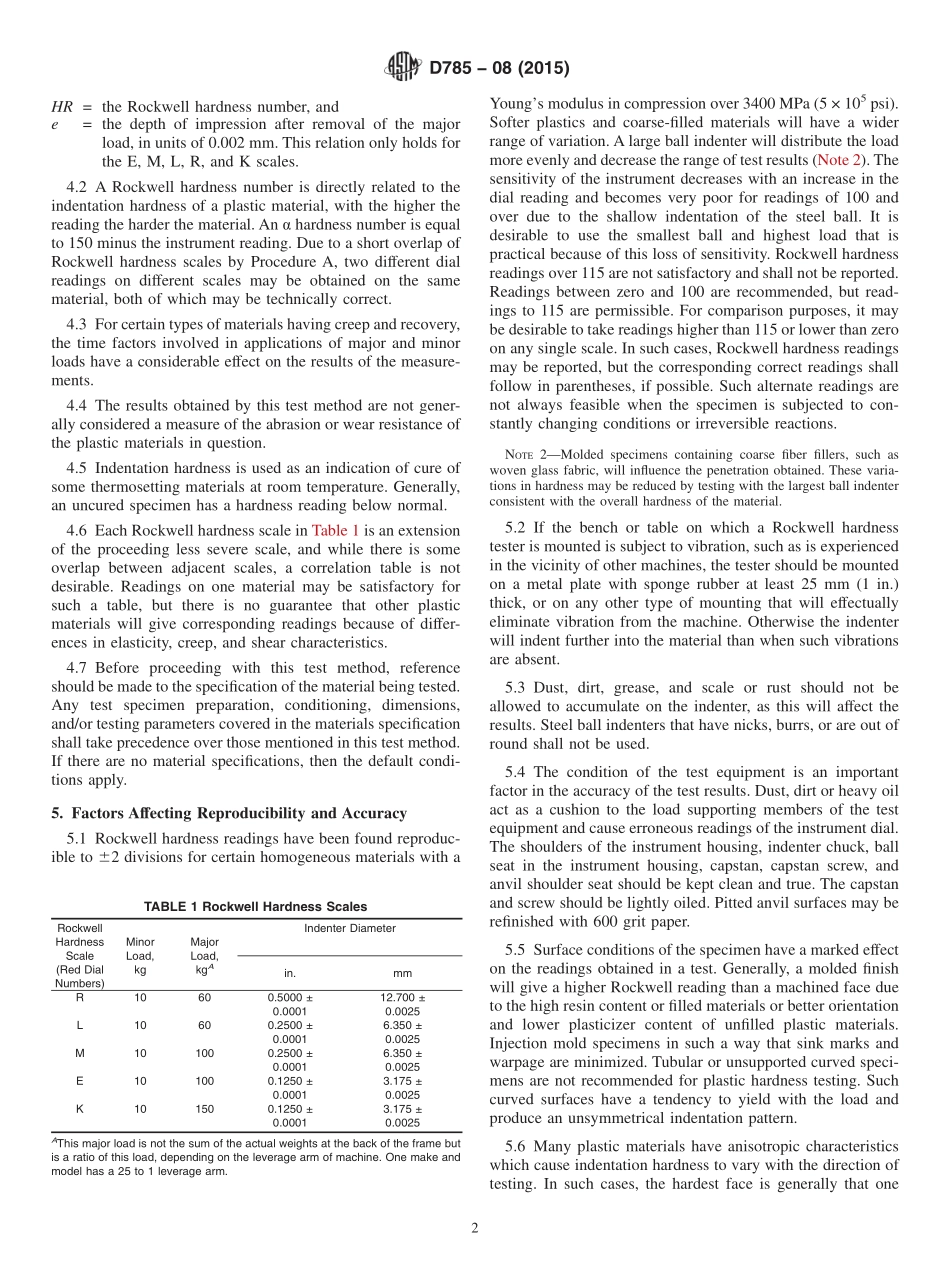

Designation:D785−08(Reapproved2015)StandardTestMethodforRockwellHardnessofPlasticsandElectricalInsulatingMaterials1ThisstandardisissuedunderthefixeddesignationD785;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope1.1ThistestmethodcoverstwoproceduresfortestingtheindentionhardnessofplasticsandrelatedplasticelectricalinsulatingmaterialsbymeansoftheRockwellhardnesstester.1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.NOTE1—ThistestmethodandISO2039-2areequivalent.ProcedureAofthistestmethodisequivalenttothetestmethodinthemainbodyofISO2039-2.ProcedureBofthistestmethodisequivalenttothetestmethodintheintegralannexpartofISO2039-2.2.ReferencedDocuments2.1ASTMStandards:2D618PracticeforConditioningPlasticsforTestingD883TerminologyRelatingtoPlasticsD2240TestMethodforRubberProperty—DurometerHard-nessD4000ClassificationSystemforSpecifyingPlasticMateri-alsE18TestMethodsforRockwellHardnessofMetallicMa-terialsE691PracticeforConductinganInterlaboratoryStudytoDeterminethePrecisionofaTestMethod2.2ISOStandards3ISO2039-2Plastics—DeterminationofHardness—Part2:RockwellHardness3.Terminology3.1DefinitionsusedinthistestmethodareinaccordancewithTerminologyD883.3.2DefinitionsofTermsSpecifictoThisStandard:3.2.1indentationhardness—theresistanceofamaterialtosurfacepenetrationorplasticdeformation.4.SignificanceandUse4.1ARockwellhardnessnumberisanumberderivedfromthenetincreaseindepthimpressionastheloadonanindenterisincr...