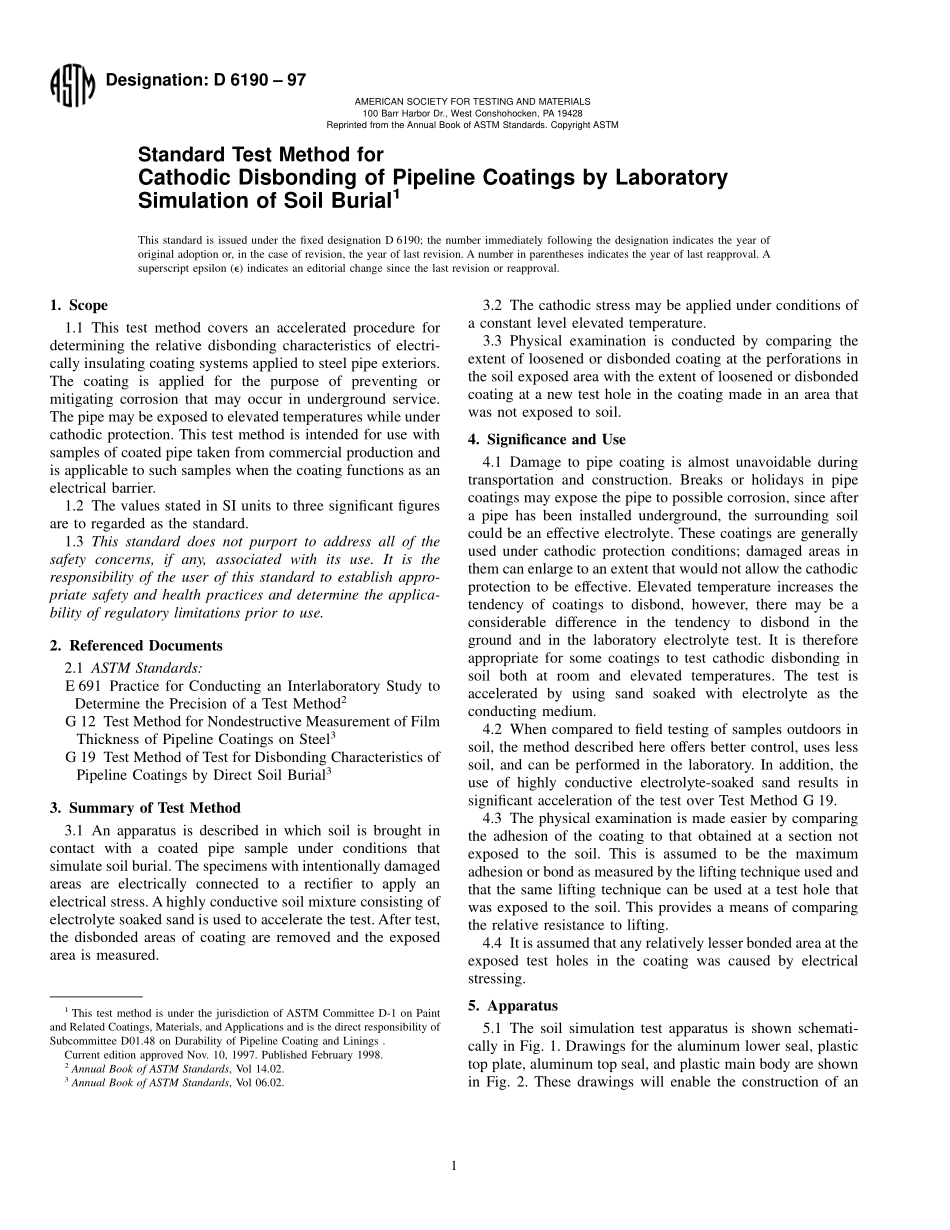

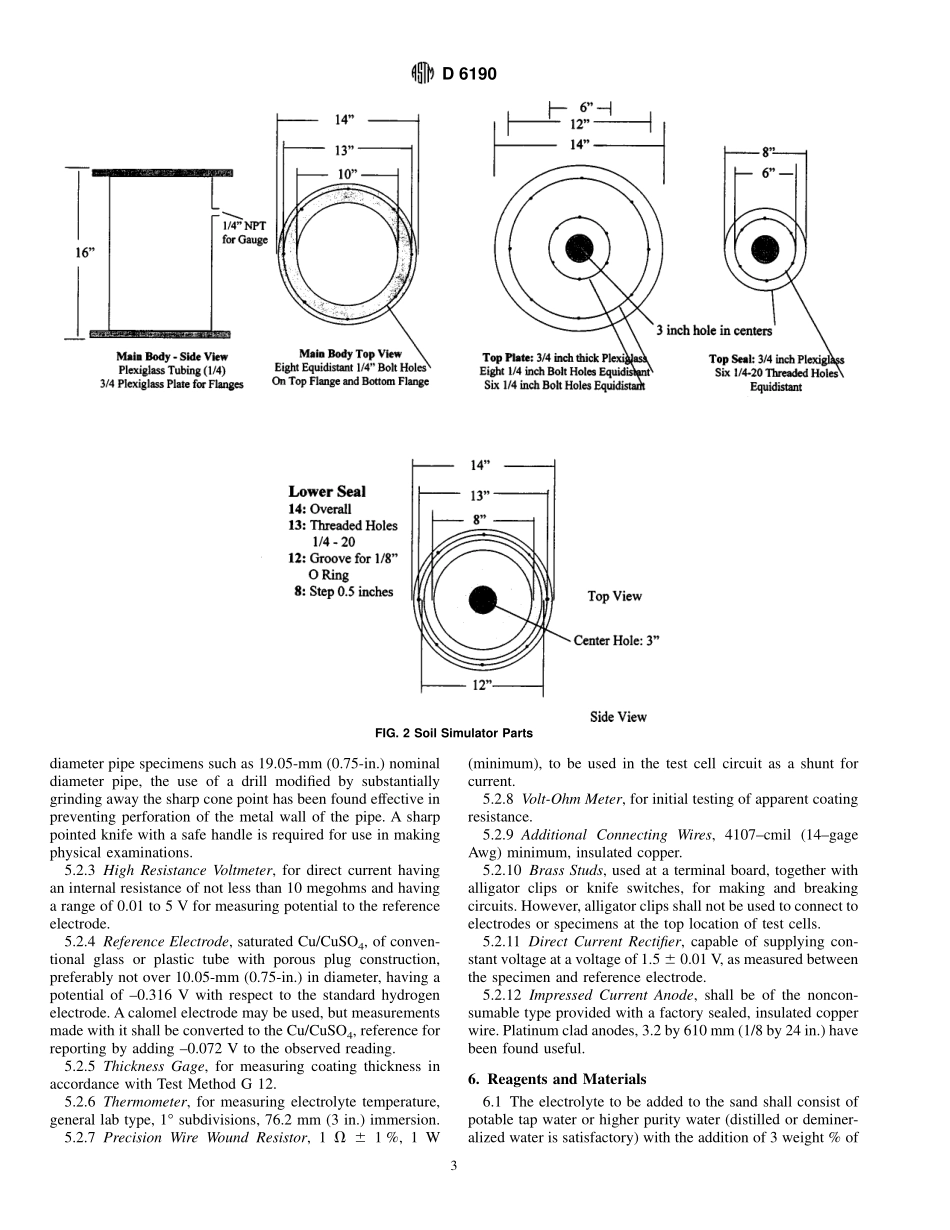

Designation:D6190–97StandardTestMethodforCathodicDisbondingofPipelineCoatingsbyLaboratorySimulationofSoilBurial1ThisstandardisissuedunderthefixeddesignationD6190;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversanacceleratedprocedurefordeterminingtherelativedisbondingcharacteristicsofelectri-callyinsulatingcoatingsystemsappliedtosteelpipeexteriors.Thecoatingisappliedforthepurposeofpreventingormitigatingcorrosionthatmayoccurinundergroundservice.Thepipemaybeexposedtoelevatedtemperatureswhileundercathodicprotection.Thistestmethodisintendedforusewithsamplesofcoatedpipetakenfromcommercialproductionandisapplicabletosuchsampleswhenthecoatingfunctionsasanelectricalbarrier.1.2ThevaluesstatedinSIunitstothreesignificantfiguresaretoregardedasthestandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:E691PracticeforConductinganInterlaboratoryStudytoDeterminethePrecisionofaTestMethod2G12TestMethodforNondestructiveMeasurementofFilmThicknessofPipelineCoatingsonSteel3G19TestMethodofTestforDisbondingCharacteristicsofPipelineCoatingsbyDirectSoilBurial33.SummaryofTestMethod3.1Anapparatusisdescribedinwhichsoilisbroughtincontactwithacoatedpipesampleunderconditionsthatsimulatesoilburial.Thespecimenswithintentionallydamagedareasareelectricallyconnectedtoarectifiertoapplyanelectricalstress.Ahighlyconductivesoilmixtureconsistingofelectrolytesoakedsandisusedtoacceleratethetest.Aftertest,thedisbondedareasofcoatingareremovedandtheexposedareaismeasured.3.2Thecathodicstressmaybeappliedunderconditionsofaconstantlevelelevatedtemperat...