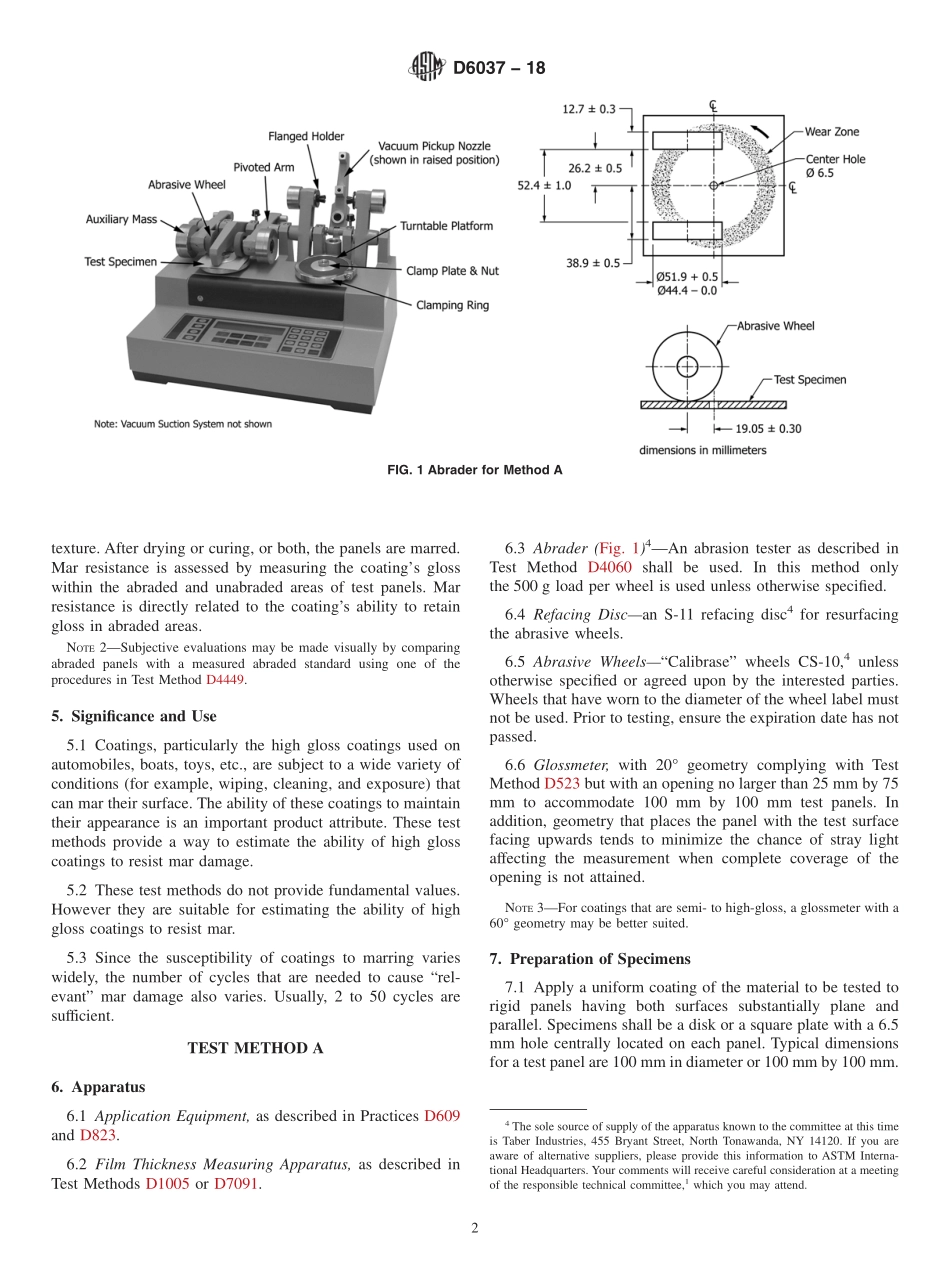

Designation:D6037−18StandardTestMethodsforDryAbrasionMarResistanceofHighGlossCoatings1ThisstandardisissuedunderthefixeddesignationD6037;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope*1.1Thistestmethodcoversproceduresforevaluatingtherelativemarresistanceofhighglosscoatings.Twotestmethodsareincluded.TestMethodAusesadevicethatrotatesthetestspecimenonaverticalaxis,againsttheslidingrotationoftwoabradingwheels.TestMethodBusesadevicethatreciprocatesaspecimeninahorizontalplaneoverastationarywheelthathasbeenfittedwithabrasivepaperandisadvancedaftereachdoublestroke.Eithermethodcanbeusedtoevaluatethedryabrasionmarresistanceofcoatingsappliedtoplanar,rigidsurfaces.Eachtestmethodprovidesgooddiscriminationbetweenhighlymarresistantcoatings.NOTE1—Themarresistancevaluesobtainedbythesetestmethodshavenoabsolutesignificance.Theyshouldonlybeusedtoderiverelativeperformancerankingsfortestpanelsthathavebeenpreparedfromtheseriesofcoatingsthatarecurrentlybeingevaluated.Ifmarresistancevaluesarequotedbetweenlaboratories,itisessentialthatacommonstandardbemeasuredandthatthevaluesbecomparedtothatstandard.Eventhen,thevaluesshouldbeusedwithcaution.1.2ThevaluesstatedinSIunitsaretoberegardedasstandard.Nootherunitsofmeasurementareincludedinthisstandard.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.1.4Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee...