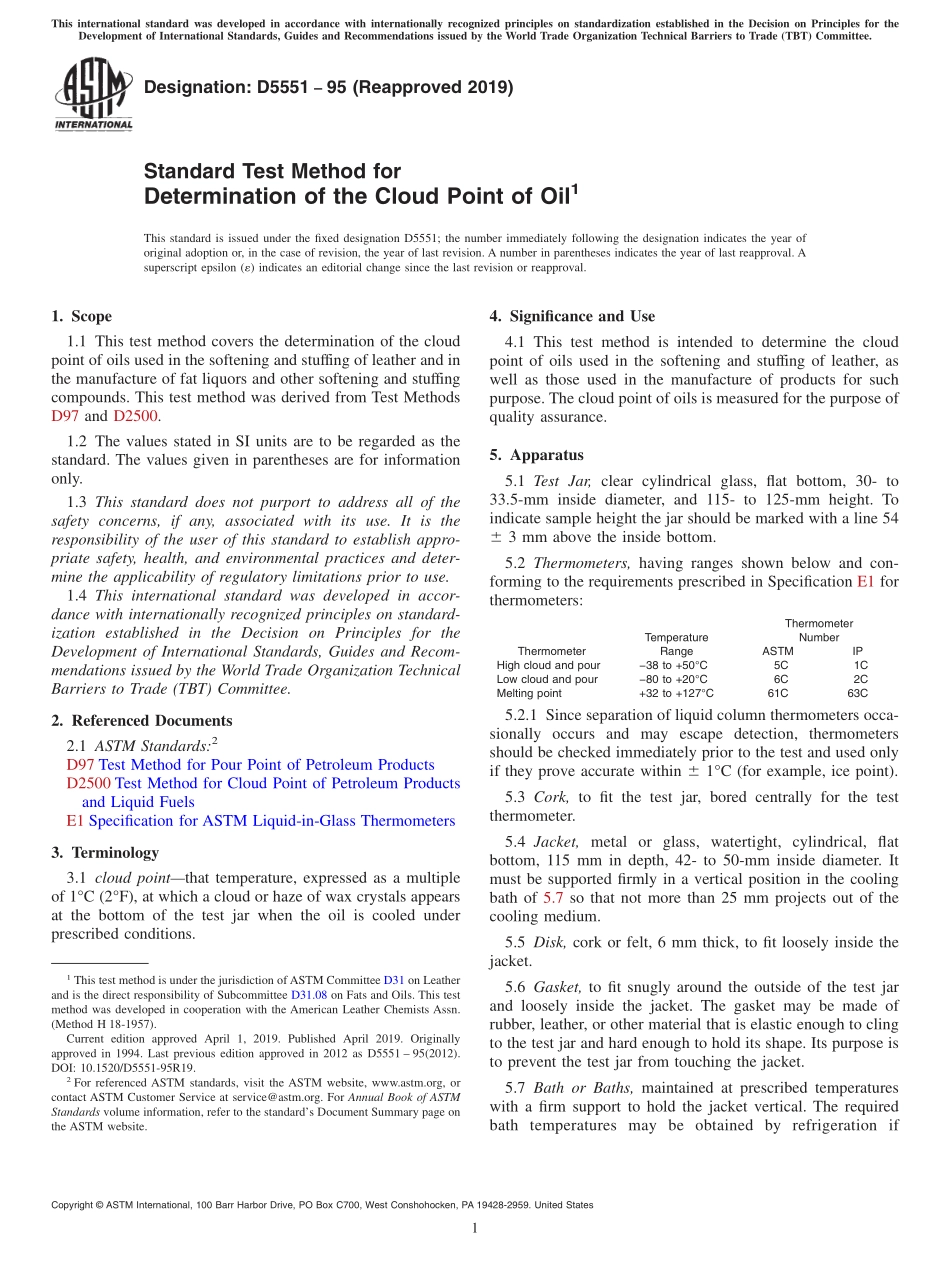

Designation:D5551−95(Reapproved2019)StandardTestMethodforDeterminationoftheCloudPointofOil1ThisstandardisissuedunderthefixeddesignationD5551;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthedeterminationofthecloudpointofoilsusedinthesofteningandstuffingofleatherandinthemanufactureoffatliquorsandothersofteningandstuffingcompounds.ThistestmethodwasderivedfromTestMethodsD97andD2500.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.1.4Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D97TestMethodforPourPointofPetroleumProductsD2500TestMethodforCloudPointofPetroleumProductsandLiquidFuelsE1SpecificationforASTMLiquid-in-GlassThermometers3.Terminology3.1cloudpoint—thattemperature,expressedasamultipleof1°C(2°F),atwhichacloudorhazeofwaxcrystalsappearsatthebottomofthetestjarwhentheoiliscooledunderprescribedconditions.4.SignificanceandUse4.1Thistestmethodisintendedtodeterminethecloudpointofoilsusedinthesofteningandstuffingofleather,aswellasthoseusedinthemanufactureofproductsforsuchpurpose.Thecloudpointofoilsismeasuredforthepurposeofqualityassurance.5.Apparatus5.1TestJar,clearcylindricalglass,flatbottom,30-to33.5-mminsidediameter,and115-to125-mmheight.Toindicates...