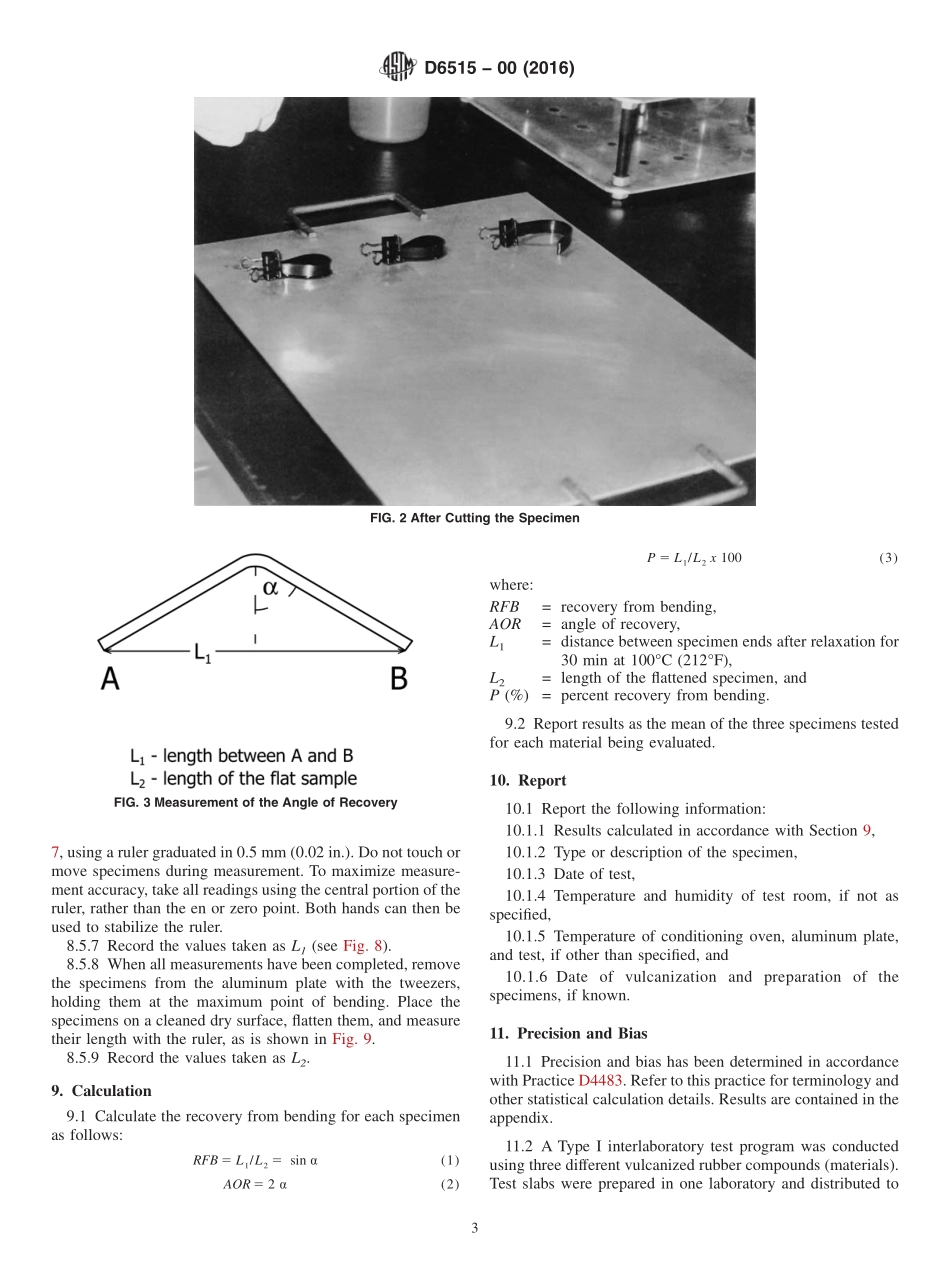

Designation:D6515−00(Reapproved2016)StandardTestMethodforRubberShaftSealsDeterminationofRecoveryFromBending1ThisstandardisissuedunderthefixeddesignationD6515;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversaproceduretodeterminetherecoveryresponseofrubberafterparticularbendingdeformation,subsequenttoaginginselectedmediaataspecifiedtemperature,andforaspecifiedtimeperiod,thusprovidingameasureoftherelativeperformancepotentialofcompoundsusedinthemanufactureofshaftseals.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D412TestMethodsforVulcanizedRubberandThermoplas-ticElastomers—TensionD471TestMethodforRubberProperty—EffectofLiquidsD1349PracticeforRubber—StandardConditionsforTest-ingD3183PracticeforRubber—PreparationofPiecesforTestPurposesfromProductsD4483PracticeforEvaluatingPrecisionforTestMethodStandardsintheRubberandCarbonBlackManufacturingIndustries3.SummaryofTestMethod3.1Theendsofrectangularspecimensofcandidateshaftsealcompoundsareclippedtogetherandthespecimensex-posedunderspecifiedconditionsoftimeandtemperatureinafluidenvironmentthatbestsimulatesanticipatedoperatingconditions.Uponcompletionoftheexposure,theclampsareremovedandthespecimenareallowedtorecoverfrombending.Afteraspecifiedperiodoftime,thedistancebetweenendsofthespecimensismeasuredandtheamountofrecoverycalculated.4.SignificanceandUse4.1Amongthefactorsaffectingshaftseallifearetheabilitytoretainelasticityandcompensateforshafteccentricit...