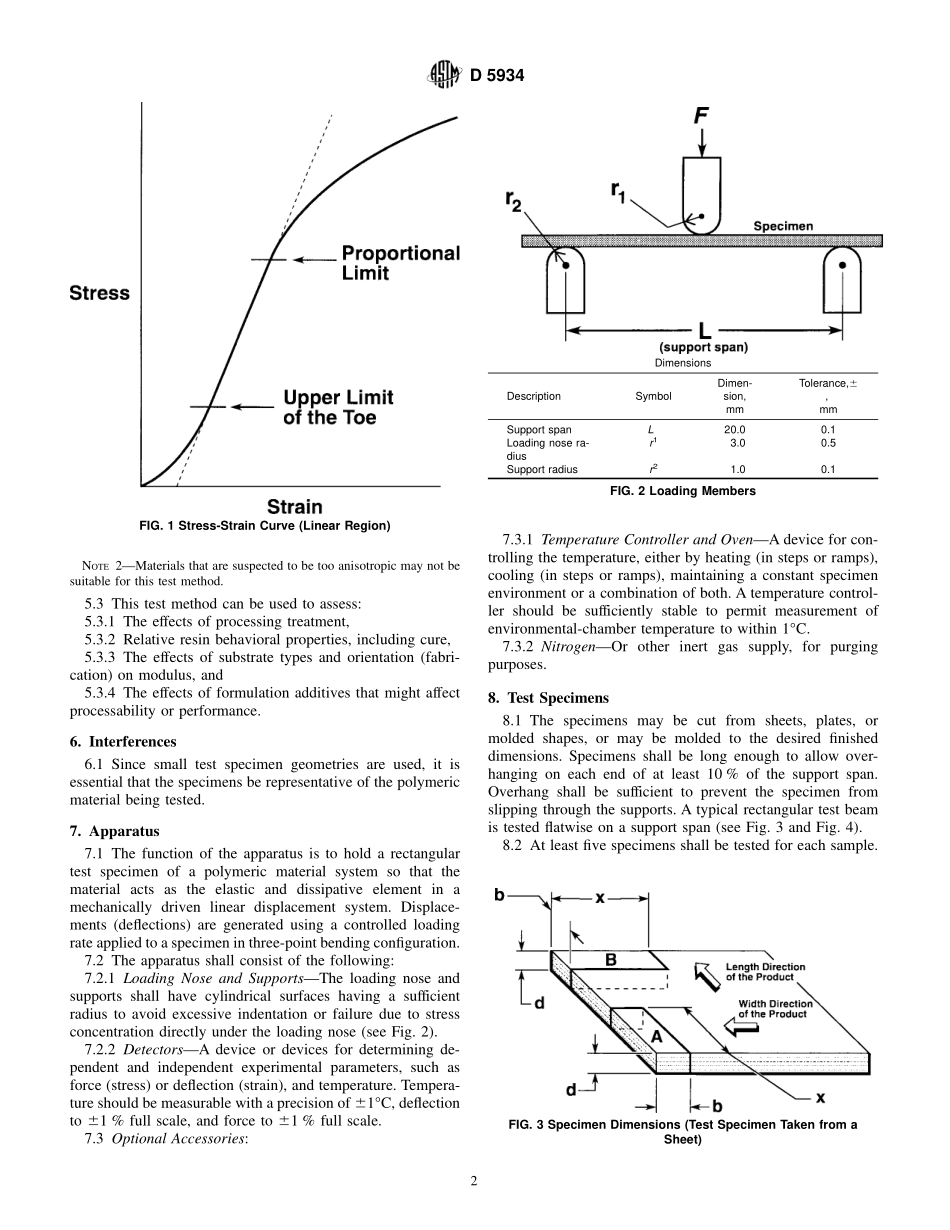

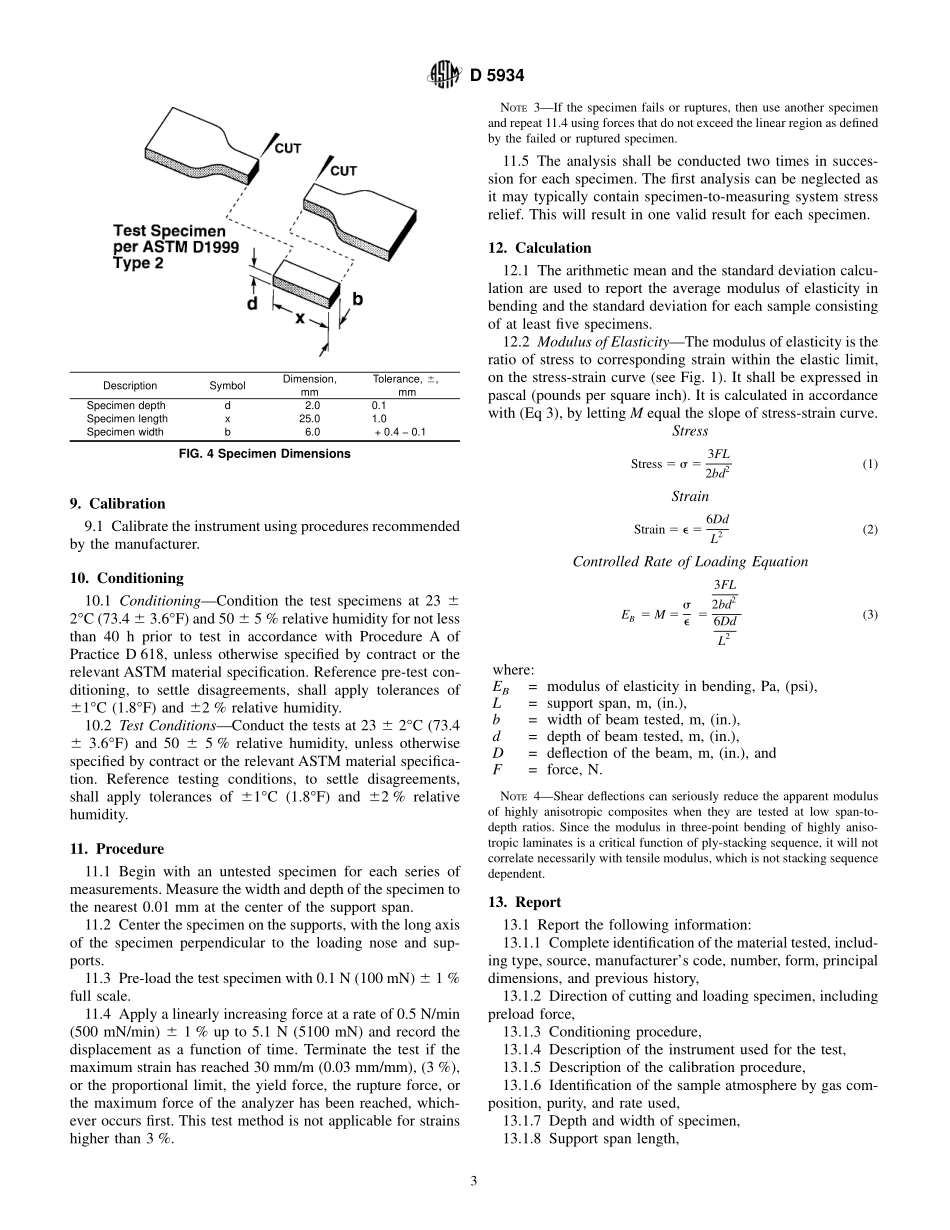

Designation:D5934–02StandardTestMethodforDeterminationofModulusofElasticityforRigidandSemi-RigidPlasticSpecimensbyControlledRateofLoadingUsingThree-PointBending1ThisstandardisissuedunderthefixeddesignationD5934;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(e)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoverstheuseofcontrolledrateofloadingmechanicalinstrumentationforgatheringandreportingthemodulusofelasticityofthermoplasticandthermosettingresinsandcompositesystemsintheformofrectangularbarsmoldeddirectlyorcutfromsheets,plates,ormoldedshapes.Thedatagenerated,usingthree-pointbendingtechniques,maybeusedtoidentifythethermomechanicalpropertiesofaplasticsmaterialorcompositionusingacontrolledrateofloadingmechanicalinstrument.2ResultsobtainedfromthistestmethodmayormaynotbecomparabletoresultsobtainedusingD790.1.2Thistestmethodisintendedtoprovideameansfordeterminingthemodulusofelasticitywithinthelinearregionofthestress-straincurve(seeFig.1).Thistestisconductedatstandardtemperatureandpressure.1.3Apparentdiscrepanciesmayariseinresultsobtainedunderdifferingexperimentalconditions.Theseapparentdiffer-encesfromresultsobservedinanotherstudycanusuallybereconciled,withoutchangingtheobserveddata,byreportinginfull(asdescribedinthistestmethod)theconditionsunderwhichthedatawereobtained.1.4ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesstatedinparenthesesareforinformationonly.1.5Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.NOTE1—ThereisnosimilarorequivalentISOstandard.2.ReferencedDocuments2.1ASTMStandards:D618PracticeforConditioningPlasticsforTesting3D638TestMethodforTensilePropertiesofPlastics3D8...