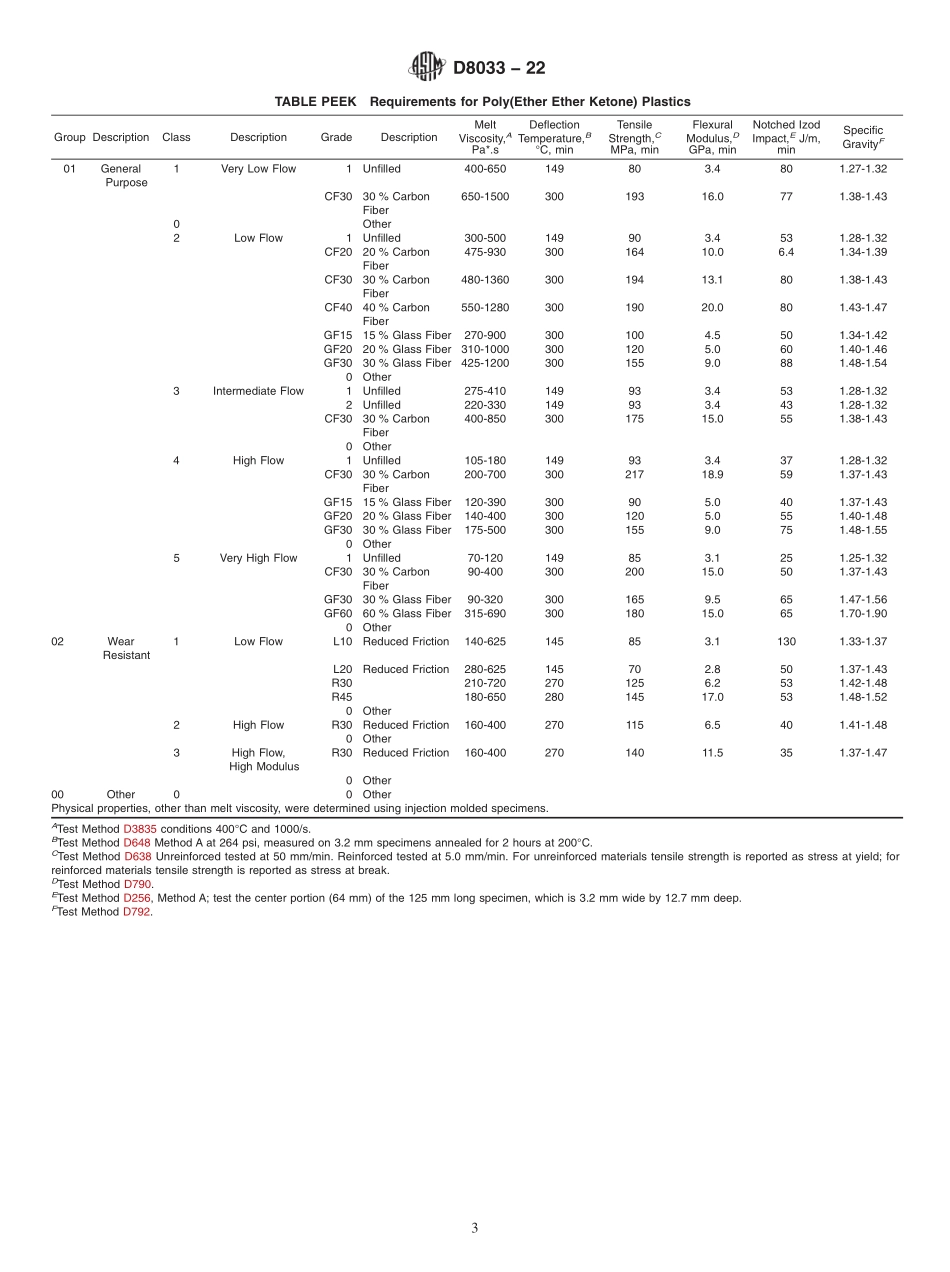

Designation:D8033−22StandardClassificationSystemforPoly(EtherEtherKetone)(PEEK)MoldingandExtrusionMaterials1ThisstandardisissuedunderthefixeddesignationD8033;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thisclassificationsystemcoverspoly(etheretherke-tone)materialssuitableforinjectionmoldingandextrusion.Thisclassificationsystemallowsfortheuseofrecycledmaterialsprovidedthatallspecificationrequirementsaremet.1.2Thepropertiesincludedinthisstandardarethoserequiredtoidentifythecompositionscovered.Otherrequire-mentsnecessarytoidentifyparticularcharacteristicsimportanttospecializedapplicationsaretobespecifiedbyusingthesuffixesinSection5.1.3Thisclassificationsystemandsubsequentlinecallout(specification)areintendedtoprovidemeansofcallingoutpoly(etheretherketone)materialsusedinthefabricationofenditemsorparts.Itisnotintendedfortheselectionofmaterials.Itisrecommendedthatmaterialselectionbemadebythosehavingexpertiseintheplasticsfieldonlyaftercarefulconsid-erationofthedesignandtheperformancerequiredofthepart,theenvironmenttowhichitwillbeexposed,thefabricationprocesstobeemployed,thecostinvolved,andtheinherentpropertiesofthematerialotherthanthosecoveredbythisspecification.1.4Poly(etheretherketone),commonlyreferredtoasPEEK,isamemberofthepoly(aryletherketone)orPAEKfamily.SpecificationD6262coverspropertiesofPAEKshapesandincludesshapesproducedfromPEEK.NOTE1—ThisstandardandISO23153addressthesamesubjectmatter,butdifferintechnicalcontent.1.5Thefollowingprecautionarycaveatpertainsonlytothetestmethodportion,Section11,ofthisclassificationsystem:Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappropriatesafety,health,andenvironmentalpracticesanddeterminetheappli-cabilityofregula...