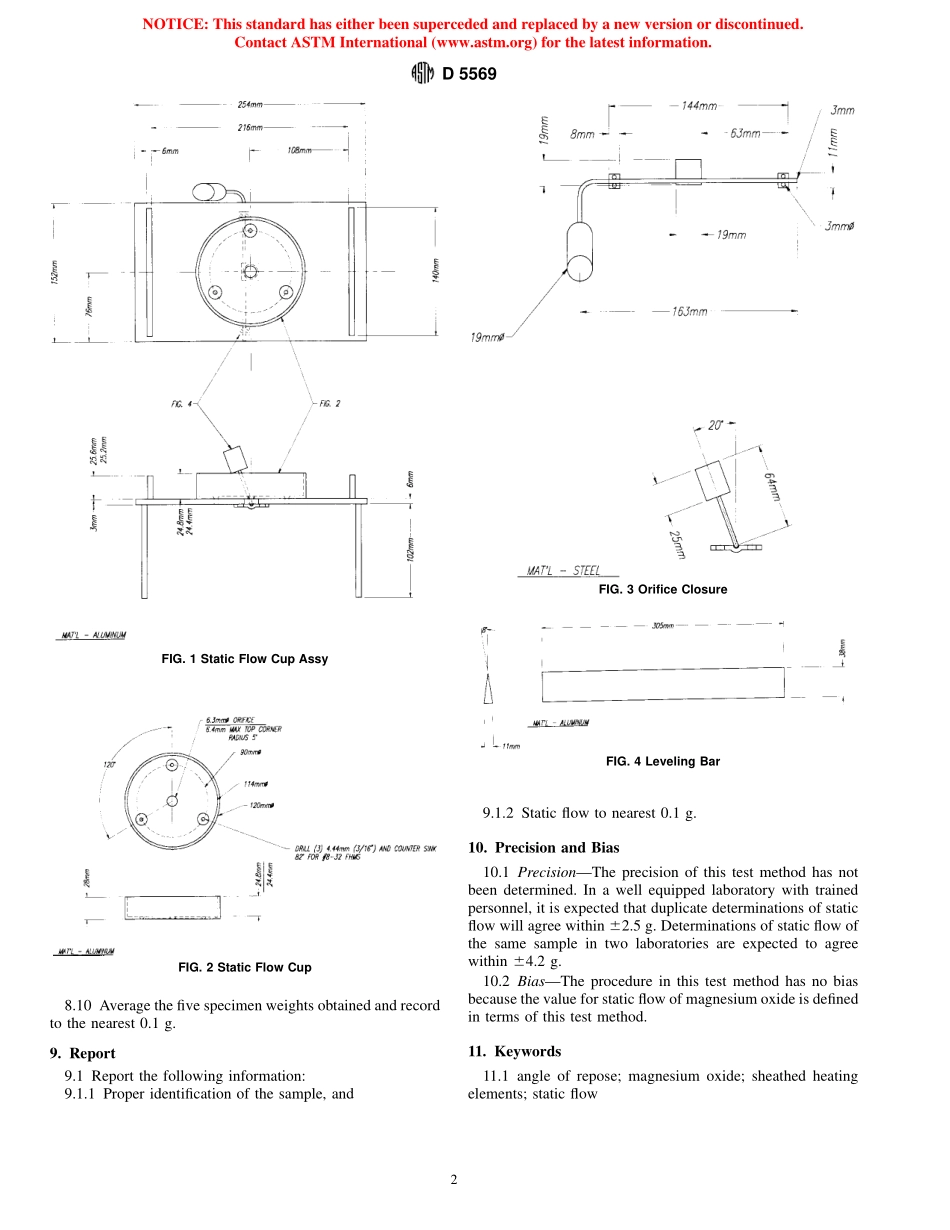

Designation:D5569–94AnAmericanNationalStandardStandardTestMethodfortheDeterminationofStaticFlowofElectricalGradeMagnesiumOxideforUseinSheathedHeatingElements1ThisstandardisissuedunderthefixeddesignationD5569;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthedeterminationofthestaticflowofelectricalgrademagnesiumoxideforuseinsheathedheatingelements.1.2Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.1.3ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.2.ReferencedDocuments2.1ASTMStandards:D2755TestMethodofSamplingandReductiontoTestWeightofElectricalGradeMagnesiumOxide23.Terminology3.1Definitions:3.1.1angleofrepose,n—theangleformedwiththehori-zontalwhenabulksolidmoves,undertheinfluenceofgravity,overastationarybulksolid,toadynamicequilibrium.4.SummaryofTestMethod4.1Granularmagnesiumoxideisallowedtoflowthrougha6.35-mm(1⁄4-in.)diameterorificefroma25.4-mm(1-in.)deepbedofmaterial.Theweightingramsofmagnesiumoxideflowingthroughtheorificebygravityisrecordedasitsstaticflow.5.SignificanceandUse5.1Thestaticflowisanindicatorofangleofreposeofgranularmagnesiumoxide.Sheathedheating-elementfilling-equipmentperformanceisaffectedbytheflowcharacteristicsofmagnesiumoxideasdeterminedbythistestmethod.6.Apparatus6.1StaticFlowCup,withinsidedimensionsof114.3-mm(4.5-in.)diameterand24.6-mm(31⁄32-in.)depthwitha6.35-mm(0.25-in.)diametercenteredorifice,equippedwithrailsat0.8mm(1⁄32in.)aboverimofcup,two110.6-mm(4-in.)highby139.7-mm(5.5-in.)widelegs,andorificeclosurewithhandle(seeFig.1,Fig.2,andFig.3forsuggesteddesign).6...