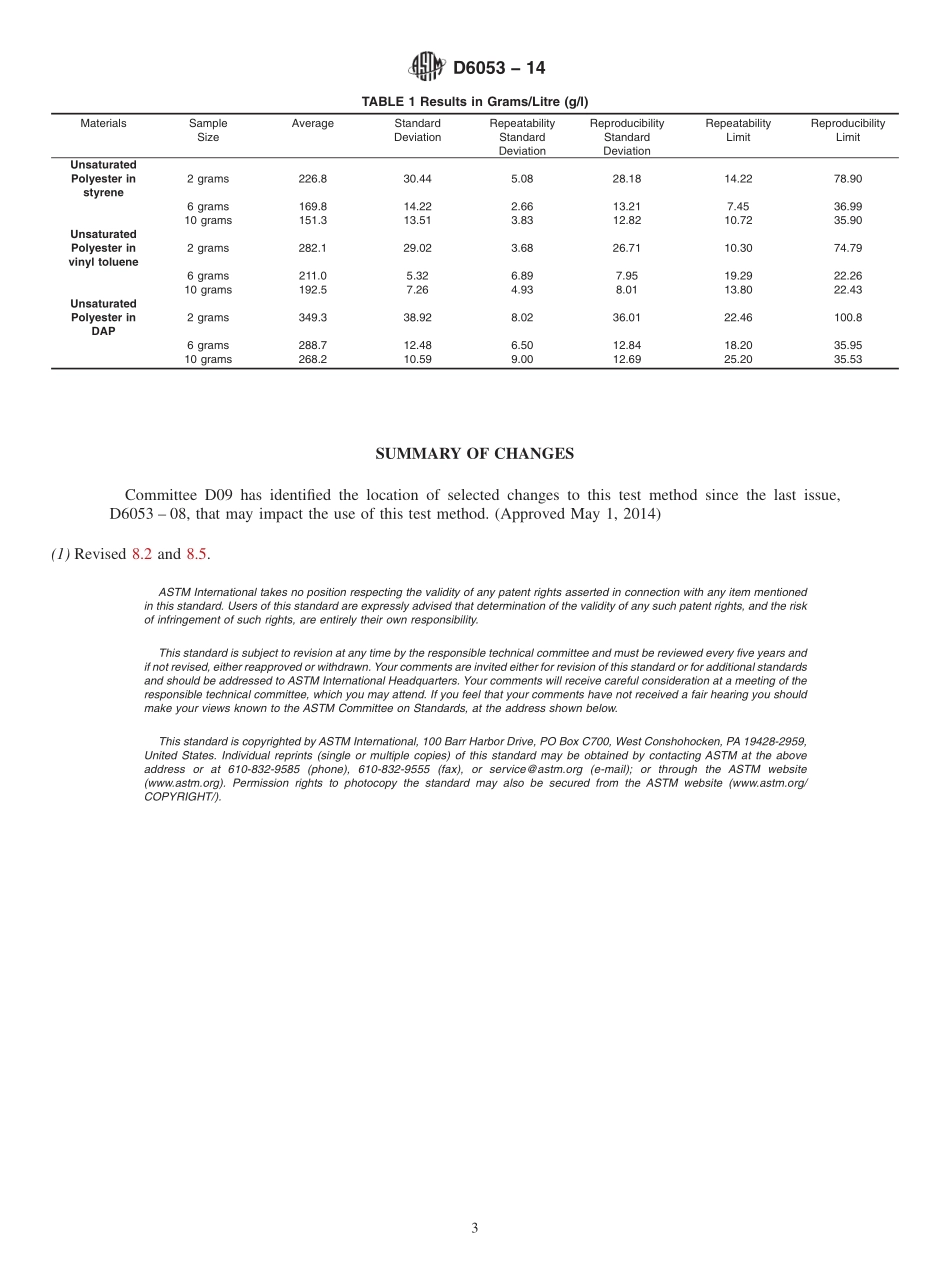

Designation:D6053−14AnAmericanNationalStandardStandardTestMethodforDeterminationofVolatileOrganicCompound(VOC)ContentofElectricalInsulatingVarnishes1ThisstandardisissuedunderthefixeddesignationD6053;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thistestmethodcoversthedeterminationoftheamountofvolatileorganiccompoundsemittedduringcureofelectricalinsulatingvarnishes.1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.Thevaluesgiveninparenthesesaremathematicalconversionstoinch-poundunitsthatareprovidedforinforma-tiononlyandarenotconsideredstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.SeeSection7forspecificprecautions.2.ReferencedDocuments2.1ASTMStandards:2D115TestMethodsforTestingSolventContainingVar-nishesUsedforElectricalInsulationD1711TerminologyRelatingtoElectricalInsulationD3960PracticeforDeterminingVolatileOrganicCompound(VOC)ContentofPaintsandRelatedCoatingsD4733TestMethodsforSolventlessElectricalInsulatingVarnishesD5423SpecificationforForced-ConvectionLaboratoryOv-ensforEvaluationofElectricalInsulationE691PracticeforConductinganInterlaboratoryStudytoDeterminethePrecisionofaTestMethod3.Terminology3.1DefinitionsofTermsSpecifictoThisStandard:3.1.1varnish,electricalinsulating,n—aliquidresinsystemthatisappliedtoandcuredonelectricalcomponentsprovidingelectrical,mechanical,andenvironmentalprotection.3.1.1.1Discussion—Therearetwotypesofelectricalinsu-latingvarnish:solvent-containingandsolventless.Thesolvent-containingvarnishisasolution,dispersion,oremulsionofapolymerormixtureofpolymersinavolatile,nonreactableliquid.Thesolventlesstypeisaliquidr...