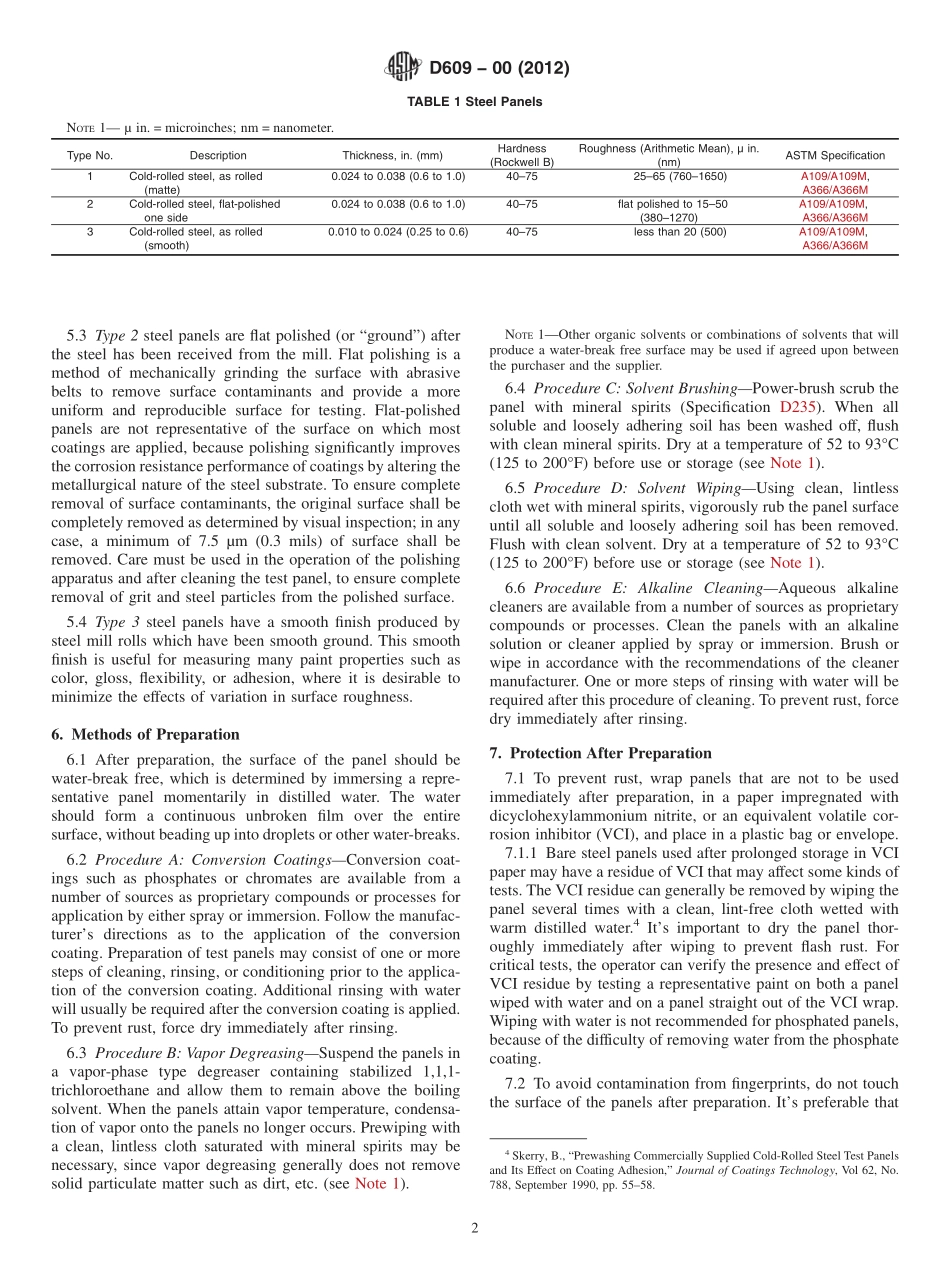

Designation:D609−00(Reapproved2012)StandardPracticeforPreparationofCold-RolledSteelPanelsforTestingPaint,Varnish,ConversionCoatings,andRelatedCoatingProducts1ThisstandardisissuedunderthefixeddesignationD609;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheDepartmentofDefense.1.Scope1.1Thispracticecoversvarioustypesofcoldrolledsteelpanelsandtheprocedurestobefollowedintheirpreparationfortestingpaint,varnish,lacquer,conversioncoatings,andrelatedproducts.1.2Theproceduresareasfollows:ProcedureA—Conversioncoatings(phosphates,chromates,etc.)ProcedureB—VapordegreasingProcedureC—SolventbrushingProcedureD—SolventwipingProcedureE—Alkalinecleaning1.3ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.4Thisstandarddoesnotpurporttoaddressthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafetyandhealthpracticesanddeterminetheapplicabilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2A109/A109MSpecificationforSteel,Strip,Carbon(0.25MaximumPercent),Cold-RolledA366/A366MSpecificationforCommercialSteel(CS)Sheet,Carbon,(0.15MaximumPercent)Cold-Rolled(Withdrawn2000)3D235SpecificationforMineralSpirits(PetroleumSpirits)(HydrocarbonDryCleaningSolvent)3.SummaryofPractice3.1SeveralproceduresforpreparationandcleaningofsteeltestpanelsaredescribedasshowninTable1.4.SignificanceandUse4.1Theproceduresdescribedinthispracticearedesignedtoprovidesteelpanelswithauniformandreproduciblesurfacefortestingofpaint,varnish,lacquer,conversioncoatings,andrelatedproducts.5.TestPanels5.1Preparethetestpanelsfromrustandstain-freecold-rolledsteelasdescribedin5.2,5.3,5.4,andTable1.Thepanelsshallbemadetoasizeandthickne...