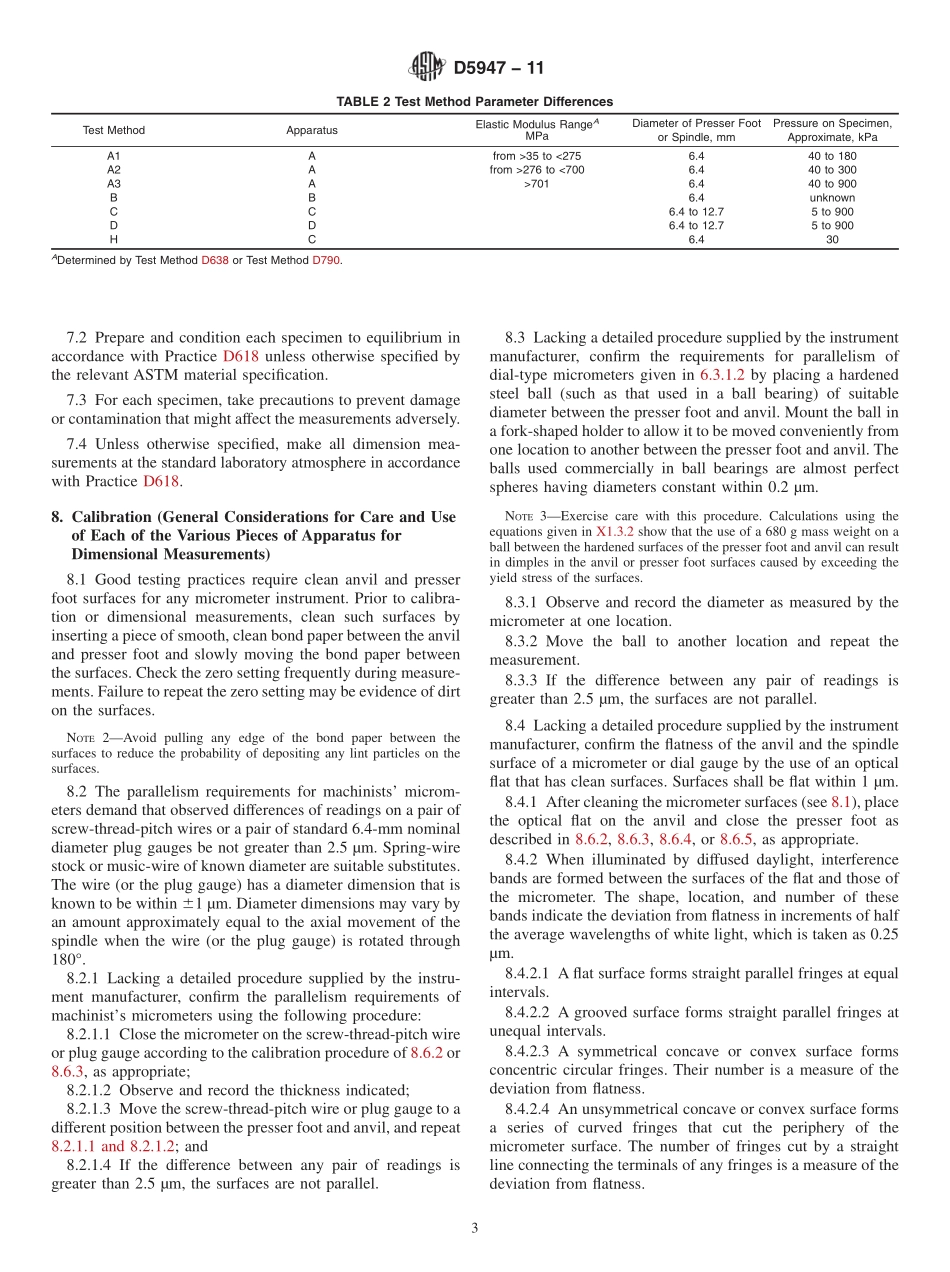

Designation:D5947−11StandardTestMethodsforPhysicalDimensionsofSolidPlasticsSpecimens1ThisstandardisissuedunderthefixeddesignationD5947;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thesetestmethodscoverdeterminationofthephysicaldimensionsofsolidplasticspecimenswherethedimensionsareuseddirectlyindeterminingtheresultsoftestsforvariousproperties.Usethesetestmethodsexceptasotherwiserequiredinmaterialspecifications.1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.NOTE1—ThisstandardandISO16012addressthesamesubjectmatter,butdifferintechnicalcontent.2.ReferencedDocuments2.1ASTMStandards:2D618PracticeforConditioningPlasticsforTestingD638TestMethodforTensilePropertiesofPlasticsD790TestMethodsforFlexuralPropertiesofUnreinforcedandReinforcedPlasticsandElectricalInsulatingMateri-alsD883TerminologyRelatingtoPlasticsD2240TestMethodforRubberProperty—DurometerHard-ness2.2ISOStandards:3ISO472Plastics—VocabularyISO16012Plastics—DeterminationofLinearDimensionsofTestSpecimens3.Terminology3.1Definitions—SeeTerminologyD883andISO472fordefinitionspertinenttothesetestmethods.3.2DefinitionsofTermsSpecifictoThisStandard:3.2.1absoluteuncertainty(ofameasurement),n—thesmallestdivisionthatmaybereaddirectlyontheinstrumentusedformeasurement.3.2.2calibration—thesetofoperationsthatestablishes,underspecifiedconditions,therelationshipbetweenvaluesmeasuredorindicatedbyaninstrumentorsystem,andthecorrespondingreferencestandardorknownvaluesderivedfromtheappropriatereferencestandards.3.2.3micrometer,n—aninstrumentformeasuringanydi-mensio...