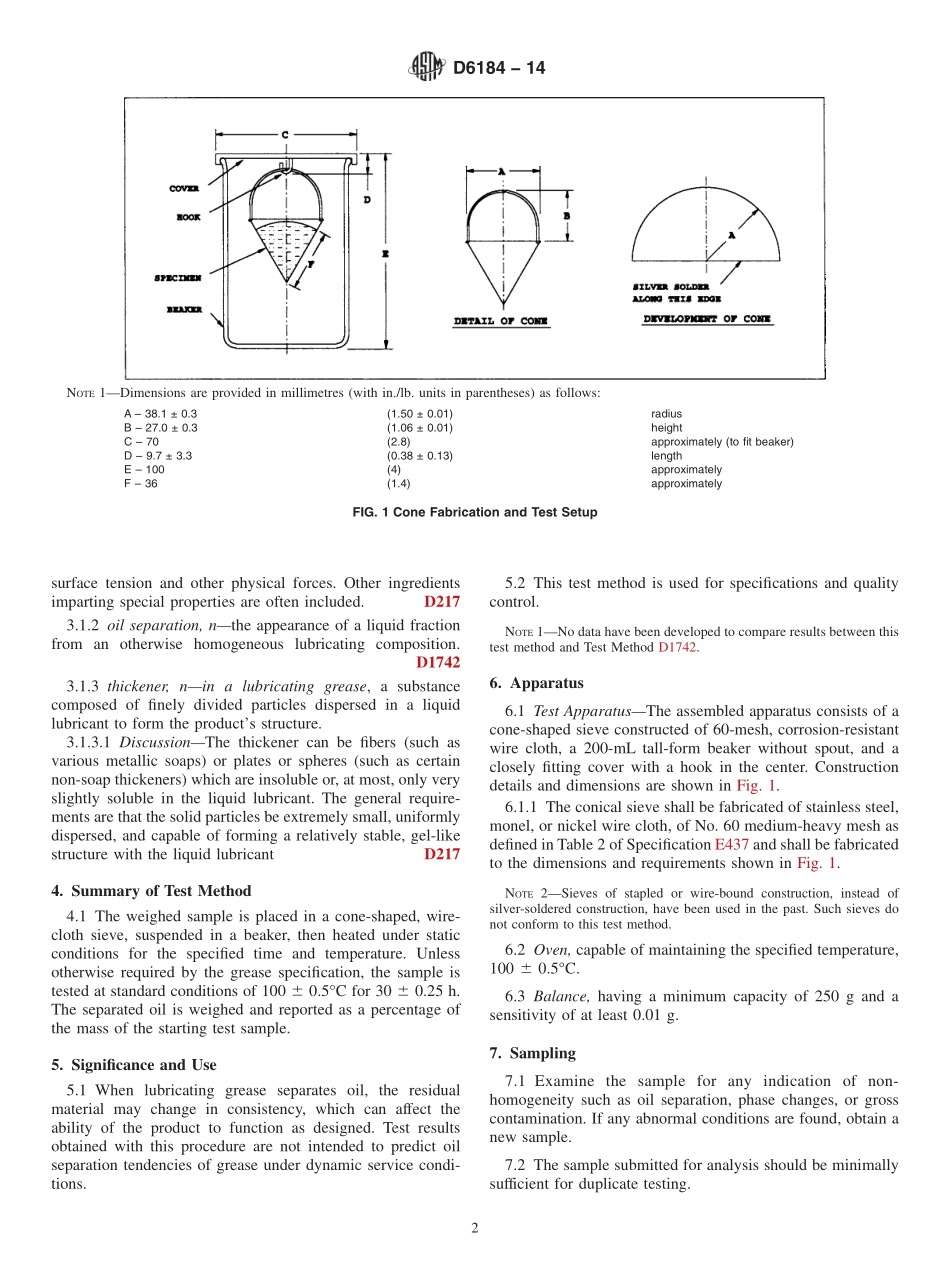

Designation:D6184−14StandardTestMethodforOilSeparationfromLubricatingGrease(ConicalSieveMethod)1ThisstandardisissuedunderthefixeddesignationD6184;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.INTRODUCTIONTheconicalsievemethodformeasuringleakagefromlubricatinggrease(commonlyknownastheconebleedtest)usesthesameequipmentasthenowobsoleteandwithdrawnFederalTestMethod(FTM)791CMethod321.3,OilSeparationfromLubricatingGrease(StaticTechnique).Despitethelackofaprecisionstatement,Method321.3hadbeenusedformanyyearsinmilitaryandindustrialgreasespecificationstodeterminefluidseparationtendenciesfromgreases.TestMethodD6184overcomesthedeficienciesofMethod321.3.ItreflectstheproceduresandprecisiondeterminationsusedinacooperativestudyinSubcommitteeD02.G0ofCommitteeD02andsupersedestheFTMmethod.1.Scope1.1Thistestmethodcoversthedeterminationoftheten-dencyoflubricatinggreasetoseparateoilatanelevatedtemperature.Thistestmethodshallbeconductedat100°Cfor30hunlessotherconditionsarerequiredbythegreasespecification.1.2Thistestmethodissuitableforusewithmostallgreases,butthetestprecisionwasestablishedusinggreaseshavingaworkedpenetration(TestMethodsD217)greaterthan220(NLGINo.3grade)andlessthan340(NLGINo.1grade).1.3ThevaluesstatedinSIunitsaretoberegardedasstandard.Theterm60meshwasoriginallydescribedinthenowwithdrawnE437standard.Itisusedtodescribethewiremeshbecausethereisnoexactmetricequivalent.1.4Thisstandarddoesnotpurporttoaddressallthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafetypracticesanddeterminetheapplicabilityofregulatorylimita-tionspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D217TestMethodsforConePenetrationofLubricatingGreaseD1742TestMe...