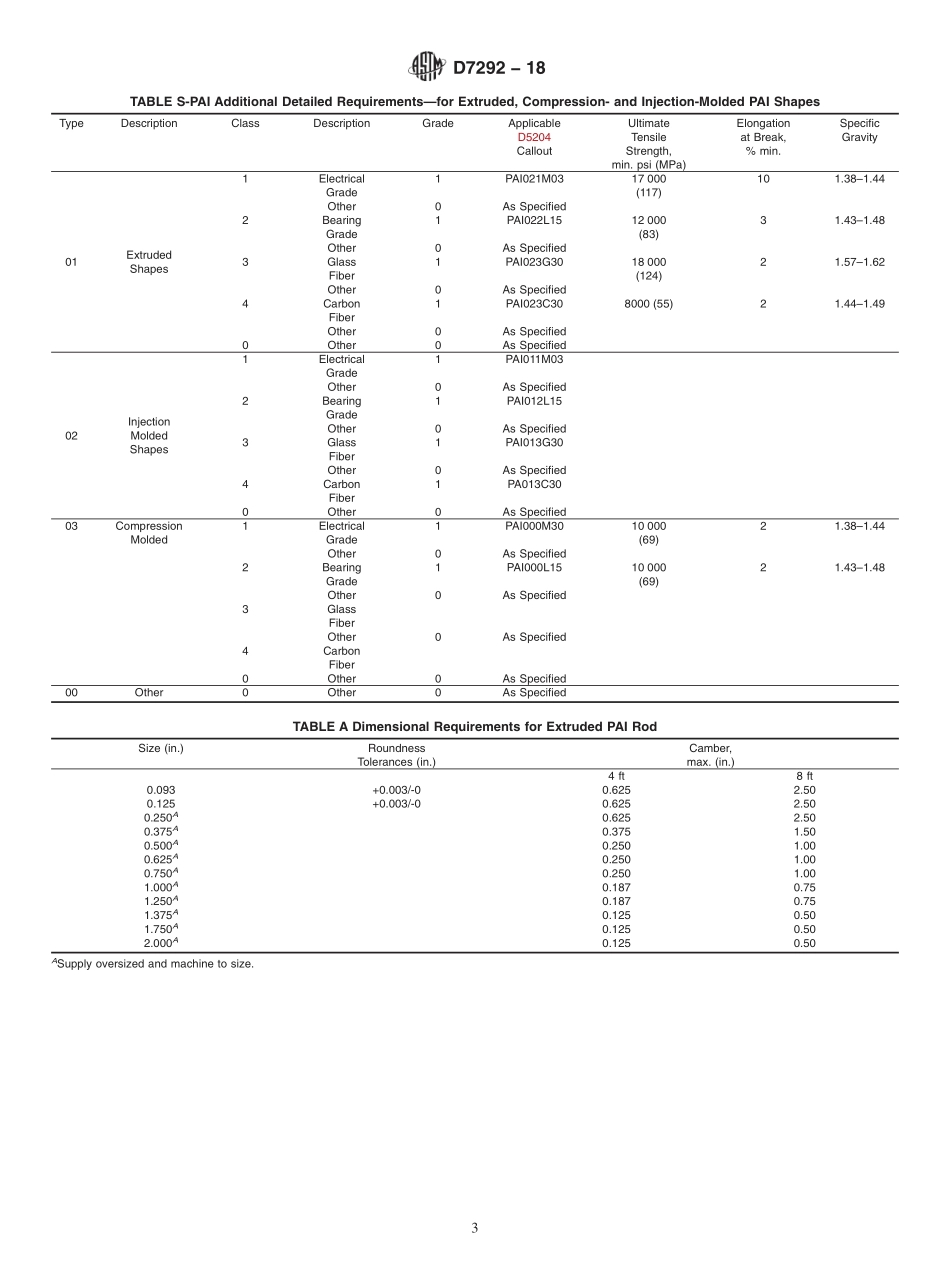

Designation:D7292−18StandardSpecificationforExtruded,Compression-Molded,andInjection-MoldedBasicShapesofPolyamide-Imide(PAI)1ThisstandardisissuedunderthefixeddesignationD7292;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thisspecificationcoversrequirementsandmethodsoftestforthematerial,dimensions,andworkmanshipofextruded,compressionmolded,andinjectionmoldedpartsmanufacturedfromPAI.1.2Thepropertiesincludedinthisspecificationarethoserequiredforthecompositionscovered.Requirementsneces-sarytoidentifyparticularcharacteristicsimportanttospecial-izedapplicationsaredescribedbytheclassificationsystemgiveninSection5.1.3Thisspecificationallowsfortheuseofrecycledmate-rialsprovidedthatspecificationrequirementsbaseduponthisspecificationaremet.1.4ThevaluesstatedinEnglishunitsaretoberegardedasstandardinallpropertyanddimensionaltables.Forreferencepurposes,SIunitsandconversionfactorsarealsoincluded.1.5ThefollowingprecautionarycaveatpertainsonlytothetestmethodportionSection12,ofthisspecification.Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafety,health,andenvironmentalpracticesanddeterminetheapplicabilityofregulatorylimitationspriortouse.NOTE1—ThereisnoknownISOequivalenttothisstandard.1.6Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D256TestMethodsforDeterminingtheIzodPendulumImpactResistanceofPlasticsD618PracticeforConditioningPlasticsforTestingD638TestMethodforTensilePropertiesofPlasti...