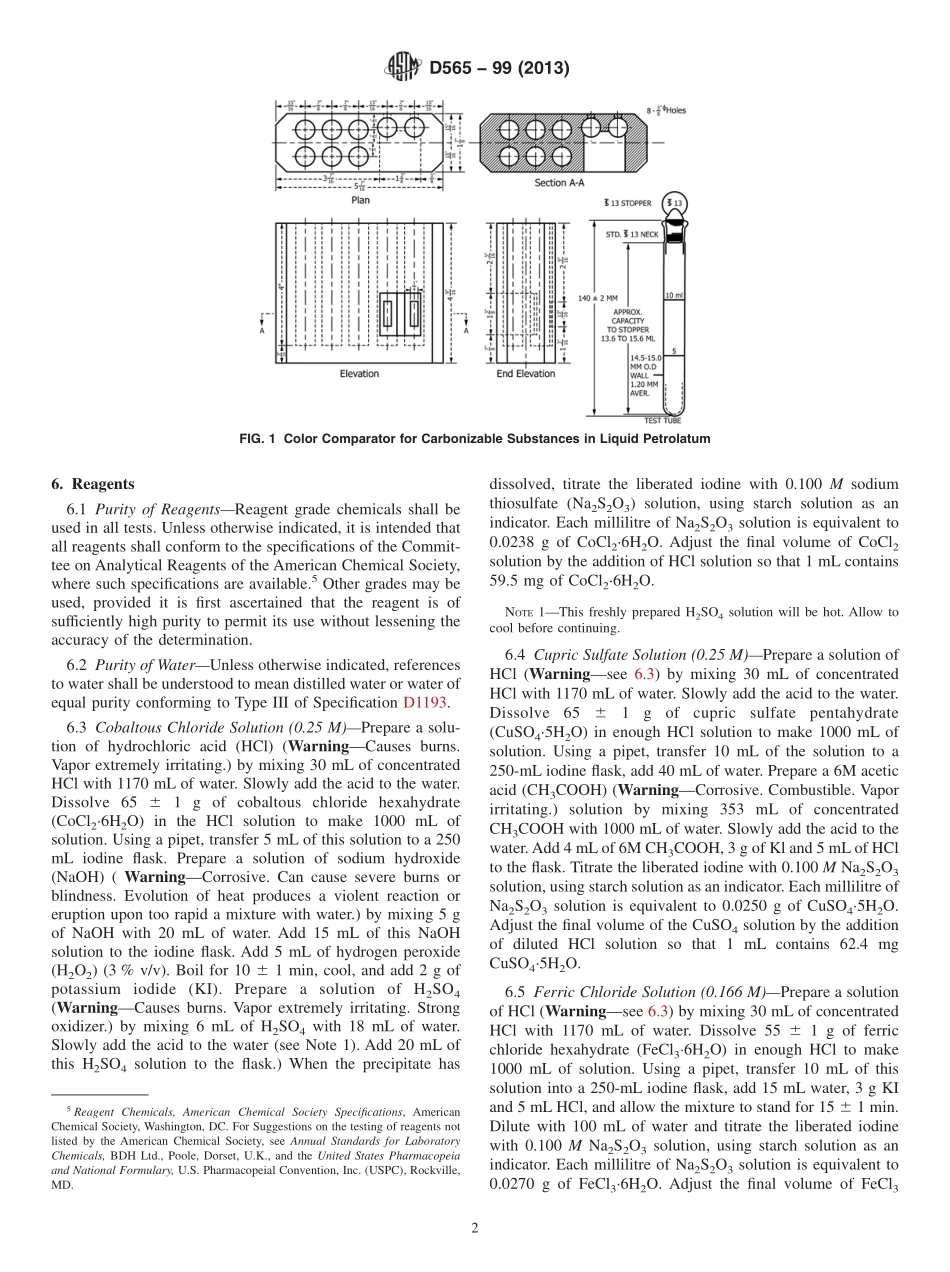

Designation:D565−99(Reapproved2013)StandardTestMethodforCarbonizableSubstancesinWhiteMineralOil1ThisstandardisissuedunderthefixeddesignationD565;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope1.1Thistestmethodcoverswhitemineraloil(MineralOilUSPandLightMineralOilNF)todeterminewhetheritconformstothestandardofqualityrequiredforpharmaceuticaluseasdefinedbytheUnitedStatesPharmacopeiaandtheNationalFormulary,ortheFoodandDrugAdministration.1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.2.1Exception—DimensionrequirementsforthecolorcomparatorinFig.1areinSIandinch-poundunits.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.Forspecifichazardstatements,seeSection6.2.ReferencedDocuments2.1ASTMStandards:2D1193SpecificationforReagentWater2.2OffıcialCompendia:3UnitedStatesPharmacopeia—CurrentEditionMonographonMineralOilNationalFormulary—CurrentEditionMonographonLightMineralOil2.3GovernmentDocument:421CFR172.878FoodandDrugAdministrationTitle3.SummaryofTestMethod3.1Themineraloilistreatedwithconcentratedsulfuricacid(H2SO4)underprescribedconditionsandtheresultingcoloriscomparedwithareferencestandardtodeterminewhetheritpassesorfailsthetest.4.SignificanceandUse4.1ThistestmethodisameansforascertainingwhetherpharmaceuticalmineraloilconformstothestandardsoftheUnitedStatesPharmacopeia,theNationalFormulary,andtheFoodandDrugAdministration.5.Apparatus5.1TestTube,asshowninFig.1,ofheat-resistantglassfittedwithawell-groundglassstopper,thestopperandthetubebeari...