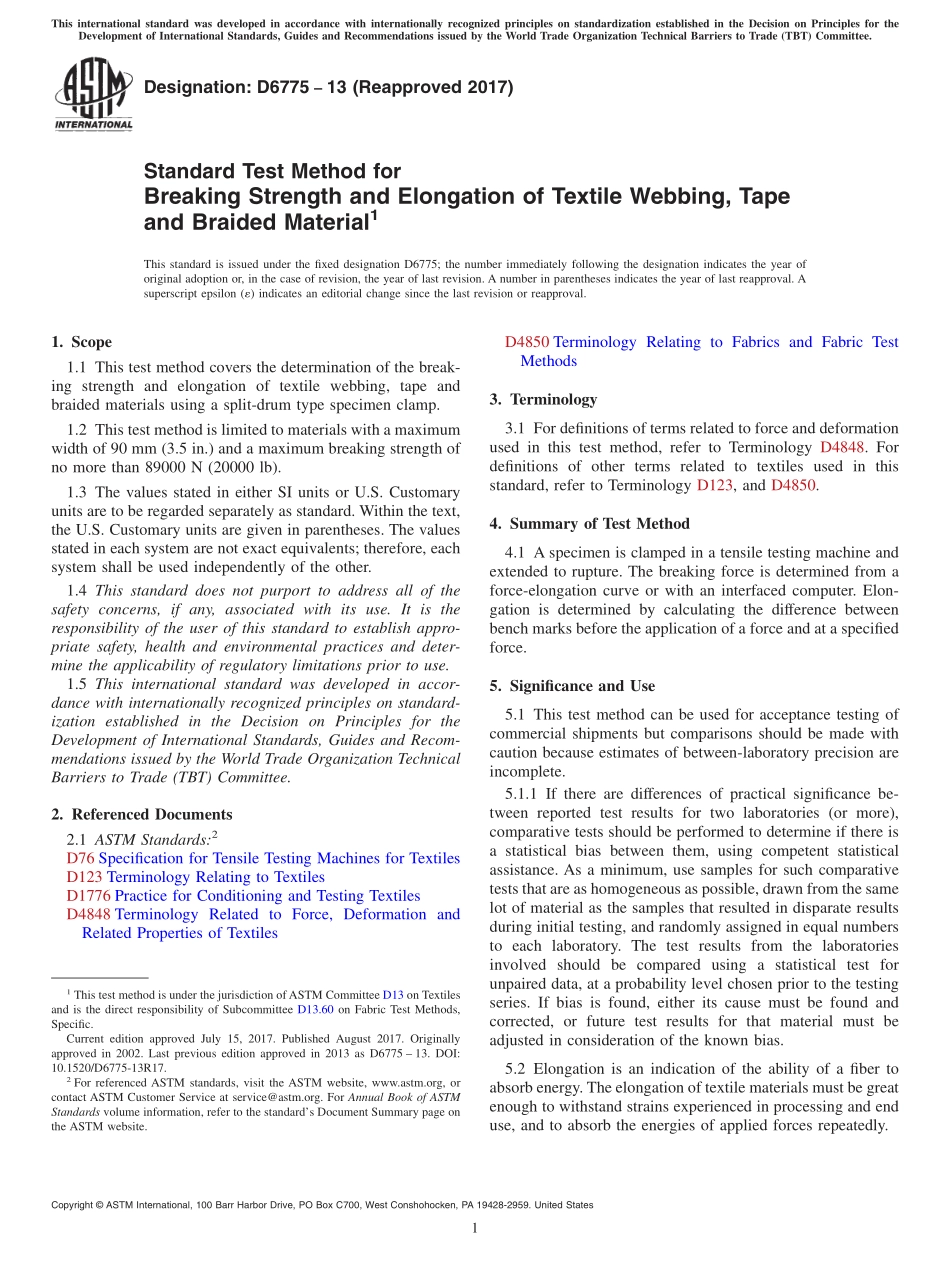

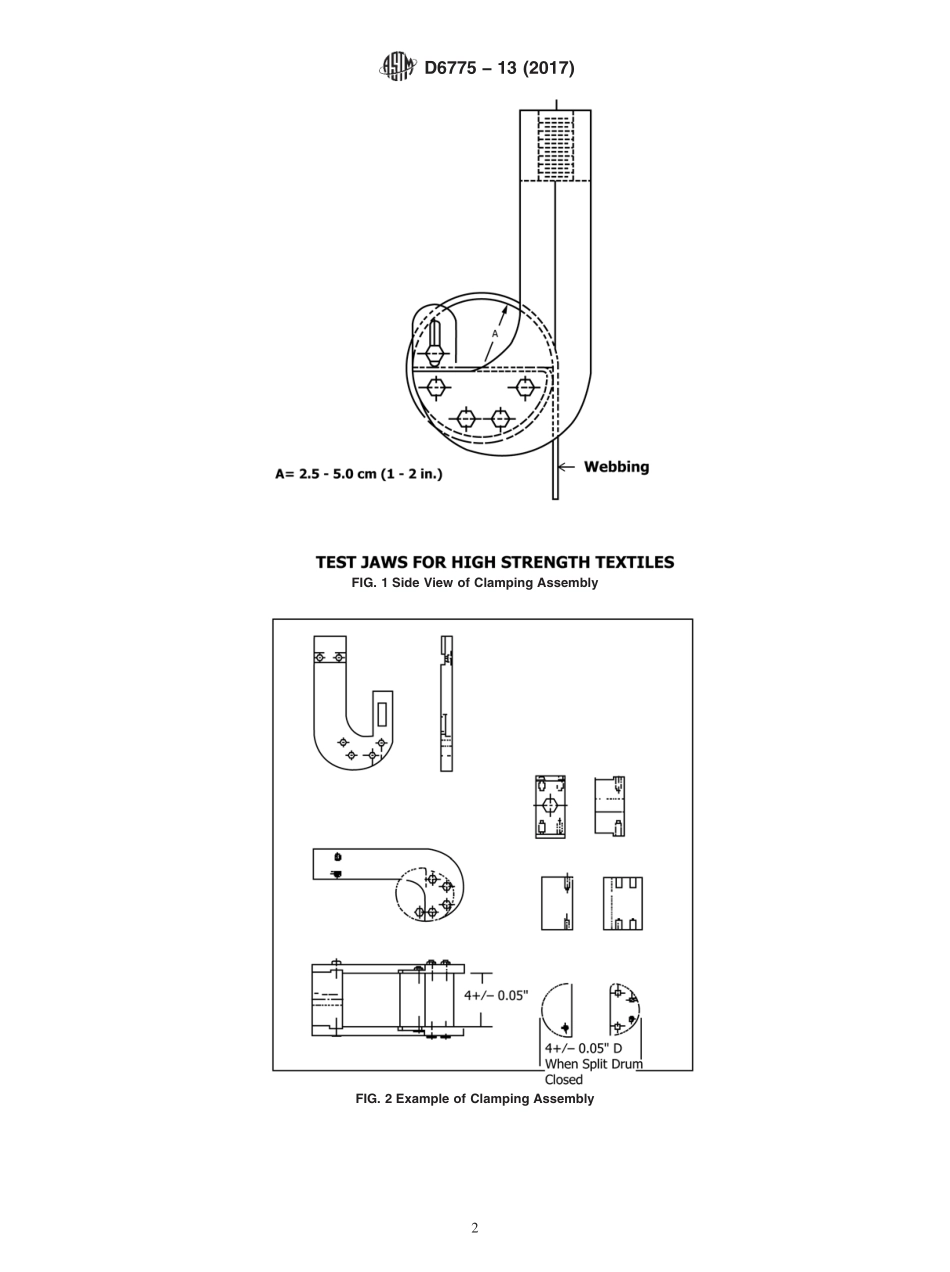

Designation:D6775−13(Reapproved2017)StandardTestMethodforBreakingStrengthandElongationofTextileWebbing,TapeandBraidedMaterial1ThisstandardisissuedunderthefixeddesignationD6775;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthedeterminationofthebreak-ingstrengthandelongationoftextilewebbing,tapeandbraidedmaterialsusingasplit-drumtypespecimenclamp.1.2Thistestmethodislimitedtomaterialswithamaximumwidthof90mm(3.5in.)andamaximumbreakingstrengthofnomorethan89000N(20000lb).1.3ThevaluesstatedineitherSIunitsorU.S.Customaryunitsaretoberegardedseparatelyasstandard.Withinthetext,theU.S.Customaryunitsaregiveninparentheses.Thevaluesstatedineachsystemarenotexactequivalents;therefore,eachsystemshallbeusedindependentlyoftheother.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,healthandenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.1.5Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D76SpecificationforTensileTestingMachinesforTextilesD123TerminologyRelatingtoTextilesD1776PracticeforConditioningandTestingTextilesD4848TerminologyRelatedtoForce,DeformationandRelatedPropertiesofTextilesD4850TerminologyRelatingtoFabricsandFabricTestMethods3.Terminology3.1Fordefinitionsoftermsrelatedtoforceanddeformationusedinthistestmethod,refertoTerminologyD4848.Fordefinitionsofothertermsrelatedtotextilesusedinthisstandard,refertoTerminologyD123,and...