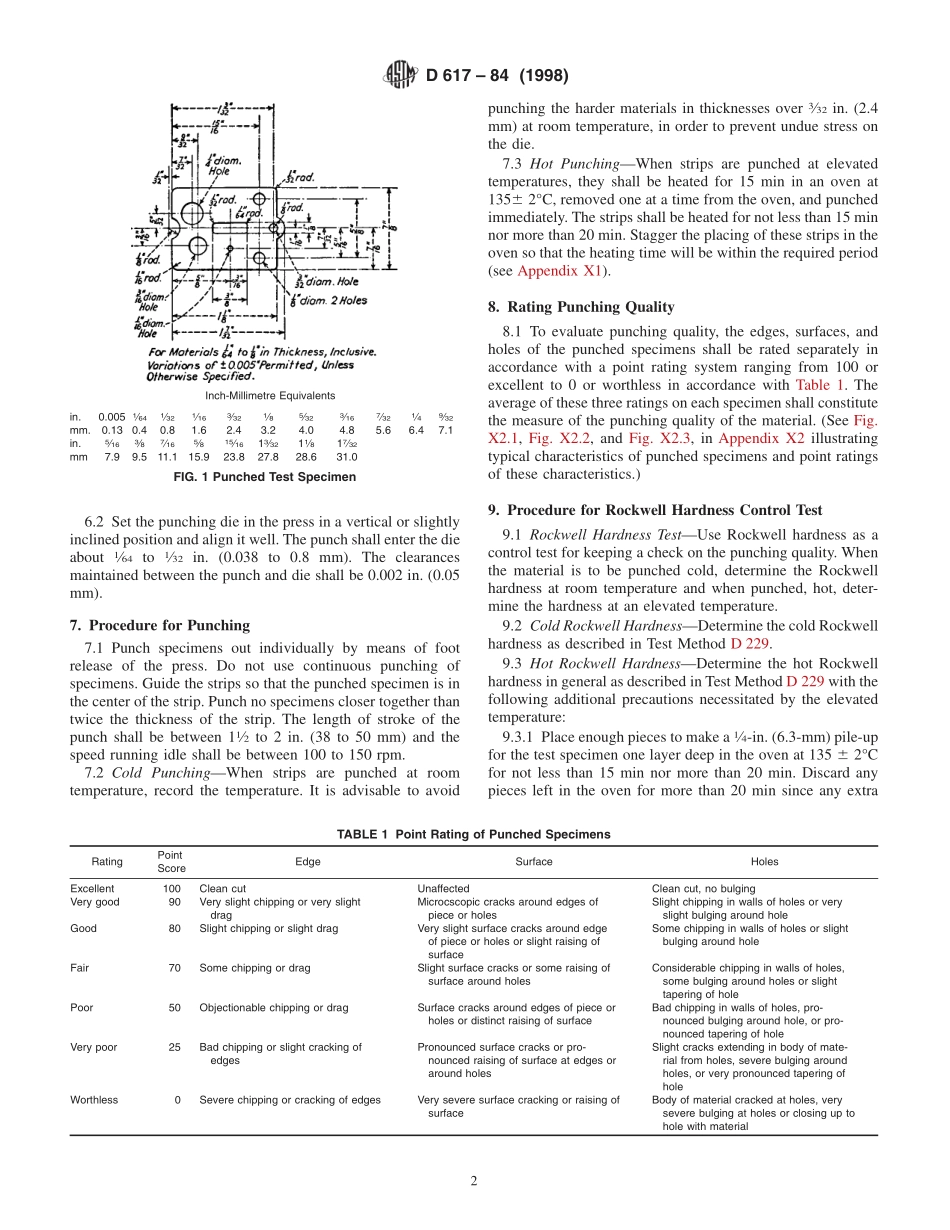

Designation:D617–84(Reapproved1998)AnAmericanNationalStandardStandardTestMethodforPunchingQualityofPhenolicLaminatedSheets1ThisstandardisissuedunderthefixeddesignationD617;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheDepartmentofDefense.1.Scope1.1Thistestmethodcoversthedeterminationofthepunch-ingqualityofphenoliclaminatedsheets1⁄8in.(3.2mm)andunderinthickness.Itinvolvestheuseofastandardpunchingdieandstandardpunchingpracticetoformpunchedspecimensbothatroomtemperature,designatedascoldpunching,andatanelevatedtemperatureof135°C,designatedashotpunching,andastandardsystemforratingthepunchedspecimensproduced.1.2Thevaluesstatedininch-poundunitsaretoberegardedasthestandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:D229TestMethodsforRigidSheetandPlateMaterialsUsedforElectricalInsulation2D785TestMethodforRockwellHardnessofPlasticsandElectricalInsulatingMaterials3E18TestMethodsforRockwellHardnessandRockwellSuperficialHardnessofMetallicMaterials43.SignificanceandUse3.1Thistestmethodfurtherprovidesforacontroltestonuniformityofpunchingqualityafterthispropertyhasbeendeterminedwiththepunchingdieforaparticulargradeandthickness.ThecontroltestconsistsinthedeterminationofRockwellhardnessatroomtemperature,andRockwellhard-nessat135°Cunderadefinitelyprescribedprocedure.54.Apparatus4.1PunchingDie—Acompounddie.64.2Oven—Anoventhatwillprovideatemperatureof13562°C.4.3HardnessTester—ARockwellhardnesstesterconform-ingtotherequirementsprescribedinTestMethodsE18.5.TestSpecimens5.1PunchingTestSpecime...