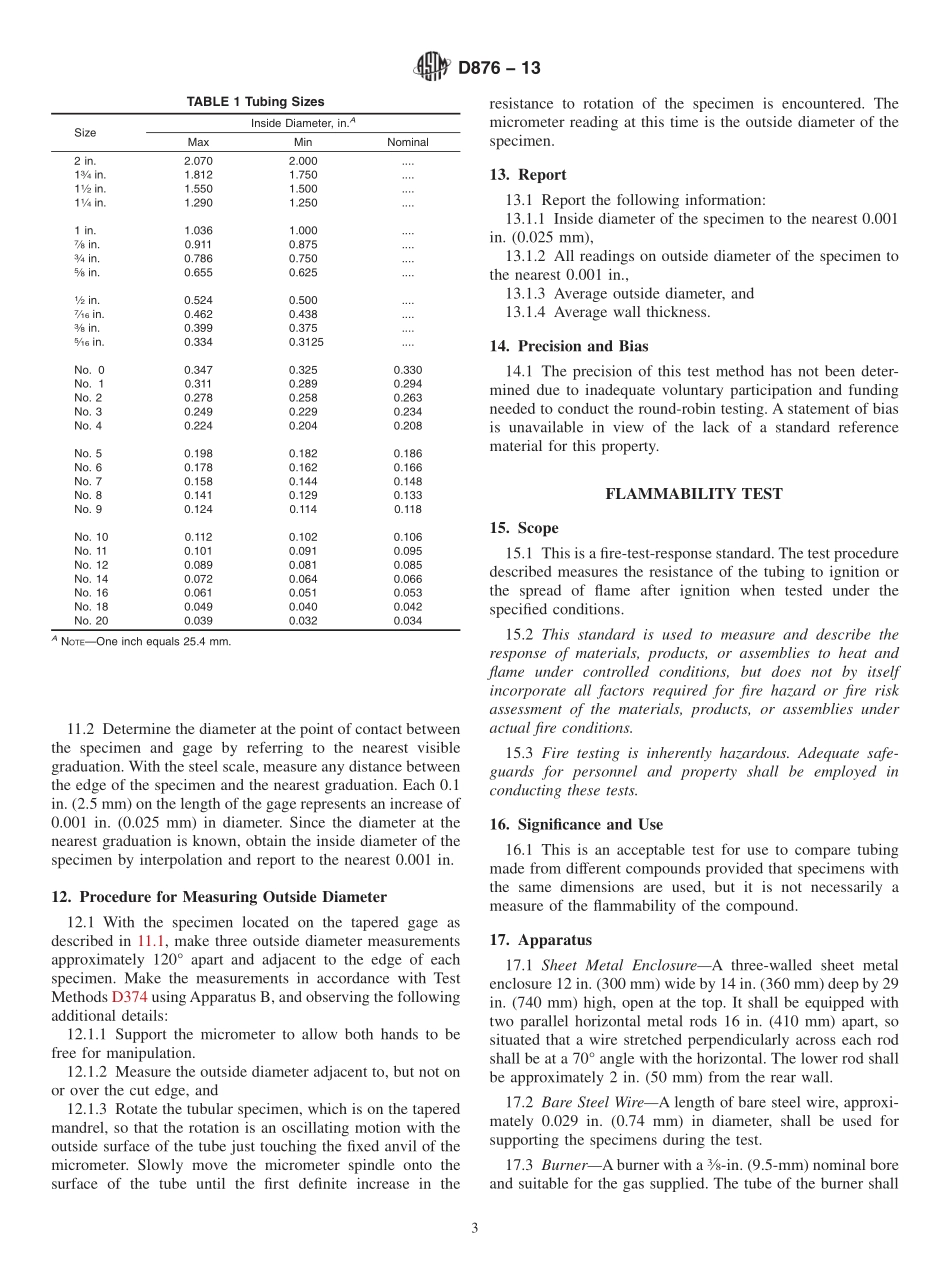

Designation:D876−13StandardTestMethodsforNonrigidVinylChloridePolymerTubingUsedforElectricalInsulation1ThisstandardisissuedunderthefixeddesignationD876;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope*1.1Thesetestmethodscoverthetestingofgeneral-purpose(GradeA),low-temperature(GradeB),andhigh-temperature(GradeC)2nonrigidvinylchloridepolymertubing,oritscopolymerswithothermaterials,foruseaselectricalinsula-tion.Forthepurposeofthesetestmethodsnonrigidtubingshallbetubinghavinganinitialelongationinexcessof100%atbreak.NOTE1—ThesetestmethodsaresimilarbutnotidenticaltothoseinIEC60684–2.1.2Thevaluesstatedininch-poundunitsaretoberegardedasstandard,exceptfortemperature,whichshallbeexpressedindegreesCelsius.ThevaluesgiveninparenthesesaremathematicalconversionstoSIunitsthatareprovidedforinformationonlyandarenotconsideredstandard.1.3Theproceduresappearinthefollowingsections:ProcedureSectionASTMReferenceStandardBrittlenessTemperature43–45D746CorrosionTests74–85D1000DielectricBreakdownVoltageatHighHumidity65–73E104DielectricBreakdownVoltage58–64D149DimensionalTests8–14D374EffectofElevatedTemperatures25–36D412FlammabilityTest15–21OilResistanceTest35–42D471PenetrationTest46–51Sampling6StrainReliefTest68–73TensionTest22–24D412TestConditions7VolumeResistivity52–57D2571.4Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.Forspecifichazardstatements,seeSection5.1.5Forfiretestcaveats,seeSection15.2.ReferencedDocuments2.1ASTMStandards:3D149TestMethodforDielectricBreakdownVoltageandDielectricStrengthofSolid...