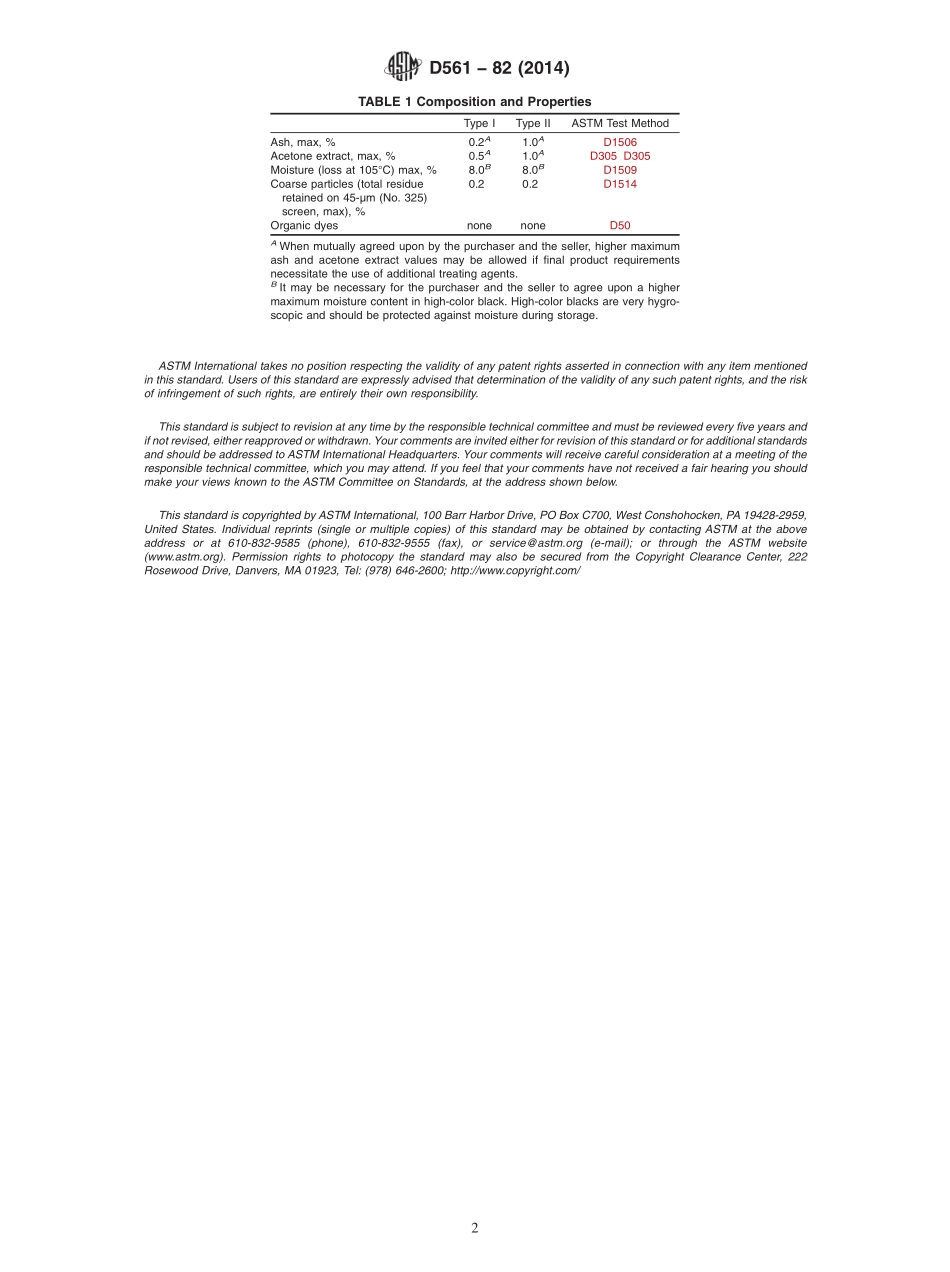

Designation:D561−82(Reapproved2014)StandardSpecificationforCarbonBlackPigmentforPaint1ThisstandardisissuedunderthefixeddesignationD561;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thisspecificationcoversthepigmentcommerciallyknownascarbonblack,whichissuitableforuseinthemanufactureofprotectiveordecorativecoatings.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.2.ReferencedDocuments2.1ASTMStandards:2D50TestMethodsforChemicalAnalysisofYellow,Orange,Red,andBrownPigmentsContainingIronandManga-neseD305TestMethodforSolvent-ExtractableMaterialinBlackPigmentsD387TestMethodforColorandStrengthofChromaticPigmentswithaMechanicalMullerD1506TestMethodsforCarbonBlack—AshContentD1509TestMethodsforCarbonBlack—HeatingLossD1514TestMethodforCarbonBlack—SieveResidue3.CompositionandProperties3.1Thepigmentshallbemadebyburningnaturalgas(TypeI)oroil(TypeII)insuchamannerastoformadepositofcarbon.Itshallbefreeofadulterantsandbeintheformofpowderordustlesspelletsandshallconformtotherequire-mentsspecifiedinTable1.3.2ThemasscolorandcharacterofthetintandtintingstrengthformedbyamixturewithawhitepigmentshallbewithinmutuallyagreeduponlimitsofastandardacceptabletoboththepurchaserandthesellerwhentestedinaccordancewithTestMethodD387.NOTE1—Forthetintingstrengthtestaratioof100partsofwhiteto1partofblackisusuallysuitable.4.Sampling4.1Twosamplesshallbetakenatrandomfromdifferentpackagesfromeachlot,batch,day’spack,orotherunitofproductioninashipment.Whennomarkingsdistinguishingbetweenunitsofproductionappear,samplesshallbetakenfromdifferentpackagesintheratiooftwosamplesforeach5000kg(10000lb),exceptthatforshipmentsoflessthan10000lbtwosamplesshallbetaken.4.2Attheoptionofthepurchaser,thesamplesmaybetestedseparatelyor,afterblendingthes...