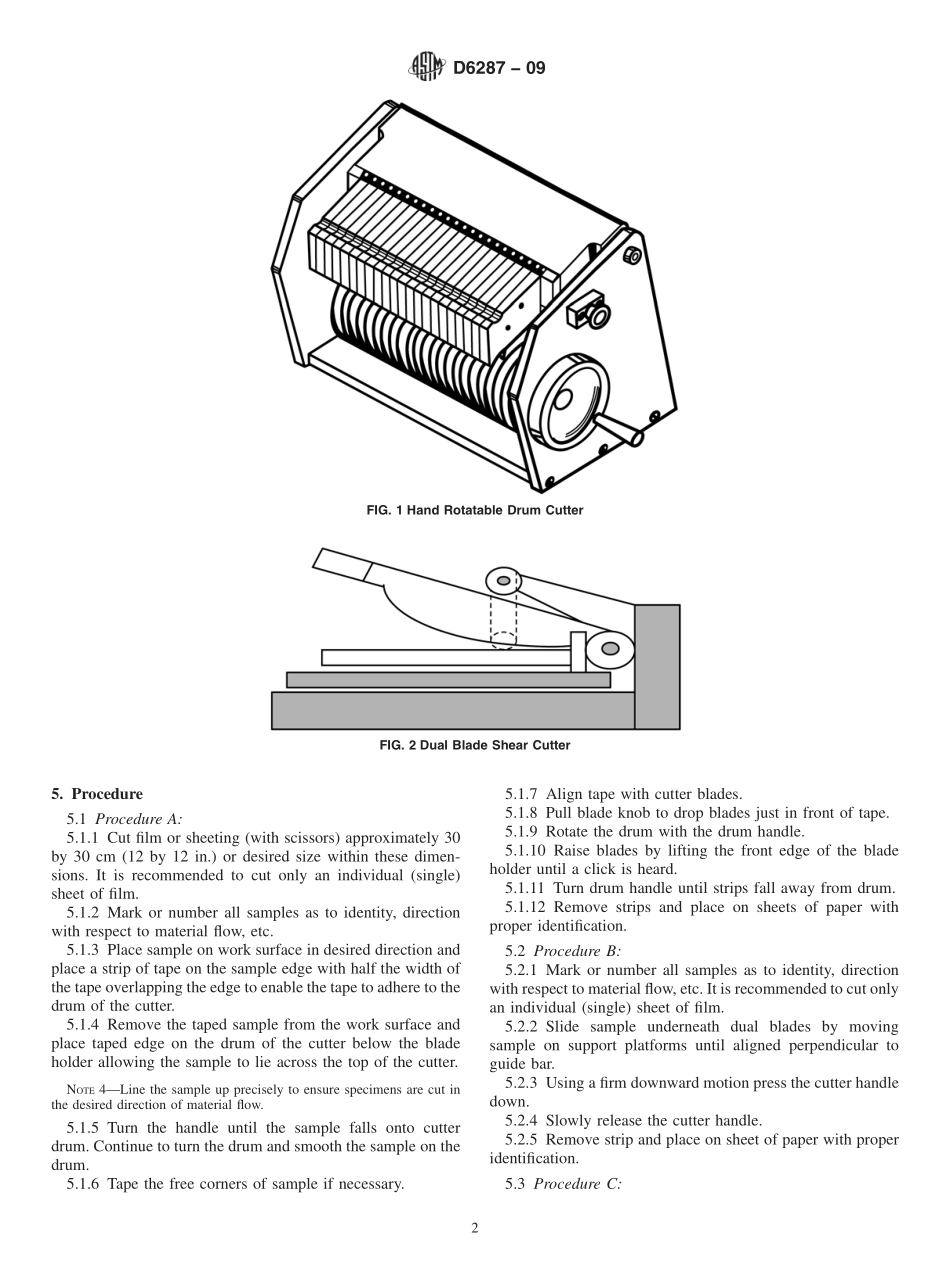

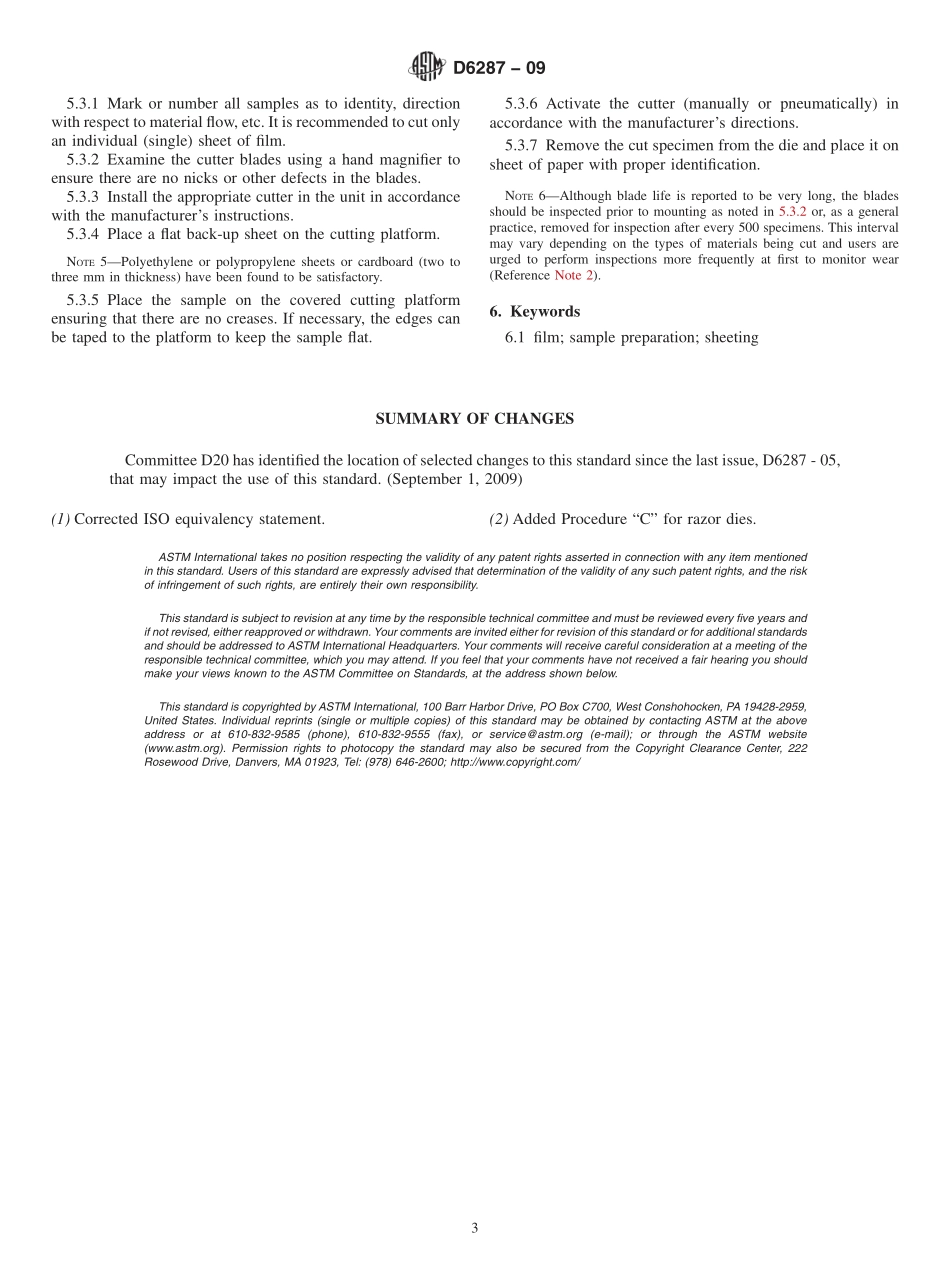

Designation:D6287−09StandardPracticeforCuttingFilmandSheetingTestSpecimens1ThisstandardisissuedunderthefixeddesignationD6287;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thispracticecoversequipmentandtechniquesforcuttingfilmandsheetingspecimensfortesting.2Thespeci-mensarenick-free,non-stretchedandcanberapidlyprepared.1.2ThevaluesgiveninSIunitsaretobeconsideredstandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.NOTE1—ThereisnoknownISOequivalenttothisstandard.2.ReferencedDocuments2.1ASTMStandards:3D882TestMethodforTensilePropertiesofThinPlasticSheetingD2838TestMethodforShrinkTensionandOrientationReleaseStressofPlasticFilmandThinSheetingF88TestMethodforSealStrengthofFlexibleBarrierMaterials3.SignificanceandUse3.1ManytestmethodsincludingTestMethodsD882,D2838,andF88requiretheuseofnarrowstripsofvaryinglength.Thequalityofthesamplepreparationdirectlyaffectstestresults.Thispracticedescribestwotechniquesforprepar-ingsampleswithstraight,clean,paralleledgeswithnovisibleimperfections.NOTE2—Aftercutting,eachspecimenshouldbeexaminedvisuallytoinsuretheedgesareundamaged(freeofnicks).Onaperiodicbasisspecimenedgequalityshouldbeevaluatedbymicroscopicexamination.Todeterminewhencuttingbladesneedtobereplacedorsharpened,acontrolchartoftensilestrengthandpercentelongationatbreak(seeTestMethodD882)ofauniformmaterialmaybemaintained.Tensilestrengthandpercentelongationatbreakwilldecreaseasthequalityofspecimencuttingdecreases.4.ApparatusandMaterials4.1ProcedureA—Ahandrotatabledrumcutter(Fig.1)containinga12.7cm(5in.)diameterdrum...