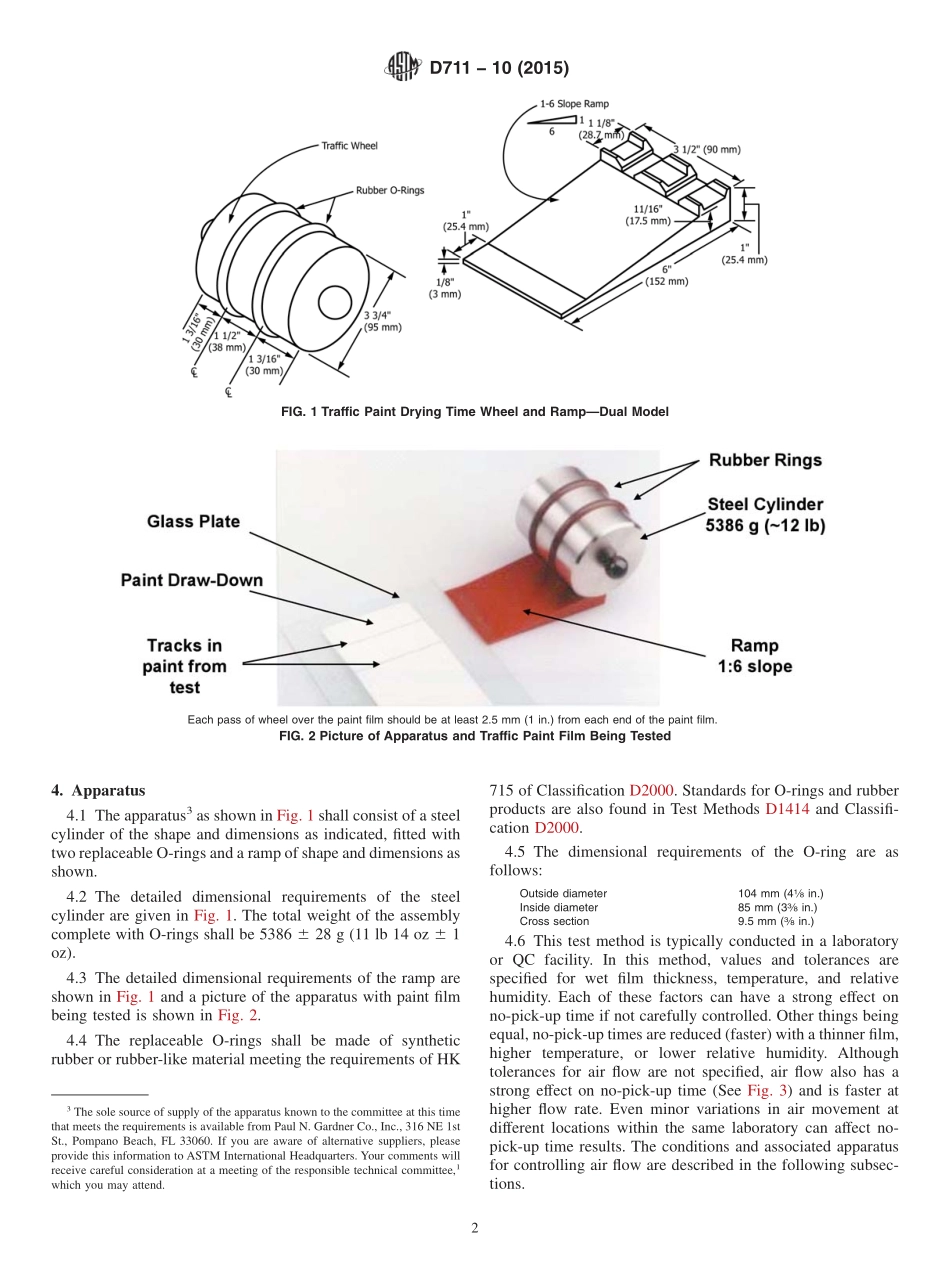

Designation:D711−10(Reapproved2015)StandardTestMethodforNo-Pick-UpTimeofTrafficPaint1ThisstandardisissuedunderthefixeddesignationD711;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.ThisstandardhasbeenapprovedforusebyagenciesoftheU.S.DepartmentofDefense.1.Scope1.1Thistestmethodcoversalaboratoryprocedurefordeterminingtheno-pick-uptimeofatrafficpaint.ThemethodusesawheelconsistingofametalcylinderwithrubberO-rings.Thewheelisrolleddownarampoverafreshlyappliedtrafficpaintfilmrepeatedlyuntilthereisnotransferofpainttotherubberrings.Theelapsedtimefrompaintfilmapplicationtopointofnopainttransferistheno-pick-uptime.Keyvariablestobecontrolledduringtestingarefilmthickness,temperature,humidity,andairflow.1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafetyandhealthpracticesanddeterminetheapplica-bilityofregulatorylimitationspriortouse.2.ReferencedDocuments2.1ASTMStandards:2D823PracticesforProducingFilmsofUniformThicknessofPaint,Varnish,andRelatedProductsonTestPanelsD1212TestMethodsforMeasurementofWetFilmThick-nessofOrganicCoatingsD1414TestMethodsforRubberO-RingsD2000ClassificationSystemforRubberProductsinAuto-motiveApplicationsD4414PracticeforMeasurementofWetFilmThicknessbyNotchGagesD5741PracticeforCharacterizingSurfaceWindUsingaWindVaneandRotatingAnemometer3.SignificanceandUse3.1Thistestmethodservesasalaboratorycontroltest.Typesoftrafficpaintsthatcanbetestedwiththismethodarewaterborne,solventborne,andsome100%solidsliquidtrafficpaints.Thistestismostcommonlyusedwithfast-drywater-bornetrafficpaints.Ifwetfilmthickness,temperature,andhumidityarecontrolledwithinthet...