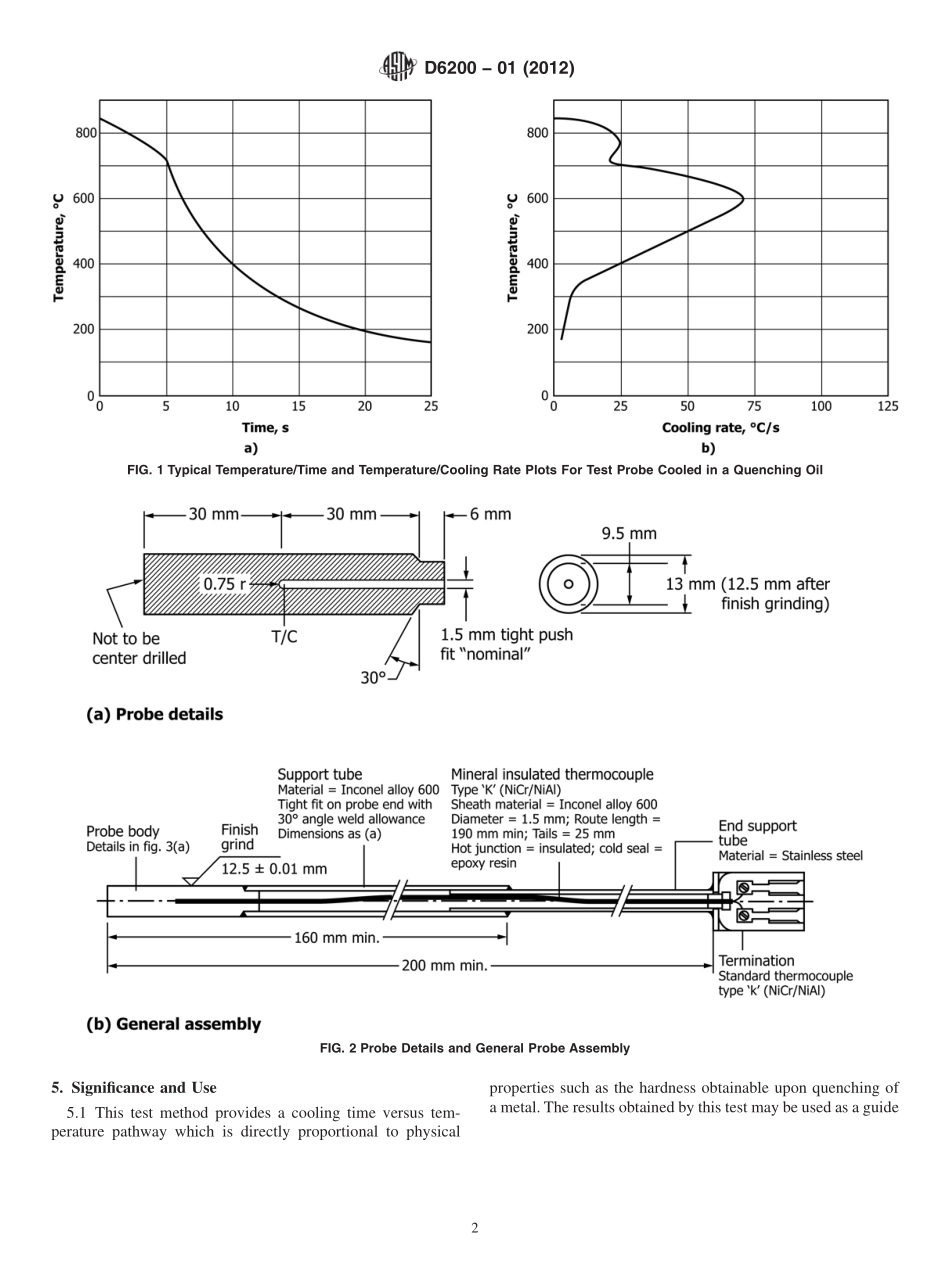

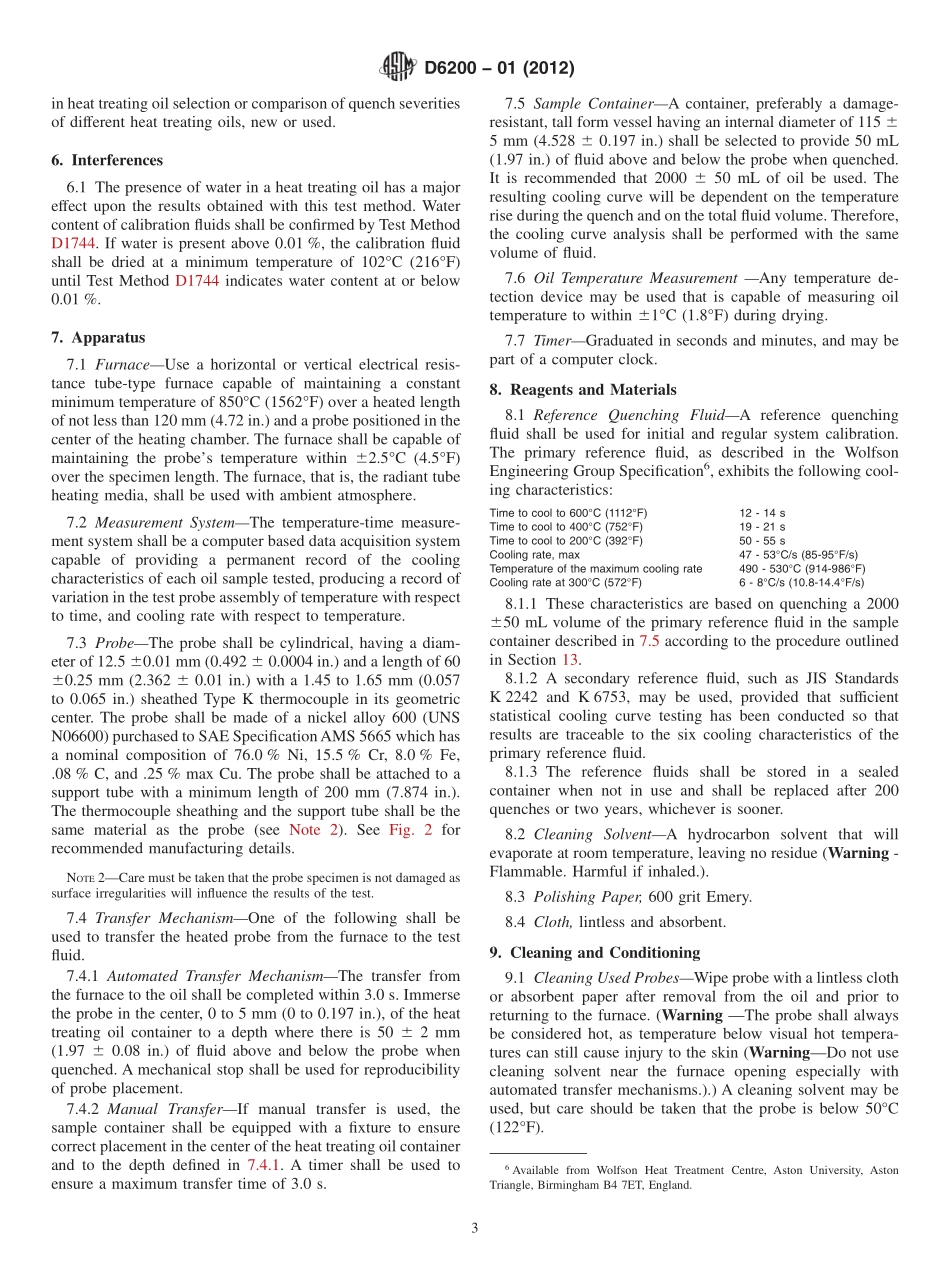

Designation:D6200−01(Reapproved2012)StandardTestMethodforDeterminationofCoolingCharacteristicsofQuenchOilsbyCoolingCurveAnalysis1ThisstandardisissuedunderthefixeddesignationD6200;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethoddescribestheequipmentandtheprocedureforevaluationofaquenchingoil’squenchingcharacteristicsbycoolingratedetermination.1.2Thistestisdesignedtoevaluatequenchingoilsinanon-agitatedsystem.Thereisnocorrelationbetweenthesetestresultsandtheresultsobtainedinagitatedsystems.1.3ThevaluesinSIunitsaretoberegardedasthestandard.Thevaluesinparenthesesareprovidedforinformationonly.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D1744TestMethodforDeterminationofWaterinLiquidPetroleumProductsbyKarlFischerReagentE220TestMethodforCalibrationofThermocouplesByComparisonTechniquesE230SpecificationandTemperature-ElectromotiveForce(EMF)TablesforStandardizedThermocouples2.2SAEStandards:3AMS5665NickelAlloyCorrosionandHeatResistantBars,ForgingsandRings2.3JapaneseIndustrialStandards(JIS):4JISK2242-1980HeatTreatingOilJISK6753-1977Di-2-ethylhexylPhthalate3.Terminology3.1DefinitionsofTermsSpecifictoThisStandard:3.1.1coolingcurve,n—thecoolingcurveisagraphicalrepresentationofthecoolingtime(t)-temperature(T)re-sponseoftheprobe(see7.3).AnexampleisillustratedinPartBofFig.1.3.1.2coolingcurveanalysis,n—theprocessofquantifyingthecoolingcharacteristicsofaheattreatingoilbasedonthetemperatureversustimeprofileobtainedbycoolingapre-heatedmetalprobeassembly(seeFig.2)understandardconditions.3.1.3coolingratecurve,n—Thecoolingr...