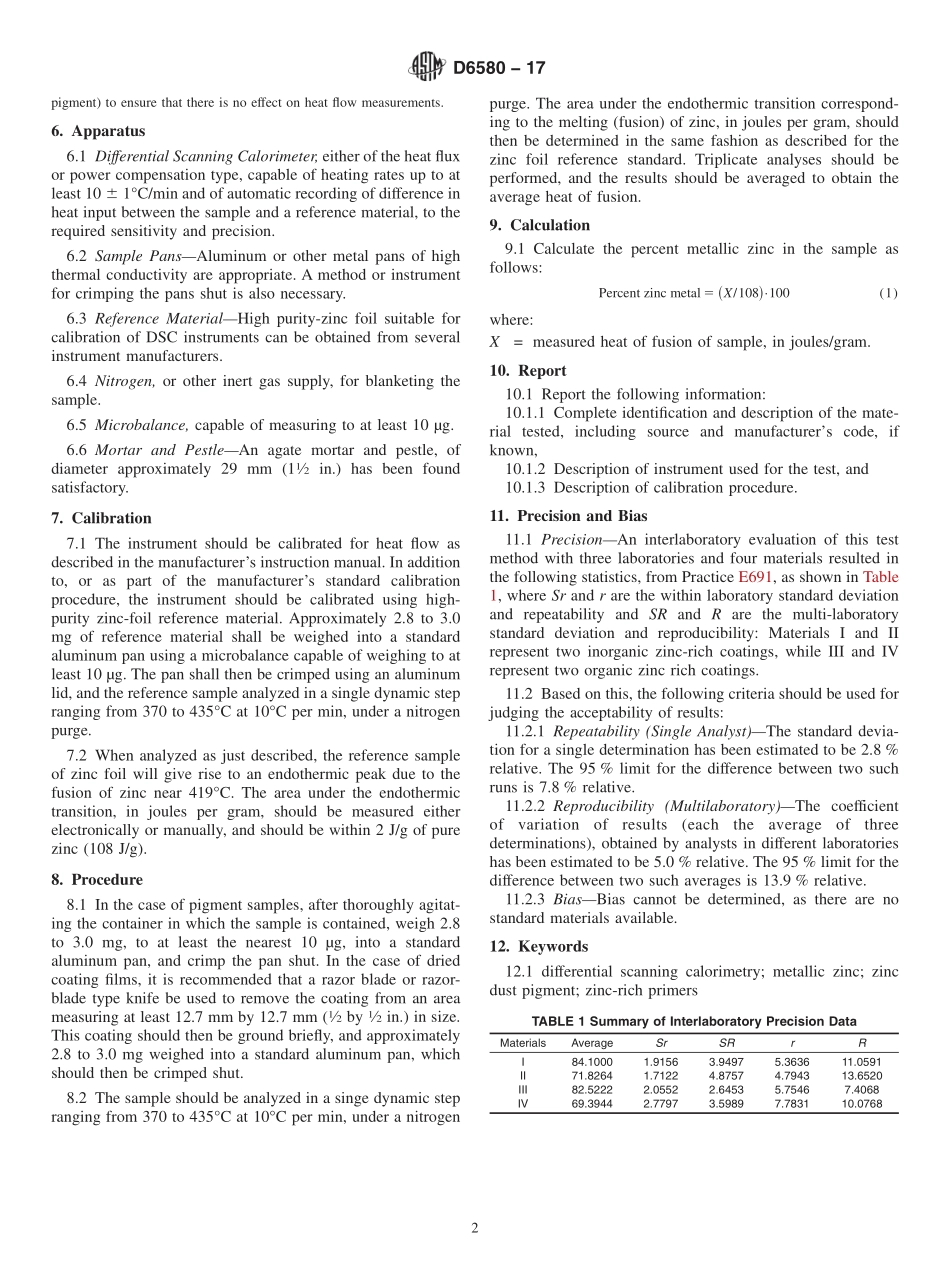

Designation:D6580−17StandardTestMethodforTheDeterminationofMetallicZincContentinBothZincDustPigmentandinCuredFilmsofZinc-RichCoatings1ThisstandardisissuedunderthefixeddesignationD6580;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginaladoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscriptepsilon(´)indicatesaneditorialchangesincethelastrevisionorreapproval.1.Scope1.1Thistestmethodcoversthedeterminationbydifferentialscanningcalorimetryofthemetalliczinccontentofbothzinc-dustpigment,andofdriedfilmsofzinc-richcoatings.Thistestmethodisapplicabletobothinorganicandorganiczinc-richcoatings1.2ThevaluesstatedinSIunitsaretoberegardedasthestandard.Thevaluesgiveninparenthesesareforinformationonly.1.3Thisstandarddoesnotpurporttoaddressallofthesafetyconcerns,ifany,associatedwithitsuse.Itistheresponsibilityoftheuserofthisstandardtoestablishappro-priatesafety,health,andenvironmentalpracticesanddeter-minetheapplicabilityofregulatorylimitationspriortouse.1.4Thisinternationalstandardwasdevelopedinaccor-dancewithinternationallyrecognizedprinciplesonstandard-izationestablishedintheDecisiononPrinciplesfortheDevelopmentofInternationalStandards,GuidesandRecom-mendationsissuedbytheWorldTradeOrganizationTechnicalBarrierstoTrade(TBT)Committee.2.ReferencedDocuments2.1ASTMStandards:2D521TestMethodsforChemicalAnalysisofZincDust(MetallicZincPowder)E691PracticeforConductinganInterlaboratoryStudytoDeterminethePrecisionofaTestMethod3.SummaryofTestMethod3.1Samplesofeitherzinc-dustpigmentorofcuredfilmsofzinc-richcoatingsaregroundinamortarandpestle,thencarefullyweighedintostandarddifferentialscanningcalorim-etry(DSC)samplepans.Thepansarethencrimpedshut,andanalyzedinadifferentialscanningcalorimeterinasingledynamicheatingstep,rangingfrom370to435°Cat10°Cpermin,underanitrogenpurge.Thepercentmetalliczincinthesampleisdeterminedbymeasuringtheenergyassociatedwiththeendothermicpeaknear419°Ccausedbythemeltingofthemetalliczinc...