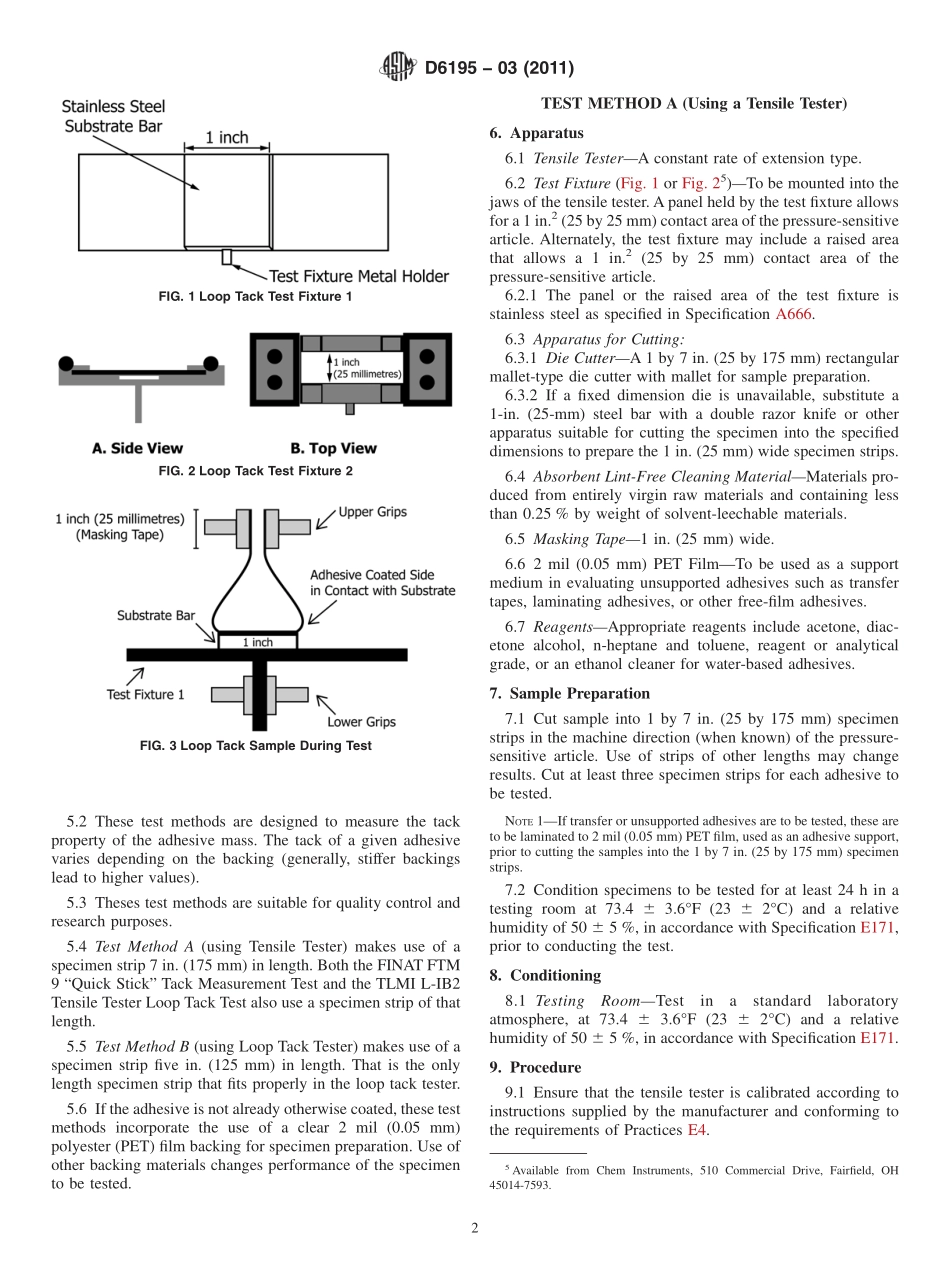

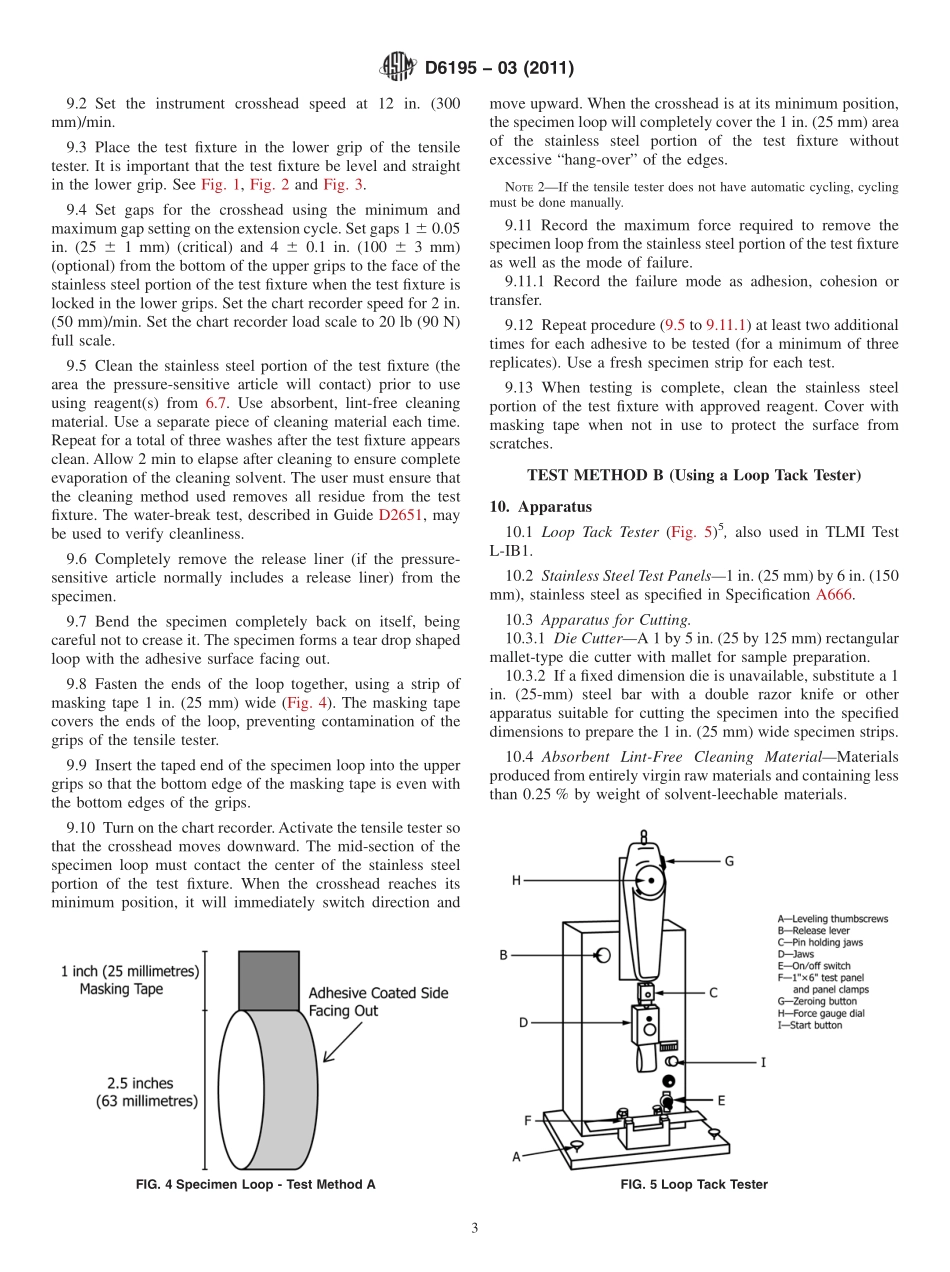

Designation:D6195−03(Reapproved2011)StandardTestMethodsforLoopTack1ThisstandardisissuedunderthefixeddesignationD6195;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thesetestmethodscoverthedeterminationofproper-tiesofapressure-sensitiveadhesive.Thesetestmethodsareapplicabletothoseadhesivesthatformabondofmeasurablestrengthrapidlyuponcontactwithanothersurface.Tackforcemaybemeasuredastheforcerequiredtoseparatetheadhesivefromtheadherendattheinterfaceshortlyaftertheyhavebeenbroughtintocontactunderaloadequalonlytotheweightofthepressure-sensitivearticle(forexample,tape,label,sticker,etc.)ona1in.2contactarea.1.2Thefollowingtestmethodsareincluded:1.2.1TestMethodA(usingTensileTester),and1.2.2TestMethodB(usingLoopTackTester).1.3Thevaluesstatedininch-poundunitsaretoberegardedasthestandardbecausetheindustrystandardwidthforpressure-sensitivetapeis1inch.Thevaluesgiveninparen-thesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2A666SpecificationforAnnealedorCold-WorkedAusteniticStainlessSteelSheet,Strip,Plate,andFlatBarD907TerminologyofAdhesivesD2651GuideforPreparationofMetalSurfacesforAdhesiveBondingE4PracticesforForceVerificationofTestingMachinesE171PracticeforConditioningandTestingFlexibleBarrierPackagingE177PracticeforUseoftheTermsPrecisionandBiasinASTMTestMethodsE691PracticeforConductinganInterlaboratoryStudytoDeterminethePrecisionofaTestMethod2.2EuropeanAssociationforthePre-AdhesedLabelingIndustry(FINAT)Standard:3FTM9“Quick-Stick”T...