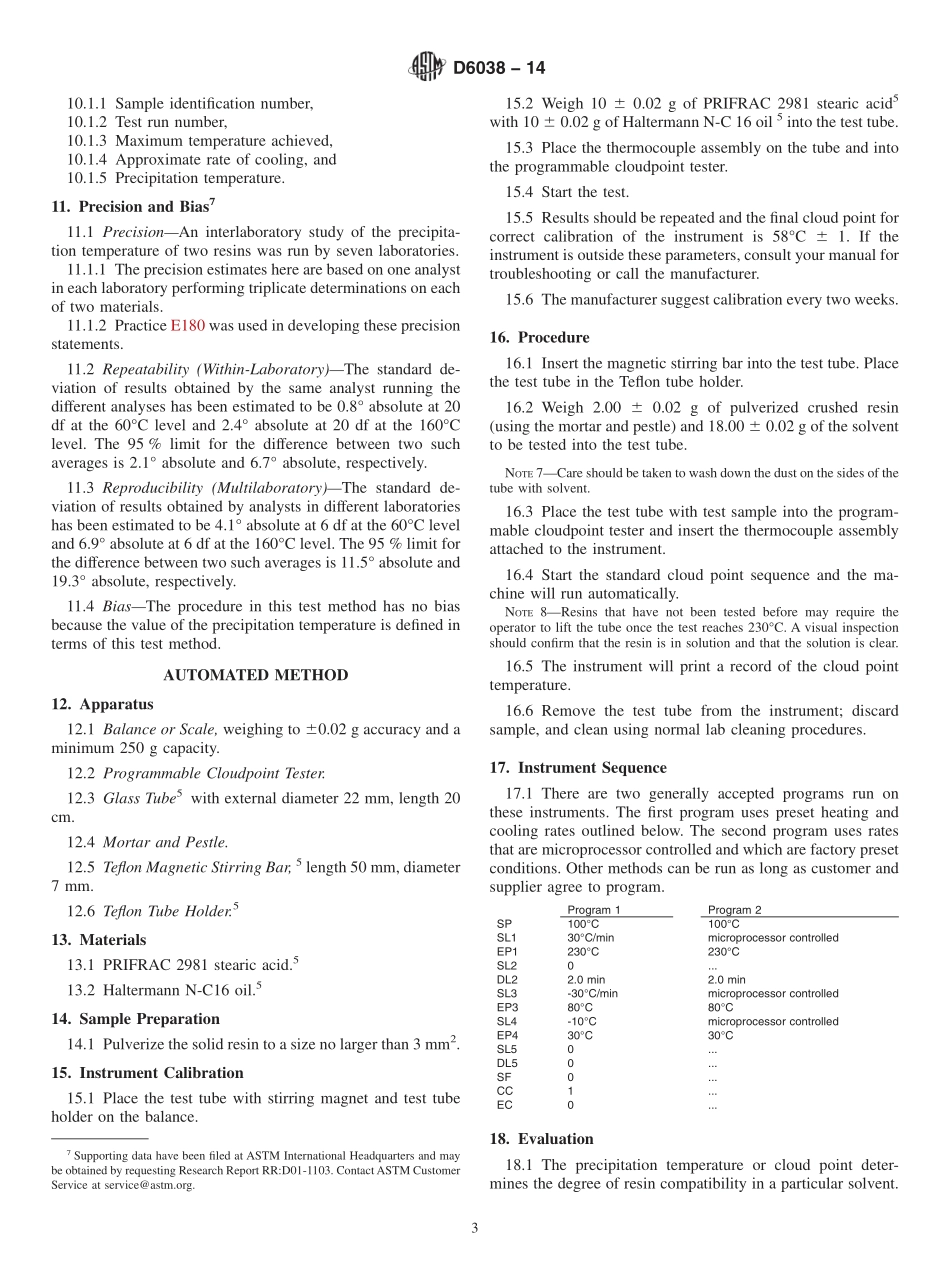

Designation:D6038−14StandardTestMethodsforDeterminingtheCompatibilityofResin/SolventMixturesbyPrecipitationTemperature(CloudPoint)1ThisstandardisissuedunderthefixeddesignationD6038;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thesetestmethodscoverthemanualandautomaticproceduresfortestingthecompatibilityoflithographicinkresinsinhighboilinginksolventsbyprecipitationtemperature(cloudpoint)inarangefrom35to210°C.1.2Themanualprocedureinthistestmethoduseslabora-toryequipmentgenerallyavailableinanormal,well-equippedlaboratory.Theautomatedprocedureusesaprogrammablecloudpointtester.1.3Thistestmethodisforusewithinkresinsintendedmainlyforoil-basedoffsetandletterpressinks.Thetypeofresinsaretypically,butnotlimitedtoC9aromatichydrocarbonresins,modifieddicyclopentadieneresins,rosinpentaerythritolorglycerolesters,phenolicmodifiedrosinesters,maleicanhydridemodified-rosinesters,andnaturallyoccurringresinssuchasgilsonite.1.4Aresinsolutionorinkvehiclecouldalsobeusedinthistestinsteadoftheresin.1.5ThetypicalhighboilingsolventstobeusedareC12toC16petroleumdistillates.1.6Toavoidfireorinjury,orboth,totheoperator,thistestmethodshouldnotbeusedwithlowflashpointsolventssuchastolueneorxylene.Theminimumflashpointofthesolventsusedshouldbe60°CasdeterminedbyTestMethodD56.NOTE1—Usersofthistestmethodshouldbeawarethattheflashpointofmanysolventsusedforthistest(asdefinedinTestMethodsD56andD1310)isexceededintheheatingcycleofthistestmethod.Safetyprecautionsshouldbetakensincethereisthepotentialforvaporignition.Themethodoutlinedshouldbedoneinashieldedexhausthood,wherethereisaccesstoafireextinguisherifneeded.1.7ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.8Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associate...