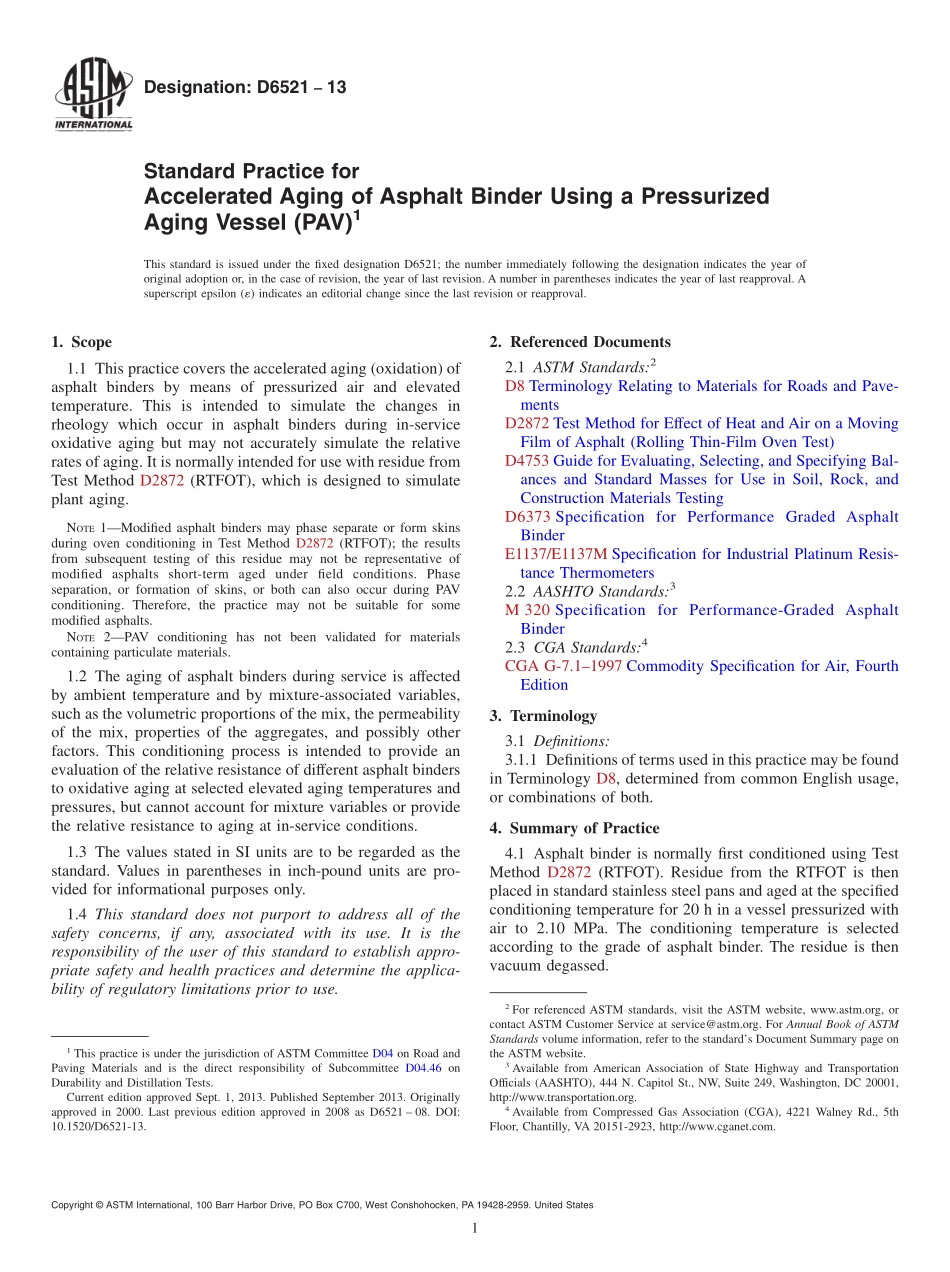

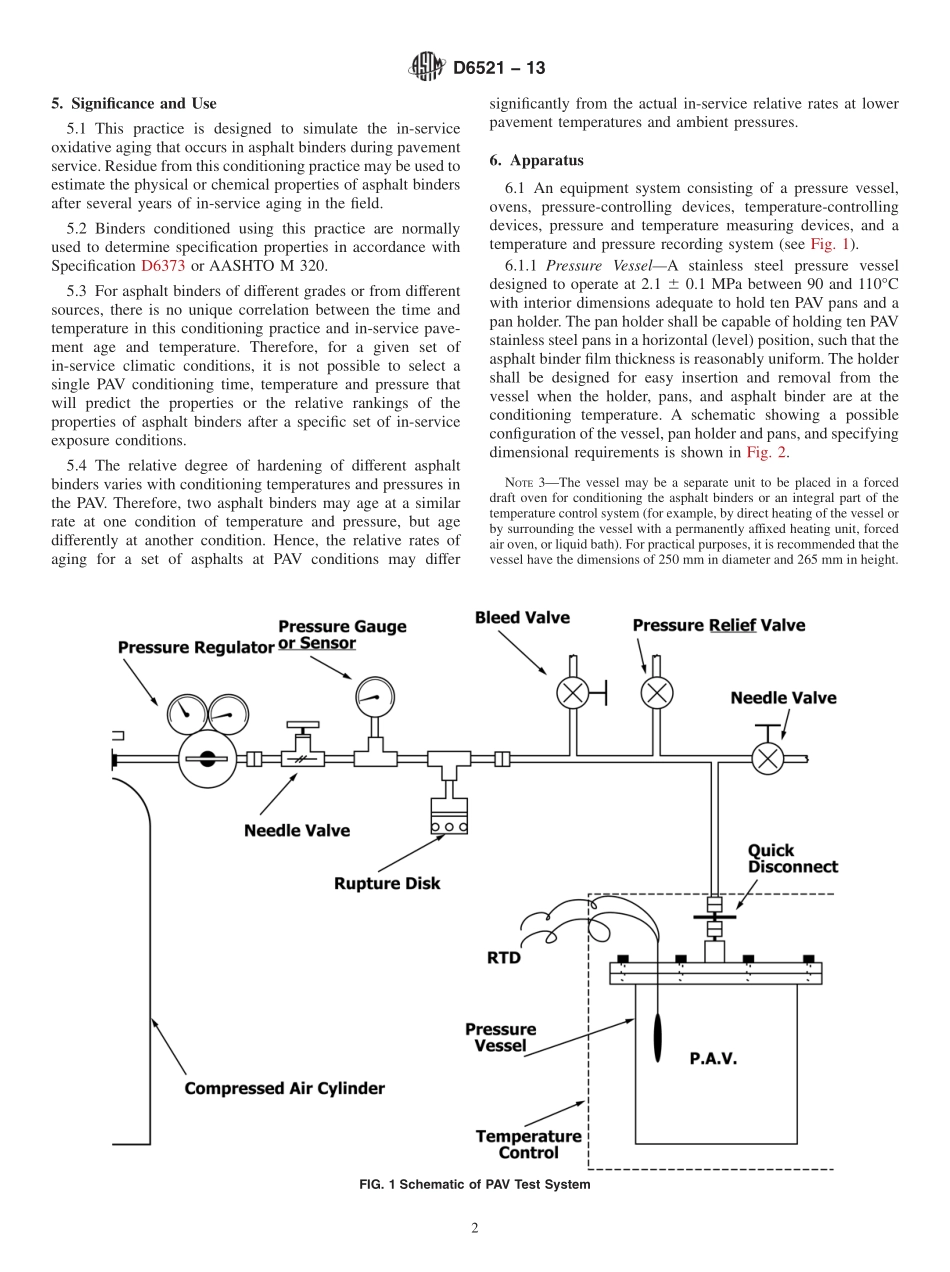

Designation:D6521−13StandardPracticeforAcceleratedAgingofAsphaltBinderUsingaPressurizedAgingVessel(PAV)1ThisstandardisissuedunderthefixeddesignationD6521;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thispracticecoverstheacceleratedaging(oxidation)ofasphaltbindersbymeansofpressurizedairandelevatedtemperature.Thisisintendedtosimulatethechangesinrheologywhichoccurinasphaltbindersduringin-serviceoxidativeagingbutmaynotaccuratelysimulatetherelativeratesofaging.ItisnormallyintendedforusewithresiduefromTestMethodD2872(RTFOT),whichisdesignedtosimulateplantaging.NOTE1—ModifiedasphaltbindersmayphaseseparateorformskinsduringovenconditioninginTestMethodD2872(RTFOT);theresultsfromsubsequenttestingofthisresiduemaynotberepresentativeofmodifiedasphaltsshort-termagedunderfieldconditions.Phaseseparation,orformationofskins,orbothcanalsooccurduringPAVconditioning.Therefore,thepracticemaynotbesuitableforsomemodifiedasphalts.NOTE2—PAVconditioninghasnotbeenvalidatedformaterialscontainingparticulatematerials.1.2Theagingofasphaltbindersduringserviceisaffectedbyambienttemperatureandbymixture-associatedvariables,suchasthevolumetricproportionsofthemix,thepermeabilityofthemix,propertiesoftheaggregates,andpossiblyotherfactors.Thisconditioningprocessisintendedtoprovideanevaluationoftherelativeresistanceofdifferentasphaltbinderstooxidativeagingatselectedelevatedagingtemperaturesandpressures,butcannotaccountformixturevariablesorprovidetherelativeresistancetoagingatin-serviceconditions.1.3ThevaluesstatedinSIunitsaretoberegardedasthestandard.Valuesinparenthesesininch-poundunitsarepro-videdforinformationalpurposesonly.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetya...